Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

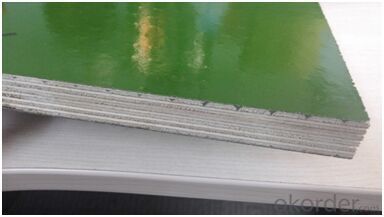

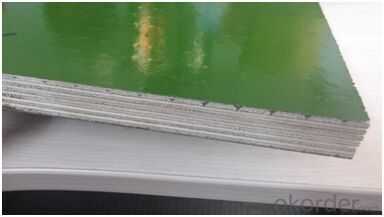

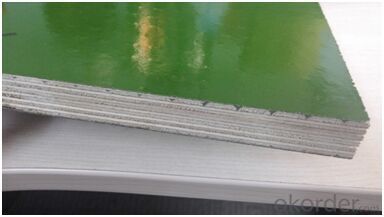

1. Structure of Light Steel Frame Formwork with Plastic Plywood

Light steel frame formwork is constructed with two different plywood as frames-wood plywood and plastic plywood. The light frame formwork with Plastic plywood more and more popular in construction industry.

2. Main Features of Light Steel Frame Formwork with Plastic Plywood

-High quality of plastic plywood can stay solid with more than 7 hours in boiled water.

-Frame of plywood is made of plastic as well

-Repeated use of more than 20 times

-PP material used

-Plywood is used inside

3. Light Steel Frame Formwork with Plastic plywood images

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork with Plastic plywood

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork with Plastic Plywood and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the different types of joints used in steel frame formwork?

- There are several types of joints used in steel frame formwork, each serving a specific purpose in the construction process. 1. Butt Joint: This is the most common type of joint used in steel frame formwork. It involves joining two steel members end to end, creating a flush and seamless connection. Butt joints are typically used in straight sections of the formwork where no angular changes are required. 2. Lap Joint: A lap joint is used when two steel members need to be connected side by side. One member overlaps the other, and the two are then welded or bolted together. This type of joint is commonly used in situations where additional strength and stability are needed, such as in corners or areas with high load-bearing requirements. 3. Corner Joint: As the name suggests, corner joints are used to connect steel members at corners or angles. These joints are designed to ensure a strong and stable connection, allowing the formwork to maintain its shape and withstand the forces exerted during the concrete pouring process. 4. T-Joint: T-joints are used to connect three steel members in a T-shape configuration. This type of joint is commonly used in situations where additional support or reinforcement is needed at specific points of the formwork system. 5. Splice Joint: Splice joints are used to connect two steel members end to end, similar to a butt joint. However, unlike butt joints, splice joints are typically used to connect longer sections of the formwork where a seamless connection is not necessary. Splice joints are often used in situations where ease of assembly and disassembly is important. Overall, the choice of joint used in steel frame formwork depends on the specific requirements of the construction project. Each type of joint offers its own advantages in terms of strength, stability, and ease of assembly, allowing the formwork system to be customized to meet the needs of the project.

- Q: Can steel frame formwork be used for energy-efficient and sustainable construction?

- Yes, steel frame formwork can be used for energy-efficient and sustainable construction. Steel is a highly durable material that can withstand extreme weather conditions and has a long lifespan, reducing the need for frequent replacements. Additionally, steel frame formwork can be easily recycled, reducing the environmental impact of construction. Its versatility allows for efficient insulation and thermal performance, contributing to energy efficiency. Overall, steel frame formwork is a viable option for sustainable and energy-efficient construction.

- Q: How does steel frame formwork handle concrete pouring in earthquake-prone areas?

- Steel frame formwork is designed to handle concrete pouring in earthquake-prone areas by providing a sturdy and robust structure. The steel frame provides excellent strength and stability, ensuring that the formwork can withstand the forces exerted during an earthquake. This helps to prevent any collapse or damage to the formwork during the pouring process, ensuring the concrete is properly contained and supported. Additionally, the steel frame formwork system can be reinforced with additional bracing or tie systems to further enhance its resistance to seismic activity. Overall, steel frame formwork is a reliable and safe option for concrete pouring in earthquake-prone areas.

- Q: What is the steel frame center support structure

- Steel structure and concrete structure, masonry structure, wood structure and so on, to the composition of the material structure.

- Q: How does steel frame formwork compare to timber formwork in terms of cost?

- In terms of cost, steel frame formwork generally tends to be more expensive compared to timber formwork. This is mainly due to the higher material and manufacturing costs associated with steel. Steel frame formwork requires the use of steel beams, panels, and other components, which are typically more expensive than timber materials. Additionally, constructing steel formwork requires specialized skills and equipment, which can further increase the overall cost. On the other hand, timber formwork is relatively more affordable as timber materials are generally cheaper and readily available. However, it is important to note that despite its initial higher cost, steel frame formwork offers several advantages that can contribute to cost savings in the long run. Steel formwork is more durable and has a longer lifespan compared to timber formwork, which can result in reduced maintenance and replacement costs over time. Moreover, the reusability of steel formwork is another cost-saving factor. Steel frames can be easily dismantled, transported, and reused for multiple construction projects, whereas timber formwork may need to be replaced after a few uses due to wear and tear. Ultimately, when considering the cost of formwork, it is essential to evaluate the specific needs and requirements of the project, as well as the expected lifespan and potential for reuse. While steel frame formwork may initially have a higher price tag, its durability and reusability can make it a more cost-effective choice in the long term, particularly for larger or repetitive projects. Conversely, timber formwork may be more suitable for smaller or one-time projects where cost efficiency is a primary concern.

- Q: How does steel frame formwork handle the placement of soundproofing and acoustical materials within the concrete structure?

- Steel frame formwork provides a sturdy and reliable support system for the placement of soundproofing and acoustical materials within a concrete structure. The steel framework ensures proper alignment and stability during the pouring and curing process, allowing for precise installation of these materials. Additionally, the steel frame formwork helps in minimizing any vibrations or noise transfer, enhancing the effectiveness of the soundproofing and acoustical measures.

- Q: How does steel frame formwork handle concrete pouring and curing processes?

- Steel frame formwork is a sturdy and reliable solution for concrete pouring and curing processes. Its rigid structure provides stability and support during the pouring stage, ensuring that the concrete is evenly distributed and does not leak or collapse. The steel frame formwork also allows for easy placement and adjustment of reinforcement bars, ensuring a strong and durable end result. During the curing process, the steel frame formwork helps retain the shape and integrity of the concrete, preventing any deformation or cracking. Overall, steel frame formwork offers excellent handling of concrete pouring and curing processes, leading to high-quality and long-lasting concrete structures.

- Q: Can steel frame formwork be used for retrofitting or renovation projects?

- Yes, steel frame formwork can be used for retrofitting or renovation projects. Its durable and versatile nature allows for easy modification and adaptation to existing structures, making it a suitable choice for such projects. Additionally, its strength and stability provide the necessary support for concrete pouring during renovation and retrofitting processes.

- Q: Can steel frame formwork be used in areas with limited site preparation?

- Areas with limited site preparation can effectively utilize steel frame formwork. This system is versatile and robust, easily accommodating different project requirements. Unlike traditional timber formwork, steel frame formwork does not necessitate extensive site preparation, such as ground leveling or compacting. The lightweight steel frames can be conveniently transported to the site, making them ideal for areas with limited access or challenging terrain. Moreover, the flexibility of steel frame formwork allows for easy adjustment to uneven surfaces or irregular shapes, which is particularly advantageous in areas where site preparation may be difficult. Additionally, steel frame formwork provides exceptional strength and durability, rendering it suitable for use in areas with limited site preparation. The steel frames are specifically designed to withstand heavy loads and offer stability to the formwork, ensuring the safety and efficiency of the construction process. In summary, steel frame formwork is a highly effective option in areas with limited site preparation due to its adaptability, versatility, and strength. Its ability to easily adjust to varying project requirements and withstand heavy loads makes it a suitable choice for diverse construction projects, regardless of site conditions.

- Q: How does steel frame formwork handle the placement of openings, such as windows and doors, within the concrete structure?

- Steel frame formwork is a highly versatile and flexible system that can easily handle the placement of openings, such as windows and doors, within a concrete structure. The steel frame formwork consists of modular panels that can be easily adjusted and customized according to the specific dimensions and requirements of the openings. Firstly, steel frame formwork allows for precise and accurate positioning of the openings. The modular panels can be easily adjusted and aligned to create the desired shape and size of the openings. This ensures that the windows and doors are placed in the exact location as per the architectural and structural drawings. Furthermore, the steel frame formwork provides sufficient structural support for the openings. The steel frames are sturdy and robust, capable of withstanding the pressure and weight of the concrete during the pouring and curing process. This ensures that the openings remain stable and intact, without any deformation or damage. Additionally, steel frame formwork enables the easy installation of door and window frames. The modular panels can be easily removed to create the necessary space for the installation of frames. The formwork also allows for the precise placement of anchor bolts or fasteners, ensuring a secure and stable connection between the frames and the concrete structure. Moreover, steel frame formwork allows for the integration of various accessories and components required for the openings, such as lintels, sills, and reveals. These can be easily incorporated into the formwork system, ensuring a seamless and professional finish for the openings. In conclusion, steel frame formwork offers a reliable and efficient solution for handling the placement of openings within a concrete structure. Its versatility, adjustability, and strength make it suitable for accommodating windows and doors of different sizes and shapes. The accurate positioning, structural support, and easy installation provided by steel frame formwork ensure that the openings are well-integrated into the overall concrete structure.

Send your message to us

Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords