Cost Effective Slab Formwork with Quick - Striking Head Jack

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cost Effective Slab Formwork with Quick - Striking Head Jack

Description:

1. Brief introduction

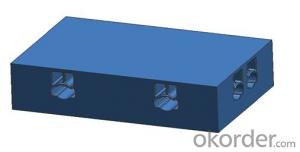

Alu-slab system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, with more important, it can achieve early & quick removing for parts materials; it is good choice for slab construction if you want to do cost effective construction.

3. Competitive advantage

① Cost effective

EA-REMO system has an important member which is called “quick-striking head jack”, with which will achieve quick & early removing for parts formwork system, it is fast to remove and turnover, so EA-REMO system guarantees cost effective construction.

②Flexible application

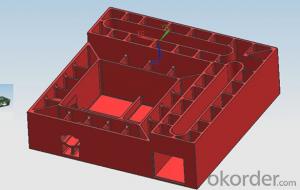

Unlike table formwork, EA-REMO system is composed of scattered element, so comparatively speaking, it will be easily to adapt to different building structures. No matter what shape your structure is, rectangular, circular, cambered, even irregular shape, it will always do a good work.

③Simple structure, easy operation.

The formwork is composed of plywood, main beam, secondary beam, connectors and cup-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

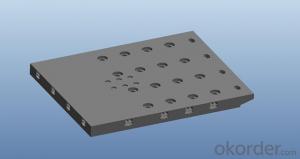

④Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

4. Applications

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- This is mainly to see how the use of workers in the process of operation by standard, 50 times is entirely possible. The use of plastic templates a little bit, the most important thing is to focus on cost savings, integrated plastic template cost is the lowest. But the price is more expensive than the wood template, long-term, large-scale use is cost-effective.

- Q: Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template where there is an urgent need to solve

- Plastic construction template turnover can reach more than 30 times, but also recycling. Temperature to adapt to a large range of specifications adaptability, can be saw, drill, easy to use. Temporal surface of the template, smoothness than the existing technical requirements of the water concrete template, a flame retardant, anti-corrosion, anti-water and anti-chemical corrosion function, have better mechanical properties and electrical insulation properties. Can meet a variety of cuboid, cube, L-shaped, U-shaped building support model requirements.

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

Send your message to us

Cost Effective Slab Formwork with Quick - Striking Head Jack

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords