Plastic Formwork Malaysia

Plastic Formwork Malaysia Related Searches

Aluminium Formwork Malaysia Aluminium Formwork Singapore Fabric Formwork System Formwork Singapore Kumkang Aluminium Formwork Peri Formwork Singapore Kumkang Aluminium Formwork System Mfe Aluminium Formwork Materials For Formwork Metal Formwork System Plastic Shapes Plywood Formwork Green Formwork Gliding Formwork Formwork Wall Gass Formwork Moving Formwork Formwork Props Steel Formwork System Formwork System Mfe Formwork India L Shaped Plastic Molding Formwork Installation Foundation Formwork Permanent Formwork System Plastic Netting Uk Concrete Formwork Plywood Striking Formwork Types Of Formwork Ppt System FormworkPlastic Formwork Malaysia Supplier & Manufacturer from China

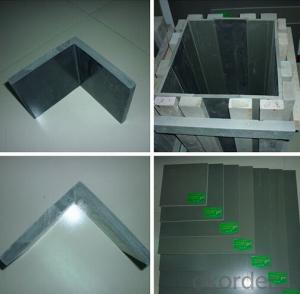

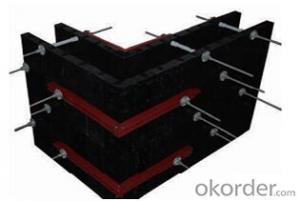

Plastic Formwork Malaysia is a collection of innovative and durable construction materials designed to enhance the efficiency and sustainability of building projects. These products are made from high-quality plastic, offering a lightweight and cost-effective alternative to traditional wooden formwork. They are known for their ability to withstand harsh weather conditions and maintain their shape and integrity over time, making them a popular choice among construction professionals.The application and usage scenarios of Plastic Formwork Malaysia are vast, as they can be utilized in a wide range of construction projects, including residential, commercial, and industrial buildings. These formworks are particularly useful in creating concrete structures such as walls, slabs, and columns, as they provide a smooth and consistent finish. Their versatility also allows them to be used in the construction of bridges, tunnels, and other infrastructure projects. The ease of installation and拆卸 of these formworks contributes to faster construction timelines and reduced labor costs.

Okorder.com is a reputable wholesale supplier of Plastic Formwork Malaysia, boasting a large inventory that caters to the diverse needs of the construction industry. As a leading platform for sourcing high-quality building materials, Okorder.com ensures that customers have access to the latest and most reliable products at competitive prices. Their commitment to customer satisfaction and ongoing support makes them a trusted partner for businesses seeking to optimize their construction processes and achieve better outcomes.

Hot Products