Plastic Formwork System - Column Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

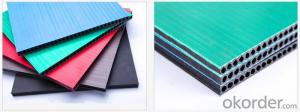

Plastic Formwork System - Column Formwork

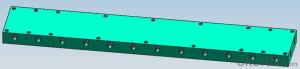

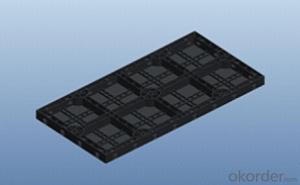

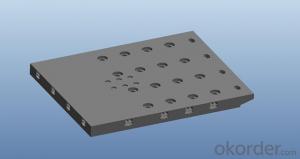

The column panels are interconnected using the standard nylon locking handles. Each panel will require 9 handles. The forming face has 6 parallel rows of fixing holes to allow the orthogonal connection of the panels in a “star” shape. The rows are placed at a distance of 100/50mm the one from the other, allowing the forming of square and/or rectangular columns with side of 150 to 600mm.

light weight, high strength

The material of modular formwork is PP (polypropylene) mixed with special glass fibers which enable panels to hold high pressures.

The handles are made by high strength Nylon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 40cm walls.

product name | Modular formwork |

origin | China |

color | Black |

material | PP |

weight | 11kg |

tensile strength | 40KN |

reusable | 100 times |

Please send your project design drawing in Auto-CAD file to us, we will help to make formwork solution for you.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- It seems to have been the introduction of hollow plastic building template production line (foreign technology), the site last year to see someone used this plastic building template, our site is now using this plastic building template material is polypropylene PP, this template Cheap, suitable for ordinary wall. There is also a material that is made of polycarbonate PC This material is suitable for viaducts, water conservancy works, pouring walls without whitewashing. The wall is very light. It is expensive point.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- Can be ruled length processing, can be ruled length processing, can be ruled length processing

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Plastic building template to be extended when the expansion joints: As the plastic building template than the steel mold, wood mold thermal expansion coefficient larger, morning and evening laying plastic template must be reserved for about 2 mm expansion joints (according to the size of the day the temperature difference ), No need to reserve the expansion of the slit at noon. The length of the nail is generally 1.5 inches to 2 inches is appropriate, not too long or too short.

Send your message to us

Plastic Formwork System - Column Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords