Tabel Formwork for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

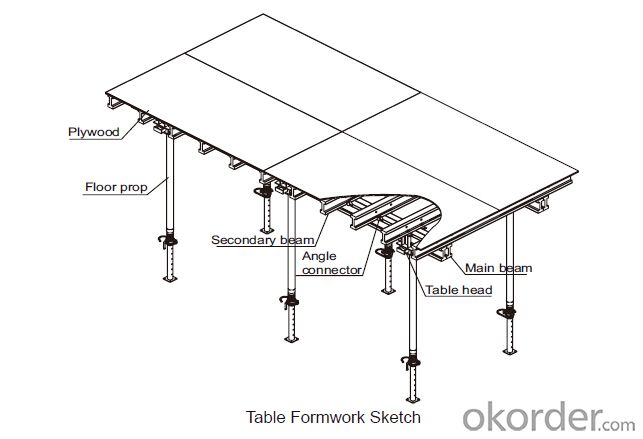

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel frame formwork be used for power plant structures?

- Certainly, power plant structures can utilize steel frame formwork. This construction method, which is both versatile and durable, proves suitable for various types of structures, including power plants. The robustness and rigidity of steel make it well-suited for withstanding the substantial loads and high temperatures typically associated with power plant structures. There are numerous advantages to employing steel frame formwork in power plant construction. Firstly, it guarantees exceptional structural integrity, ensuring the stability and safety of the power plant. Steel, being a robust material, can handle the weight and stress exerted by large power generation equipment and structures. Furthermore, steel frame formwork allows for design and construction flexibility. It can be easily tailored to accommodate the specific requirements of power plant structures, such as the necessity for spacious interiors, lofty ceilings, and intricate layouts. If there arises a need for future expansion or upgrades in the power plant, steel can be readily modified or expanded. Moreover, steel frame formwork enables faster construction times in comparison to traditional methods. The prefabricated nature of steel components facilitates swift and efficient assembly, thereby reducing construction time and costs. This holds particular significance in power plant projects, where timely completion is crucial to meet energy demands. In conclusion, due to its strength, durability, flexibility, and efficiency, steel frame formwork is undoubtedly suitable for power plant structures. It provides a reliable construction method for power plants, ensuring the safety, functionality, and longevity of these crucial infrastructure projects.

- Q: Can steel frame formwork be used for healthcare and medical facilities construction?

- Yes, steel frame formwork can be used for healthcare and medical facilities construction. Steel formwork offers durability and strength, making it suitable for withstanding the heavy usage and demanding requirements of healthcare facilities. Additionally, steel formwork can provide precise and accurate construction, ensuring the necessary quality standards and specifications are met in the construction of these critical facilities.

- Q: How is steel frame formwork assembled?

- Steel frame formwork is commonly used in construction projects for creating concrete walls, columns, beams, and slabs. The assembly process of steel frame formwork involves several steps. 1. Preparation: Before assembling the steel frame formwork, the construction site needs to be prepared. This includes leveling the ground, removing any debris, and setting up the necessary safety measures. 2. Layout and marking: The layout and dimensions of the concrete structure are marked on the ground or wall where the formwork will be installed. This ensures accurate placement of the steel frames. 3. Erecting vertical supports: Vertical supports are installed first to provide stability and strength to the formwork. These supports are usually made of steel or aluminum and are secured to the ground or wall using bolts or anchors. 4. Installing horizontal beams: Horizontal beams are connected to the vertical supports to create the frame structure. These beams are positioned according to the marked layout and are secured in place using connectors or clamps. 5. Attaching plywood panels: Plywood panels are then fixed to the steel frame using screws or nails. These panels act as the surface where the concrete will be poured and formed. The size and thickness of the plywood depend on the specific requirements of the project. 6. Reinforcement and bracing: Additional reinforcement and bracing are added to the formwork to ensure its stability during the concrete pouring process. This can include diagonal braces, tie rods, and cross beams that provide extra support and prevent any movement or deformation. 7. Finishing touches: Once the steel frame formwork is assembled, it is checked for any gaps, misalignments, or loose connections. These issues are rectified to ensure a tight and secure formwork structure. Any necessary adjustments or modifications are made at this stage. Overall, the assembly of steel frame formwork requires careful planning, accurate measurements, and proper installation techniques. It is essential to follow the manufacturer's instructions and adhere to safety guidelines to ensure a successful and safe construction process.

- Q: Can steel frame formwork be used in projects with limited project budget?

- Yes, steel frame formwork can be used in projects with a limited project budget. While steel frame formwork may require a higher initial investment compared to other formwork systems, it offers long-term cost savings due to its durability and reusability. Additionally, steel frame formwork provides high-quality finishes and greater dimensional accuracy, reducing the need for additional finishing work and potentially saving costs in the long run.

- Q: How does steel frame formwork handle different types of concrete additives?

- Steel frame formwork is highly versatile and can easily handle different types of concrete additives. The strength and rigidity of the steel frame provide excellent support and stability, allowing for the incorporation of various additives such as admixtures, fibers, or pigments into the concrete mixture. The steel frame formwork ensures that these additives are evenly distributed throughout the concrete, resulting in enhanced durability, improved workability, and improved aesthetic properties of the final structure.

- Q: Can steel frame formwork be used for prefabricated concrete elements?

- Certainly, prefabricated concrete elements can indeed utilize steel frame formwork. A highly adaptable and long-lasting system, steel frame formwork can effortlessly be modified and reutilized for a variety of concrete construction undertakings. By providing a rigid structure and precise alignment for concrete pouring, it guarantees the desired shape and dimensions of prefabricated elements. Furthermore, steel frame formwork grants greater design flexibility, enabling the accommodation of intricate shapes and structures. Its robustness and stability also render it suitable for withstanding the weight and pressure exerted by curing concrete. All in all, steel frame formwork presents a feasible choice for the creation of superior prefabricated concrete elements.

- Q: Can steel frame formwork be adjusted to different sizes and shapes?

- Yes, steel frame formwork can be easily adjusted to accommodate different sizes and shapes. Its modular design allows for flexibility and customization, making it suitable for various construction projects requiring different formwork dimensions and configurations.

- Q: How does steel frame formwork ensure the proper alignment and positioning of form ties?

- The form ties are held securely in place during the concrete pouring process with the help of the rigid and sturdy structure of the steel frame formwork. The steel frame acts as a guide and support system for the form ties, ensuring their proper alignment and positioning. Precision and accuracy are incorporated into the design of the steel frame, which includes predetermined positions for the form ties. These positions are typically marked or pre-drilled on the steel frame, making it easy and consistent to place the form ties. The form ties are inserted into the pre-determined positions of the steel frame, where they are held securely by the frame's strong clamping mechanism. This mechanism prevents any movement or displacement of the form ties while the concrete is being poured. In addition, the steel frame's rigid nature ensures that it remains stable and maintains its shape, even under the pressure exerted by the wet concrete. This stability is crucial for the proper alignment and positioning of the form ties, as any misalignment or movement can result in uneven concrete surfaces or structural weaknesses. In conclusion, steel frame formwork offers a reliable and efficient solution for ensuring the proper alignment and positioning of form ties. Its robust and stable structure, along with its predetermined positions and secure clamping mechanism, guarantees accurate and consistent placement of form ties, resulting in high-quality concrete structures.

- Q: How does steel frame formwork ensure proper anchoring to the ground?

- Steel frame formwork ensures proper anchoring to the ground through a combination of factors. Firstly, the steel frame itself is designed with sturdy anchor points and connection mechanisms that help secure it firmly to the ground. Additionally, the formwork is often supported by vertical supports such as props or scaffolding, which further enhance its stability and prevent any movement. This ensures that the formwork remains in place during the concrete pouring and curing process, ultimately resulting in a properly anchored structure.

- Q: How does steel frame formwork contribute to better concrete compaction?

- There are several ways in which steel frame formwork enhances concrete compaction. To begin with, the inflexible and robust nature of steel frame formwork offers a stable and sturdy support system for the concrete during pouring and compaction. This guarantees that the concrete maintains its desired shape and position, preventing any deformity or displacement that could compromise its strength and durability. Furthermore, steel frame formwork is designed with precision and accuracy, allowing for accurate alignment and leveling of the formwork. This results in even and uniform pouring of the concrete, facilitating improved compaction. Inconsistent pouring can lead to irregularities in the density and strength of the concrete, potentially causing structural problems in the future. Moreover, steel frame formwork often incorporates adjustable features like telescopic struts or clamps, which enable tight and secure fastening of the formwork. This minimizes any movement or vibration of the formwork during the compaction process, leading to better consolidation of the concrete. Adequate consolidation is crucial in eliminating air voids and excess water from the concrete, resulting in a denser and more durable final product. Additionally, steel frame formwork typically possesses smooth surfaces and clean edges, which allows for effortless removal of the formwork once the concrete has set. This smoothness helps prevent any drag or drag marks during the removal process, which could adversely affect the quality of the compaction. In conclusion, steel frame formwork enhances concrete compaction by providing a stable and sturdy support structure, ensuring accurate alignment and leveling, facilitating tight and secure fastening, and allowing for easy removal without compromising the quality of the compaction.

Send your message to us

Tabel Formwork for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords