Steel Fram Formworks Used for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork GK120 Description

There is a prizing part designed in the corner, which can help to position and remove formwork easily.The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

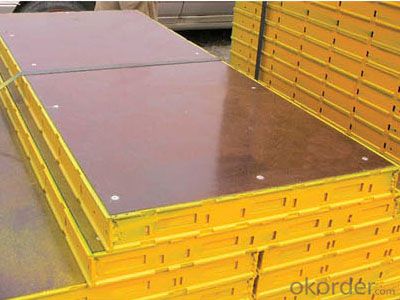

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120Specifications

Steel Frame Formwork GK120 is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the Steel Frame Formwork GK120 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Can steel frame formwork be used for both straight and curved slabs?

- Yes, steel frame formwork can be used for both straight and curved slabs. The steel frames can be easily adjusted to create the desired shape and can withstand the pressure of concrete, making it a versatile option for various slab designs.

- Q: What is the average lifespan of a steel frame formwork system?

- The average lifespan of a steel frame formwork system can vary depending on various factors such as the quality of the materials used, the frequency and intensity of usage, and the maintenance and care provided. Generally, a well-maintained steel frame formwork system can last for several years, ranging from 10 to 20 years or even longer. It is important to note that regular inspections and repairs, as well as proper storage and handling, can significantly extend the lifespan of the system. Additionally, factors such as weather conditions, exposure to corrosive agents, and proper load distribution can also impact the longevity of a steel frame formwork system.

- Q: ANSYS steel frame structure modeling, commonly used in size, density, Poisson's ratio is much better? Help。

- Steel structure with a long time carbon structural steel, the size of the size of the steel you actually use

- Q: Are there any safety considerations associated with steel frame formwork?

- Yes, there are several safety considerations associated with steel frame formwork. Firstly, steel frame formwork is heavy and requires proper handling and lifting techniques to avoid musculoskeletal injuries. Workers should receive adequate training on the proper use of lifting equipment and techniques to prevent strains and sprains. Additionally, steel frame formwork often requires workers to work at height, which poses fall hazards. It is essential to have proper fall protection measures in place, such as safety harnesses, guardrails, and safety nets, to prevent falls and protect workers from serious injuries or fatalities. Another safety consideration is the stability of the steel frame formwork. It is important to ensure that the formwork is properly braced and secured to prevent collapse or movement during concrete pouring and curing. Regular inspections should be conducted to identify and address any potential stability issues. Furthermore, steel formwork can be prone to corrosion if not properly maintained. Rust and corrosion can weaken the structure and compromise its safety. Regular inspections and maintenance, such as cleaning, painting, and applying anti-corrosion treatments, are necessary to ensure the integrity and safety of the steel frame formwork. Lastly, proper communication and coordination among workers is crucial to prevent accidents and injuries. Clear instructions, safety briefings, and regular communication channels should be established to ensure everyone understands their roles and responsibilities and can work together safely. Overall, while steel frame formwork offers many benefits, it is important to be aware of and address the safety considerations associated with its use to protect workers and maintain a safe working environment.

- Q: How does steel frame formwork contribute to the overall constructability of a concrete structure?

- Steel frame formwork plays a crucial role in enhancing the overall constructability of a concrete structure. Its contribution can be observed in several key areas. Firstly, steel frame formwork provides a sturdy and durable framework for pouring and shaping the concrete. The steel frames are designed to withstand the pressure exerted by the liquid concrete, ensuring that it maintains its shape and integrity during the pouring process. This stability is essential for achieving precise and accurate dimensions in the final structure. Additionally, steel frame formwork allows for efficient and speedy construction. Its modular design enables easy assembly and disassembly, reducing the time required for formwork installation and removal. This time-saving aspect is especially beneficial in large-scale construction projects, where the ability to quickly move formwork from one area to another can significantly expedite the overall construction timeline. Moreover, steel frame formwork facilitates flexibility and adaptability during the construction process. The modular components can be adjusted and reconfigured to accommodate various architectural and design requirements. This versatility allows for the creation of complex structures with unique shapes and dimensions. Furthermore, steel frame formwork contributes to the overall safety of the construction site. The robustness of the steel frames ensures that the formwork can withstand external forces such as wind or vibrations, reducing the risk of accidents or collapse. Additionally, the use of steel formwork eliminates the need for excessive propping, further enhancing the safety of the construction site. In conclusion, steel frame formwork greatly enhances the constructability of a concrete structure by providing stability, efficiency, flexibility, and safety. Its durable framework, modular design, and adaptability contribute to the accurate and timely construction of high-quality concrete structures.

- Q: Does steel frame formwork require any special maintenance?

- Yes, steel frame formwork does require some special maintenance. Firstly, after each use, the formwork needs to be properly cleaned to remove any concrete residue or debris that may have accumulated. This can be done using high-pressure water or wire brushes. Additionally, any rust or corrosion that may have developed on the steel frame should be treated and removed to prevent further damage. It is also important to regularly inspect the formwork for any signs of wear and tear, such as cracks, dents, or bent components. Any damaged parts should be repaired or replaced to ensure the formwork's structural integrity and safety. Furthermore, proper storage is crucial to maintaining the quality and longevity of steel frame formwork. The formwork should be stored in a dry and well-ventilated area to prevent moisture buildup and corrosion. It is also advisable to coat the steel frame with a rust-resistant paint or protective coating to provide an additional layer of protection against environmental factors. Regular maintenance and upkeep of steel frame formwork will not only extend its lifespan but also ensure its reliability and safety during construction projects.

- Q: Can steel frame formwork be used for both rectangular and irregularly shaped concrete elements?

- Both rectangular and irregularly shaped concrete elements can be constructed using steel frame formwork. This versatile and flexible system can be easily adjusted and customized to accommodate different shapes and sizes. It is composed of steel frames, panels, and accessories that can be assembled in various configurations to create the desired formwork shape. The strength and stability of the steel frames allow the formwork to withstand the pressure exerted by the wet concrete during pouring and curing. Furthermore, the panels can be easily adjusted or cut to fit irregular shapes, making it suitable for constructing elements with non-standard geometries. In summary, steel frame formwork is an reliable and effective solution for constructing both rectangular and irregularly shaped concrete elements.

- Q: How does steel frame formwork prevent concrete shrinkage and cracking?

- Steel frame formwork prevents concrete shrinkage and cracking by providing strong support and reinforcement to the concrete structure. The steel frame acts as a rigid and stable framework, ensuring that the concrete remains in its intended shape during curing. This prevents excessive shrinkage and cracking that may occur due to internal stresses or inadequate support. Additionally, the steel frame formwork allows for proper alignment and placement of reinforcement bars, further increasing the strength and durability of the concrete structure.

- Q: How does steel frame formwork help in achieving a smooth concrete finish?

- Achieving a smooth concrete finish is made possible with the use of steel frame formwork. This formwork system provides a sturdy and stable structure for pouring the concrete, preventing any sagging or bulging. It ensures that the concrete retains its desired shape and surface finish. The formwork is constructed from top-notch steel, renowned for its strength and durability. This guarantees that it can withstand the pressure exerted by the wet concrete without bending or distorting. Consequently, the concrete sets evenly and smoothly, minimizing any imperfections or irregularities on the surface. Moreover, the steel frame formwork system allows for precise control over concrete placement and compaction. The formwork can be adjusted and aligned to the desired dimensions and angles, ensuring accurate pouring. This eliminates the need for excessive manual finishing or leveling, resulting in a smoother and more consistent finish. Furthermore, the steel frame formwork also minimizes the risk of formwork marks or imprints on the concrete surface. The steel panels used in the formwork are smooth and non-porous, reducing the chances of any texture or pattern transferring onto the concrete. This ensures a clean and uniform appearance of the finished concrete. In conclusion, steel frame formwork is essential for achieving a smooth concrete finish. It provides stability, precision, and minimizes the risk of formwork marks. Its strength, durability, and versatility make it an ideal choice for ensuring high-quality finishes in concrete construction projects.

- Q: Can steel frame formwork be used for both straight and sloped surfaces?

- Yes, steel frame formwork can be used for both straight and sloped surfaces. Steel frame formwork is highly versatile and can be easily adjusted to accommodate different surface angles and shapes. It allows for the construction of various structures, including walls, columns, beams, and slabs, in both horizontal and vertical orientations. The steel frame system provides strength, durability, and stability, making it suitable for a wide range of construction projects, regardless of whether the surface is straight or sloped. Additionally, steel frame formwork can be easily customized and modified to meet specific design requirements, allowing for flexibility in construction.

Send your message to us

Steel Fram Formworks Used for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords