Tabel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

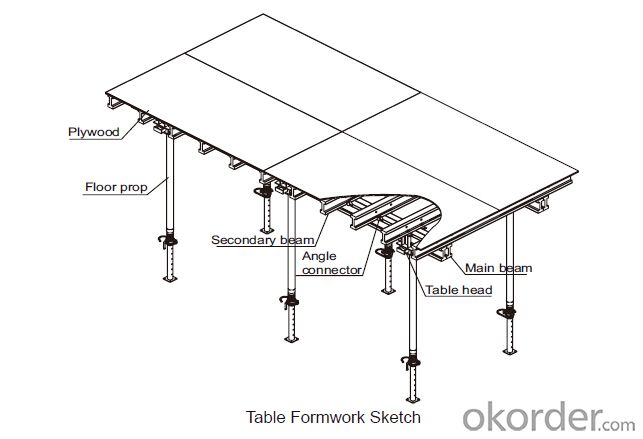

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel frame formwork be used for both straight and curved slabs?

- Yes, steel frame formwork can be used for both straight and curved slabs. Steel frame formwork is a versatile and flexible system that can be easily adjusted to accommodate different shapes and sizes of slabs. The steel frames can be easily curved or bent to match the desired shape of the slab. This makes it suitable for creating both straight and curved slabs, providing the necessary support and stability during the concrete pouring process. Additionally, steel frame formwork offers the advantage of being reusable, making it a cost-effective solution for various construction projects.

- Q: What are the different types of formwork shoes used in steel frame formwork systems?

- Steel frame formwork systems utilize various types of formwork shoes for different purposes. Some commonly used types include adjustable screw jacks, flat steel shoes, U-head shoes, base plates, and castor shoes. Adjustable screw jacks, typically made of steel, allow for easy height adjustment and leveling of the formwork system. They provide support and stability. Flat steel shoes, consisting of flat steel plates, serve as a stable base for the formwork system. They are placed under the vertical members to evenly distribute the load and prevent sinking or tilting. U-head shoes, designed in a U shape, support horizontal beams or joists in the formwork system. They work alongside adjustable screw jacks to enhance support and stability. Base plates, made of steel, establish a solid foundation for the formwork system. They are placed directly on the ground or a concrete slab to support the vertical members. Castor shoes, equipped with castor wheels, enable mobility in the formwork system. They allow for easy movement and can be locked to ensure stability during construction. Choosing the appropriate formwork shoes depends on project-specific requirements, such as load-bearing capacity, height adjustment needs, and mobility requirements. It is crucial to select the right type to ensure the stability and safety of the steel frame formwork system.

- Q: Is the bamboo plywood and wood plywood the same?

- Because of the high hardness of bamboo, with fixed drill drilling needs. Therefore, wood template is more simple and convenient. Hope to help you.

- Q: Can steel frame formwork be used for decorative concrete structures?

- Yes, steel frame formwork can be used for decorative concrete structures. Steel frame formwork provides strength and stability, making it suitable for creating intricate and complex designs in decorative concrete structures. Its versatility allows for various shapes and patterns to be achieved, enhancing the aesthetic appeal of the final product.

- Q: What are the different types of edge protection systems used with steel frame formwork?

- There are several types of edge protection systems commonly used with steel frame formwork. These include guardrails, toe boards, and safety nets. Guardrails are horizontal barriers that provide a physical barrier along the edges of the formwork to prevent falls. Toe boards are vertical barriers installed at the base of the formwork to prevent tools and materials from falling off the edges. Safety nets are installed below the formwork to catch any falling objects and prevent them from reaching the ground. These edge protection systems are essential for ensuring the safety of workers and preventing accidents on construction sites.

- Q: ANSYS steel frame structure modeling, commonly used in size, density, Poisson's ratio is much better? Help。

- Such as the large cross-section of channel steel, I-beam, density 7.85x10^3/m^3

- Q: What are the transportation and storage requirements for steel frame formwork?

- The transportation and storage requirements for steel frame formwork are relatively straightforward. In terms of transportation, steel frame formwork is typically transported using trucks or trailers. Due to the weight of the steel frames, it is important to ensure that the vehicles used for transportation are capable of handling the load. The frames should be securely fastened to the vehicle to prevent any movement or damage during transit. As for storage, steel frame formwork should be stored in a dry and well-ventilated area to prevent rust or corrosion. Ideally, the frames should be stored indoors to protect them from the elements. If indoor storage is not possible, the frames should be covered with a waterproof tarp or sheeting to protect them from rain or snow. Additionally, it is important to stack the frames properly to avoid any deformation or damage. The frames should be stacked in a stable manner, with larger and heavier frames on the bottom and smaller frames on top. It is also recommended to place wooden spacers between the frames to prevent any direct contact and potential scratches. Regular maintenance and inspection of the steel frame formwork is also crucial to ensure its longevity and safety. This includes checking for any signs of damage, such as bent or cracked frames, and promptly addressing any issues that arise. Overall, proper transportation and storage of steel frame formwork is essential to protect the frames from damage and ensure their longevity, which in turn contributes to the efficiency and safety of construction projects.

- Q: Can steel frame formwork be used for concrete stairs?

- Concrete stairs can indeed be constructed using steel frame formwork. This system, known for its versatility and durability, can be tailored to meet different construction requirements, including the creation of stairs. It boasts numerous benefits, such as exceptional strength, stability, and the capability to fashion intricate patterns and designs. By employing steel frame formwork, one can achieve a dependable and efficient approach to building concrete stairs, resulting in a sturdy and enduring structure.

- Q: What is the difference between the wheel steel frame and the aluminum frame

- 5 strength, steel has obvious advantages, aluminum alloy is relatively soft, easy to deformation, not easy to repair;6 energy saving, aluminum alloy oil, steel slightly worse;In the selection, if the vehicle is heavy work load, or steel wheels, if only the household vehicle needs beautiful point, you can choose Aluminum Alloy hub.

- Q: Can steel frame formwork be used for both monolithic and composite concrete structures?

- Steel frame formwork is suitable for both monolithic and composite concrete structures. This adaptable formwork system can be customized to fit various types of concrete structures. When constructing monolithic structures, the steel frame formwork acts as a temporary mold or framework. It supports the wet concrete until it cures and gains enough strength to support itself. This formwork system is commonly utilized in building walls, columns, and slabs, among other structures. In composite structures, the steel frame formwork is also employed, but with an added layer of reinforcement embedded within the concrete, such as steel bars or mesh. This reinforcement enhances the structure's strength and durability. Composite structures are frequently found in bridges, high-rise buildings, and other heavy-duty applications where increased load-bearing capacity is necessary. Using steel frame formwork offers numerous advantages for both monolithic and composite structures. It provides a sturdy and rigid support system during construction, ensuring precise and accurate concrete placement. Moreover, steel formwork is highly durable and can be reused multiple times, making it a cost-effective choice. Additionally, its modular design facilitates easy assembly and disassembly, saving time and labor on-site. In conclusion, steel frame formwork is a dependable and versatile solution for successful construction projects involving both monolithic and composite concrete structures. It provides the essential support and strength required for the completion of such projects.

Send your message to us

Tabel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords