Plastic Formworks in Different Kinds of Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of plastic formworks

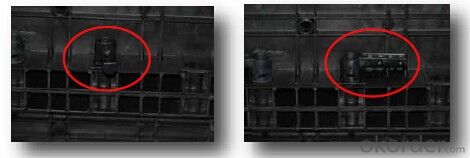

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

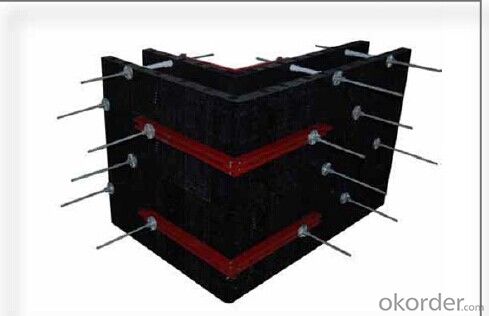

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of plastic formworks

-Light weight

-High strength

-High standardized system

-Easy connection with adjustable steel clamp

-Convenient and fast corner formwork

-Flexible to assemble and application

3. plastic formworks Images

4. plastic formworks Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of plastic formworks

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formworks, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. plastic formworks cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of plastic formworks, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How does steel frame formwork handle the placement of water and wastewater treatment systems within the concrete structure?

- Steel frame formwork is a versatile and reliable method for handling the placement of water and wastewater treatment systems within concrete structures. This type of formwork is specifically designed to support the weight and pressure of these systems, ensuring their proper installation and long-term functionality. One of the key advantages of steel frame formwork is its strength and durability. Steel is known for its high load-bearing capacity, which makes it an ideal choice for supporting the heavy components of water and wastewater treatment systems. Additionally, steel frame formwork provides stability and rigidity to the concrete structure, keeping it intact even under the pressure exerted by these systems. Moreover, steel frame formwork offers flexibility in terms of customization. It can be easily adjusted and modified to fit the specific dimensions and requirements of the water and wastewater treatment systems. This allows for precise placement and alignment of pipes, tanks, and other components within the concrete structure, ensuring efficient operation and easy maintenance of these systems. Another advantage of steel frame formwork is its ability to withstand the corrosive nature of water and wastewater. Steel is highly resistant to corrosion, which is crucial for the long-term durability and reliability of water and wastewater treatment systems. The formwork acts as a protective barrier, preventing the concrete structure from being damaged by the chemicals and corrosive elements present in these systems. In addition to its strength and corrosion resistance, steel frame formwork offers ease of installation and removal. It can be quickly assembled and disassembled, allowing for efficient construction and maintenance processes. This saves time and resources, making it a cost-effective solution for handling the placement of water and wastewater treatment systems within concrete structures. Overall, steel frame formwork is a robust and efficient method for handling the placement of water and wastewater treatment systems within concrete structures. Its strength, durability, flexibility, and resistance to corrosion make it an ideal choice for ensuring the proper installation and functionality of these systems, contributing to the overall success of water and wastewater treatment projects.

- Q: Can steel frame formwork be used for both small and large-scale bridge construction projects?

- Steel frame formwork is suitable for both small and large-scale bridge construction projects, offering numerous advantages. Firstly, steel's strength and durability enable it to withstand the heavy loads and stresses associated with bridge construction, providing the necessary support and stability for both small and large-scale bridges. Furthermore, steel frame formwork is highly adaptable and flexible, allowing for customization to different bridge designs and dimensions. This versatility makes it suitable for constructing bridges of varying sizes and complexities. In addition to its adaptability, steel frame formwork is known for its efficiency and ease of use. It can be easily assembled, disassembled, and reused, saving time and reducing costs associated with formwork materials. Moreover, steel frame formwork ensures the structural integrity and aesthetic appeal of the bridge through its excellent concrete finish. The smooth and even surface it creates helps achieve the desired quality and appearance of the bridge. In conclusion, steel frame formwork is a suitable choice for both small and large-scale bridge construction projects due to its strength, versatility, efficiency, and ability to provide a high-quality finish.

- Q: What are the different types of alignment systems used with steel frame formwork?

- Steel frame formwork commonly utilizes various types of alignment systems to achieve accurate and precise alignment of the formwork components, enabling the construction of straight and level concrete structures. Some of these alignment systems include the following: 1. Adjustable Alignment Bolts: This widely used system involves the installation of adjustable bolts at the corners of the steel frame formwork. By adjusting these bolts, the formwork can be leveled and aligned properly. 2. Alignment Clamps: To maintain the alignment of the formwork panels during the concrete pour, alignment clamps are employed. These clamps securely hold the panels together, preventing any movement or shifting during the construction process. 3. Alignment Pins: Alignment pins are inserted into pre-drilled holes in the formwork panels, aligning and connecting them securely. These pins ensure that the panels are properly aligned and firmly joined together. 4. Alignment Wedges: Alignment wedges are used to adjust and align the steel frame formwork panels. They are inserted between the panels and can be easily adjusted to ensure levelness and proper alignment. 5. Magnetic Alignment Systems: This type of alignment system utilizes powerful magnets to hold the formwork panels in place and maintain their alignment. Particularly advantageous for steel frame formwork, the magnets create a strong and secure connection between the panels. In summary, the diverse range of alignment systems used with steel frame formwork is designed to guarantee precise alignment and accuracy of the formwork components. These systems are instrumental in achieving the desired quality and finish of concrete construction projects.

- Q: What are the different methods of releasing the formwork from the concrete surface?

- There are several methods of releasing formwork from the concrete surface. These include using form release agents, applying a thin layer of oil or grease on the formwork, using water-based release agents, using mechanical methods such as vibrating or tapping the formwork, and using thermal methods such as heating or cooling the formwork. Each method has its own advantages and considerations depending on the specific project and requirements.

- Q: Can steel frame formwork be used for the construction of precast concrete elements?

- Yes, steel frame formwork can be used for the construction of precast concrete elements. Steel frame formwork is a versatile and durable system that can be easily customized to different shapes and sizes of precast elements. It provides the necessary support and stability during the pouring and curing process of precast concrete. The steel frame formwork system allows for efficient and precise construction of precast elements, ensuring high-quality and consistent results. Additionally, steel frame formwork can be reused multiple times, making it a cost-effective choice for precast concrete construction projects.

- Q: How does steel frame formwork handle the movement and settlement of a structure?

- Steel frame formwork is a construction technique that uses steel frames to support the concrete during the pouring and curing process. One of the main advantages of using steel frame formwork is its ability to handle the movement and settlement of a structure. Steel has high tensile strength, which means it can withstand the forces caused by movement and settlement without deforming or failing. This is crucial in construction, as buildings are subject to various types of movement and settlement over time. Firstly, steel frame formwork provides a rigid structure that supports the weight of the concrete and distributes it evenly across the foundation. This helps to minimize any uneven settlement or movement that may occur. Additionally, steel frame formwork is designed to be flexible and adjustable. It can accommodate slight variations in the structure's dimensions, allowing for some movement without compromising its integrity. This flexibility is particularly important in areas with high seismic activity, where structures need to be able to withstand earthquakes and other ground movements. Moreover, steel frame formwork is often equipped with expansion joints. These joints allow the structure to expand and contract naturally without causing any damage. Expansion joints are crucial in areas with extreme temperature fluctuations, as they prevent the steel and concrete from cracking due to thermal expansion. In summary, steel frame formwork handles the movement and settlement of a structure by providing a strong and flexible support system. Its high tensile strength, adjustability, and inclusion of expansion joints make it ideal for withstanding the forces and movements that a building may experience throughout its lifespan.

- Q: Can steel frame formwork be used for both interior and exterior slab construction?

- Yes, steel frame formwork can be used for both interior and exterior slab construction. Its sturdy and durable structure allows it to withstand the pressures and forces exerted during concrete pouring and curing, making it suitable for various construction applications, regardless of whether they are indoors or outdoors.

- Q: How does steel frame formwork differ from other types of formwork?

- Steel frame formwork differs from other types of formwork in several ways. Firstly, steel frame formwork is made of steel, which makes it extremely strong and durable. It can withstand heavy loads and is resistant to warping or bending. This makes it ideal for construction projects that require a high level of strength and stability. Secondly, steel frame formwork is highly versatile. It can be easily customized and adjusted to fit different shapes and sizes of structures. This flexibility allows for the creation of complex and unique designs that may not be possible with other types of formwork. Additionally, steel frame formwork offers superior stability and accuracy. The steel frames provide excellent support and ensure that the formwork remains in place and does not shift during the pouring and curing of concrete. This results in better quality and more precise construction. Furthermore, steel frame formwork has a longer lifespan compared to other types of formwork. Its durability and resistance to wear and tear mean that it can be used for multiple projects, making it a cost-effective option in the long run. Lastly, steel frame formwork is relatively quick and easy to assemble and dismantle. The steel frames can be easily transported and assembled on-site, saving time and labor costs. This efficiency is especially beneficial for projects with tight deadlines or limited resources. In summary, steel frame formwork stands out from other types of formwork due to its strength, versatility, stability, durability, and ease of use. These qualities make it an excellent choice for construction projects that require a high level of performance and efficiency.

- Q: What are the considerations for selecting the appropriate formwork height and width?

- There are several factors to consider when choosing the right height and width for formwork. Firstly, the dimensions and specifications of the structure being built should determine the height and width of the formwork. Careful measurements and calculations are necessary to ensure that the formwork can accommodate the desired shape and size of the concrete structure. Another important factor is the load-bearing capacity of the formwork. It must be able to withstand the weight and pressure of the concrete, as well as any additional loads during construction. It is crucial to select strong and durable formwork that can safely support the weight and pressure without any deflection or failure. The type of construction method being used is also a consideration. Different methods may require different formwork systems with varying dimensions. For instance, the formwork may need to be taller and wider for the construction of a high-rise building. Ease of installation and removal is another important consideration. The formwork should be easy to assemble and disassemble, saving time and labor. It should also be flexible enough to allow for adjustments and modifications as needed. Cost is another factor to consider. Different types of formwork have different costs, so it is important to choose a cost-effective system that still meets the necessary specifications and safety standards. Lastly, the availability and accessibility of the formwork system should be taken into account. It is important to select a system that is readily available in the market and can be easily sourced. This ensures a smooth construction process without delays in material procurement. In conclusion, when selecting the appropriate formwork height and width, it is important to consider the dimensions and specifications of the structure, the load-bearing capacity, the construction method, the ease of installation and removal, the cost, and the availability of the formwork system. Considering these factors will help in choosing the most suitable formwork system for the construction project.

- Q: How does steel frame formwork affect the overall flexibility of construction schedules?

- Steel frame formwork can have a positive impact on the overall flexibility of construction schedules. This is primarily due to the efficiency and speed at which steel frame formwork can be assembled and disassembled. Compared to other types of formwork, steel frame formwork is known for its durability and strength. It can withstand high pressures and loads, allowing for faster construction processes. This means that construction projects using steel frame formwork can be completed in shorter time frames, which in turn provides more flexibility in scheduling. Furthermore, steel frame formwork is highly versatile and can be easily adjusted to accommodate changes in design or modifications during construction. This adaptability allows for greater flexibility in construction schedules as adjustments can be made quickly and efficiently. In addition, the use of steel frame formwork reduces the reliance on traditional timber formwork, which may require longer curing times for concrete. Steel frame formwork allows for faster concrete pouring and curing, thus speeding up the construction process and providing greater flexibility in scheduling. Overall, the use of steel frame formwork positively affects the overall flexibility of construction schedules by allowing for faster construction, easier modifications, and reduced curing times. This enables construction projects to be completed more efficiently and provides the opportunity to adjust schedules as needed.

Send your message to us

Plastic Formworks in Different Kinds of Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords