New Invented Plastic Formworks in Construction Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

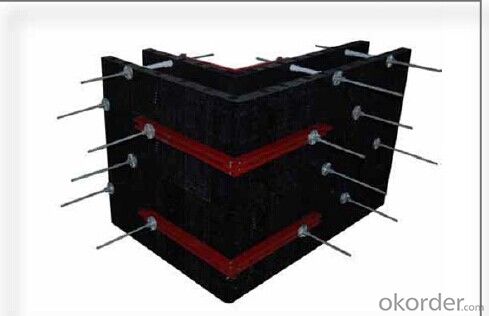

1. Structure of plastic formworks

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of plastic formworks

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. plastic formworks Images

4. plastic formworks Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of plastic formworks

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formworks, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. plastic formworks cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of plastic formworks, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What are the different types of steel used in steel frame formwork systems?

- There are several types of steel commonly used in steel frame formwork systems. The choice of steel depends on factors such as load capacity, durability, and cost. 1. Mild Steel: This is the most common type of steel used in formwork systems. It is known for its strength and affordability. Mild steel is suitable for most construction applications and can handle moderate loads. 2. High-Strength Low-Alloy (HSLA) Steel: HSLA steel is a type of steel that offers higher strength and better corrosion resistance compared to mild steel. It is commonly used in applications that require increased load capacity and durability. 3. Alloy Steel: Alloy steel is made by adding elements such as chromium, nickel, or molybdenum to improve its mechanical properties. It offers increased strength, hardness, and resistance to wear and tear. Alloy steel is often used in heavy-duty formwork systems that require high load-bearing capacity. 4. Stainless Steel: Stainless steel is known for its excellent corrosion resistance. It is commonly used in formwork systems that are exposed to harsh environments, such as marine or chemical plants. Stainless steel is more expensive than other types of steel but provides long-lasting performance. 5. Carbon Steel: Carbon steel is a type of steel that contains carbon as the main alloying element. It offers good strength and durability, making it suitable for various formwork applications. Carbon steel is also commonly used in combination with other materials, such as concrete, to provide additional reinforcement. It is important to select the appropriate type of steel for a steel frame formwork system based on the specific requirements of the construction project. Factors such as load capacity, durability, and budget should be considered to ensure the success of the formwork system.

- Q: What types of projects are steel frame formwork suitable for?

- Steel frame formwork is suitable for a wide range of construction projects, particularly those that require a strong and durable formwork system. Some of the projects that steel frame formwork is commonly used for include high-rise buildings, bridges, tunnels, dams, and large-scale infrastructure projects. Due to its robustness and ability to withstand heavy loads, steel frame formwork is an ideal choice for projects that involve pouring concrete in large quantities or require a high level of structural integrity. The steel frame provides excellent support and stability, ensuring that the formwork system can withstand the pressure exerted by the wet concrete. Furthermore, steel frame formwork is highly adaptable and can be easily customized to suit different project requirements. It can be adjusted to accommodate various shapes, sizes, and dimensions, making it suitable for projects that involve complex architectural designs or unique structural elements. Additionally, steel frame formwork is reusable, which makes it a cost-effective option for projects that require repetitive casting of concrete elements. In summary, steel frame formwork is well-suited for projects that demand strength, durability, and versatility. Its ability to handle heavy loads, adapt to various shapes, and be reused makes it an excellent choice for high-rise buildings, bridges, tunnels, dams, and large-scale infrastructure projects.

- Q: Does steel frame formwork require any specific vibration techniques for concrete compaction?

- Concrete compaction when using steel frame formwork necessitates the application of specific vibration techniques. Steel frame formwork is a construction system that supports newly poured concrete and guarantees its desired shape. In order to eliminate air voids and promote adequate bonding between the concrete and reinforcement, the concrete within the formwork must be compacted. Vibration serves as a crucial compaction method. By removing trapped air bubbles, vibration prevents concrete weakness and reduces the risk of decreased strength. Additionally, vibration facilitates the even distribution and consistent density of the concrete in all corners and tight spaces of the formwork. For effective compaction with steel frame formwork, it is advisable to employ either internal vibrators or external vibrators. Internal vibrators, also referred to as immersion or poker vibrators, are vertically inserted into the concrete at regular intervals. These vibrators generate high-frequency vibrations that consolidate the concrete. On the other hand, external vibrators are affixed to the formwork itself. They produce vibrations that are transmitted to the concrete via the formwork. External vibrators are commonly used for larger areas or when a uniform vibration is necessary. The specific techniques for concrete compaction with steel frame formwork are contingent upon variables such as the concrete mix design, formwork dimensions, and desired finish. Adhering to the manufacturer's guidelines and employing best practices for vibration techniques is essential. In conclusion, specific vibration techniques are required for concrete compaction when using steel frame formwork. These techniques involve the utilization of internal or external vibrators to ensure proper consolidation and eliminate air voids within the freshly poured concrete. By following recommended practices and guidelines, a durable and high-quality concrete structure can be achieved.

- Q: Can steel frame formwork be used for both interior and exterior concrete structures?

- Yes, steel frame formwork can be used for both interior and exterior concrete structures. Steel frame formwork is highly versatile and can be customized to meet the specific requirements of various construction projects. It provides a strong and durable support system for pouring concrete and is capable of withstanding the pressures exerted during the concrete curing process. Whether it is for interior walls, columns, or exterior structures such as beams and slabs, steel frame formwork can be easily adapted and installed. Its flexibility, strength, and stability make it a popular choice for construction projects of all types and sizes.

- Q: Can steel frame formwork be used in areas with limited access to utilities?

- Steel frame formwork is capable of being utilized in areas with restricted access to utilities. Unlike traditional formwork systems, which rely on water and electricity for setup and removal, steel frame formwork is designed to be easily assembled and disassembled without the need for additional utilities. This adaptable and portable solution can be employed in remote locations or areas where access to utilities is restricted. Typically lightweight, steel frame formwork can be manually transported to the site or with minimal machinery, making it suitable for areas with limited infrastructure. Furthermore, steel frame formwork can be reused multiple times, decreasing the necessity for a constant supply of utilities during construction. In conclusion, steel frame formwork offers a pragmatic and effective solution for construction projects in areas with limited access to utilities.

- Q: How does steel frame formwork contribute to the overall sustainability of a construction project?

- There are several ways in which the use of steel frame formwork contributes to the overall sustainability of a construction project. To begin with, steel is an extremely durable material that can withstand the demands of construction. This durability ensures that the formwork system will last a long time, reducing the need for frequent replacements. As a result, there is a decrease in waste generation and resource consumption. Furthermore, unlike traditional timber formwork that is often discarded after one use, steel frame formwork can be dismantled and reused multiple times. This significantly reduces material waste and minimizes the environmental impact of the construction process. Moreover, steel is a recyclable material. Once it reaches the end of its useful life as formwork, steel frames can be recycled and used to create new steel products. This helps to reduce the demand for new materials and conserve natural resources. In addition, steel frame formwork offers flexibility in design and construction. Its modular nature allows for easy customization and adjustment, minimizing the need for excessive material cutting and reducing construction waste. This adaptability also ensures efficient resource use and decreases the overall environmental footprint of the project. Furthermore, steel frame formwork enables faster construction compared to traditional formwork systems. This results in reduced energy consumption, lower carbon emissions, and a smaller environmental impact. In conclusion, the use of steel frame formwork promotes sustainability in construction projects by promoting durability, reusability, recyclability, flexibility, and efficiency. By incorporating steel frame formwork, construction projects can minimize waste, conserve resources, reduce carbon emissions, and create more sustainable built environments.

- Q: Can steel frame formwork be used for retrofitting or renovation projects?

- Retrofitting or renovation projects can effectively utilize steel frame formwork. This versatile and durable system is commonly employed in various construction projects, including retrofitting and renovation endeavors. Designed to offer support and structure during the concrete pouring and curing process, steel frame formwork proves beneficial. In retrofitting or renovation projects, steel frame formwork serves multiple purposes. It can create new concrete structures or reinforce and repair existing ones. Whether it involves constructing walls, beams, columns, slabs, or reinforcing pre-existing elements, steel frame formwork can handle the task. One advantage of utilizing steel frame formwork in retrofitting projects is its ability to provide a sturdy and stable support system, ensuring proper pouring and curing of concrete. Moreover, it can be easily adjusted and repositioned to accommodate design and construction flexibility. Another benefit of steel frame formwork is its reusability, making it a cost-effective and environmentally friendly option. It can be effortlessly dismantled and utilized in multiple projects, reducing waste and conserving resources. In conclusion, steel frame formwork is an efficient and fitting solution for retrofitting or renovation projects. It offers the necessary support and structure for concrete elements while providing flexibility, durability, and cost-effectiveness.

- Q: Airtight door and all glass steel frame door which cost is high

- If you want to choose between the two, it is necessary to combine their own actual situation.

- Q: What are the considerations for selecting the appropriate formwork for different concrete mixes?

- When selecting the appropriate formwork for different concrete mixes, there are several considerations to keep in mind. These include the type and strength of the concrete mix, the desired finish of the concrete surface, the complexity of the structure being built, the required level of accuracy, and the duration of the project. Other factors may include the availability and cost of the formwork materials, the ease of assembly and removal, and the level of skill and experience of the construction team. Ultimately, the goal is to choose a formwork system that can safely and efficiently support the concrete during the pouring and curing process, while also providing the desired finish and meeting the project's specific requirements.

- Q: How does steel frame formwork provide stability during concrete pouring?

- Steel frame formwork provides stability during concrete pouring through its strong and rigid structure. The steel frame acts as a support system, holding the formwork in place and preventing any deformation or collapse during the pouring process. One key feature of steel frame formwork is its ability to withstand the pressure exerted by the wet concrete. The steel frames are designed to be robust and durable, capable of withstanding the weight and force of the concrete as it is being poured. This ensures that the formwork remains stable and intact, providing a secure and reliable structure for the concrete to be poured into. Additionally, steel frame formwork is often equipped with adjustable props or supports, which further enhance its stability. These props allow for easy adjustment and leveling of the formwork, ensuring that it remains perfectly aligned and in position during the pouring process. This eliminates the risk of any movement or shifting of the formwork, which could compromise the quality and integrity of the concrete structure. Furthermore, steel frame formwork is designed with interlocking mechanisms that provide additional stability. These interlocking components enable the formwork to be securely connected to each other, creating a rigid and cohesive system. This prevents any gaps or spaces from forming between the formwork panels, ensuring a uniform and consistent concrete pour. Overall, the strong and sturdy nature of steel frame formwork, combined with its adjustable props and interlocking mechanisms, provides the necessary stability to withstand the forces and pressures exerted during concrete pouring. This ensures a safe and efficient pouring process, resulting in a high-quality and structurally sound concrete structure.

Send your message to us

New Invented Plastic Formworks in Construction Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords