Cost Effective Slab Formwork System with Quick - Striking Head Jack

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.Concrete slab formwork

2.Cost effective

Cost Effective Slab Formwork System with Quick - Striking Head JackDescription:

Brief introduction

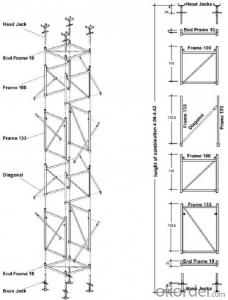

Alu-slab system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, with more important, it can achieve early & quick removing for parts materials; it is good choice for slab construction if you want to do cost effective construction.

Competitive advantage

① Cost effective

EA-REMO system has an important member which is called “quick-striking head jack”, with which will achieve quick & early removing for parts formwork system, it is fast to remove and turnover, so EA-REMO system guarantees cost effective construction.

②Flexible application

Unlike table formwork, EA-REMO system is composed of scattered element, so comparatively speaking, it will be easily to adapt to different building structures. No matter what shape your structure is, rectangular, circular, cambered, even irregular shape, it will always do a good work.

③Simple structure, easy operation.

The formwork is composed of plywood, main beam, secondary beam, connectors and cup-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

④Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

Applications

- Q:How do steel tube couplers prevent tubes from rotating horizontally?

- Steel tube couplers prevent tubes from rotating horizontally by providing a secure and rigid connection between the tubes. These couplers are designed with a tight grip and often include internal teeth or threads that engage with the tubes, preventing any horizontal movement or rotation.

- Q:Are steel tube couplers resistant to impact and shock loads?

- Yes, steel tube couplers are generally resistant to impact and shock loads. The strong and durable nature of steel makes it capable of withstanding high levels of impact and shock without deformation or failure.

- Q:How do steel tube couplers ensure stability and rigidity in scaffolding structures?

- Steel tube couplers ensure stability and rigidity in scaffolding structures by securely connecting and joining the steel tubes together. This creates a strong and interconnected framework that can withstand vertical and horizontal loads, providing a stable and rigid structure for workers to perform tasks safely at various heights.

- Q:Are steel tube couplers suitable for all types of scaffolding systems?

- Due to their versatility and strength, steel tube couplers are widely utilized in various scaffolding systems. They prove suitable for almost all scaffolding systems that utilize steel tubes as the primary structural element. The utilization of steel tube couplers guarantees stability and load-bearing capacity by establishing a reliable and secure connection between scaffolding tubes. These couplers are specifically designed to endure heavy loads, thus providing a safe working platform for laborers. Nevertheless, it is imperative to account for the distinct requirements and regulations of the scaffolding system in use. Certain specialized scaffolding systems may necessitate specific coupler types or connectors to ensure compatibility and safety. Furthermore, factors such as the scaffolding's height, location, and intended purpose should also be taken into consideration when assessing the appropriateness of steel tube couplers. Consulting a qualified scaffolding engineer or supplier can assist in selecting the appropriate couplers for the particular scaffolding system and its intended application.

- Q:Are steel tube couplers suitable for scaffolding projects requiring frequent reassembly or modification?

- Yes, steel tube couplers are suitable for scaffolding projects requiring frequent reassembly or modification. Steel tube couplers are commonly used in construction scaffolding due to their strength and durability. They allow for easy assembly and disassembly, making them ideal for projects that require frequent changes or modifications. These couplers can be quickly and securely connected to steel tubes, providing a reliable and stable structure. Additionally, steel tube couplers can withstand heavy loads and adverse weather conditions, ensuring the safety and stability of the scaffolding. Overall, steel tube couplers are a preferred choice for scaffolding projects that require frequent reassembly or modification.

- Q:What are the typical applications or industries that use steel tube couplers in scaffolding?

- Steel tube couplers are commonly used in the construction industry for various applications, particularly in scaffolding systems. Scaffolding is used to provide a temporary support structure for workers and materials during construction, maintenance, or repair projects. Steel tube couplers play a crucial role in connecting and securing the different components of scaffolding systems. The typical applications or industries that use steel tube couplers in scaffolding include: 1. Construction: Steel tube couplers are extensively used in construction projects of all sizes and types. Whether it's building residential structures, commercial buildings, bridges, or industrial facilities, scaffolding is an integral part of the construction process. Steel tube couplers ensure the stability and safety of the scaffolding structure, allowing workers to carry out their tasks at various heights. 2. Maintenance and Repair: Scaffolding is commonly employed for maintenance and repair work on existing structures such as buildings, bridges, or infrastructure. Steel tube couplers enable the assembly of scaffolding units that can be easily adjusted to fit the specific requirements of each project. This versatility allows workers to access hard-to-reach areas and perform necessary repairs or maintenance tasks effectively. 3. Oil and Gas Industry: The oil and gas industry often relies on scaffolding for various tasks such as construction, maintenance, and inspection of refineries, platforms, and pipelines. Steel tube couplers are crucial in ensuring the stability and strength of scaffolding structures in these harsh environments. They are designed to withstand extreme conditions, including high temperatures, corrosion, and heavy loads. 4. Power and Energy Sector: Power plants and energy facilities require scaffolding during construction, maintenance, and repair work. Steel tube couplers are used to connect the tubes and other components of scaffolding systems, providing a strong and reliable support structure for workers. These couplers can withstand the demanding conditions found in power plants, such as high temperatures and exposure to chemicals. 5. Infrastructure Projects: Infrastructure projects, including roads, bridges, tunnels, and railways, often require scaffolding for construction and maintenance purposes. Steel tube couplers are used extensively in these projects to ensure the safety and stability of scaffolding structures, allowing workers to access different areas for construction or repair work. Overall, steel tube couplers are widely used in the construction, maintenance, and repair industries, particularly in scaffolding applications. They offer a secure and reliable connection between scaffolding components, ensuring the safety and stability of the structure. These couplers are essential in various sectors, including construction, oil and gas, power and energy, and infrastructure projects.

- Q:Are steel tube couplers suitable for both small-scale and large-scale scaffolding projects?

- Yes, steel tube couplers are suitable for both small-scale and large-scale scaffolding projects. They provide a secure and reliable connection between steel tubes, ensuring the stability and strength required for scaffolding structures of any size.

- Q:How do steel tube couplers affect the overall stability and strength of a scaffolding structure?

- Steel tube couplers play a crucial role in enhancing the overall stability and strength of a scaffolding structure. These couplers securely connect the steel tubes and help distribute the load evenly throughout the structure. By providing a strong and reliable connection, they prevent any movement or displacement of the tubes, thereby ensuring the stability of the scaffolding system. Additionally, the couplers reinforce the joints and increase the structural integrity, significantly enhancing the overall strength of the scaffolding structure.

- Q:Are steel tube couplers resistant to compression or crushing forces in scaffolding structures?

- Steel tube couplers are capable of resisting compression or crushing forces in scaffolding structures. Steel, being a robust and durable material, can endure significant pressure and weight. Couplers are specifically designed to securely connect steel tubes, ensuring stability and support for the scaffolding structure. Manufacturers adhere to industry standards while producing these couplers and conduct tests to ascertain their capacity to withstand compression forces. Consequently, steel tube couplers are dependable and can endure the compression or crushing forces that may be applied to scaffolding structures.

- Q:Can steel tube couplers be used in scaffolding projects with limited base support?

- Steel tube couplers can certainly be used in scaffolding projects with limited base support. These couplers are designed to securely connect steel tubes and create a stable structure. However, it is important to consider the specific conditions and requirements of the project. Scaffolding projects with limited base support may face challenges in maintaining stability and load-bearing capacity. In such cases, it is crucial to ensure that the scaffolding is properly designed, engineered, and erected by experienced professionals. This will help to ensure the safety of workers and the overall stability of the structure. Factors such as the height and weight of the scaffolding, the load-bearing capacity of the base support, and the environmental conditions should be taken into account when determining the suitability of steel tube couplers in these projects. If the base support is limited, additional measures may be needed to enhance stability, such as using additional bracing, tie-ins, or other specialized methods. Consulting with a qualified engineer or scaffolding expert can help determine the most appropriate solutions for scaffolding projects with limited base support. Overall, while steel tube couplers can be used in scaffolding projects with limited base support, it is essential to carefully assess the specific conditions and requirements to ensure the safety and stability of the structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cost Effective Slab Formwork System with Quick - Striking Head Jack

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords