Steel Frame Formworks in China Market for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

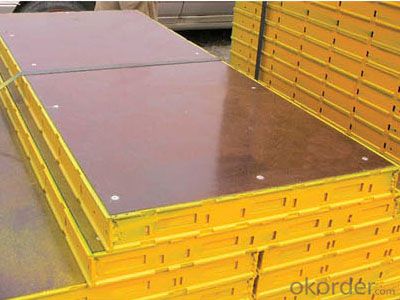

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Steel frame wood fire doors and steel doors is a concept

- Steel wood fire doors that wood fire doors. The door is made of double layer board, which is coated with a galvanized iron sheet or a double layer wood board with a single side of a gypsum board, and a double layer board and a double layer of asbestos can be used. The new standard fire door fire door provisions of steel wood burning wood or difficult burning wood products making door frame and door frame, door panel, door fire insulation materials filling material is non-toxic and harmless to the human body and steel, and with fire hardware fittings with certain refractory properties of the door. The fire resistance of the fire doors are above 1.2H.

- Q: How does steel frame formwork accommodate for different concrete surface finishes?

- The versatility of steel frame formwork allows for easy accommodation of different concrete surface finishes. One of the main advantages of this system is its flexibility in creating various surface textures and finishes. To achieve different finishes, customization of the steel frame formwork is possible by utilizing different types of form liners, textures, or surface treatments. Form liners are commonly utilized to create patterns or textures on the concrete surface. These liners are made from various materials, such as rubber, plastic, or fiberglass, and can be easily attached to the steel formwork. For a smooth finish, smooth form liners can be utilized to line the steel formwork, allowing for the concrete to set with a flat and uniform surface. Conversely, if a textured or patterned finish is desired, specific design form liners can be used. These liners can create various textures, including brick patterns, wood grains, or unique designs. Aside from form liners, other surface treatments can also be applied to the steel formwork to enhance the concrete surface finish. These treatments may involve the application of release agents, chemical retarders, or pigments to achieve specific effects. Release agents aid in preventing the concrete from adhering to the formwork, thus allowing for easy removal and a smooth finish. Chemical retarders can be employed to slow down the setting time of the concrete, which is advantageous for achieving exposed aggregate or textured finishes. Pigments can be added to the concrete mix to introduce color and create visually appealing surfaces. In summary, steel frame formwork offers a flexible platform for achieving a variety of concrete surface finishes. Through the utilization of different form liners, textures, and surface treatments, the steel formwork can be customized to meet specific finish requirements. This versatility makes steel frame formwork an ideal choice for projects that require diverse surface finishes.

- Q: Can steel frame formwork be used in projects with limited formwork storage space?

- Yes, steel frame formwork can be used in projects with limited formwork storage space. Steel frame formwork is known for its versatility and compactness, making it an ideal choice for projects with limited storage space. Unlike traditional timber formwork, steel frame formwork is designed to be lightweight and easy to handle, allowing for efficient storage and transportation. Additionally, steel frame formwork offers the advantage of being reusable, which further reduces the need for additional storage space. The modular nature of steel frame formwork allows for easy assembly and disassembly, enabling the formwork to be quickly stored away when not in use. Furthermore, steel frame formwork provides excellent strength and durability, ensuring a long lifespan and minimizing the need for frequent replacements. This reduces the overall amount of formwork material required, thus optimizing storage space. In conclusion, steel frame formwork is a suitable choice for projects with limited formwork storage space due to its compactness, reusability, and durability. Its lightweight and modular design make it easy to handle and store, allowing for efficient use of available space.

- Q: Can steel frame formwork be used for both interior and exterior concrete structures?

- Steel frame formwork is suitable for both interior and exterior concrete structures. Its versatility allows for customization to meet the specific needs of different construction projects. This formwork system provides a robust and long-lasting support system for pouring concrete, able to withstand the pressures exerted during the curing process. Whether it is for interior walls, columns, or exterior structures like beams and slabs, steel frame formwork can be easily adjusted and installed. Its popularity in construction projects of various scales is due to its flexibility, strength, and stability.

- Q: Do steel frame formwork systems require any additional support or reinforcement?

- It is common for steel frame formwork systems to require extra support or reinforcement in different construction projects. While these systems are generally strong and sturdy, they may need additional support to handle larger concrete loads or ensure stability during construction. There are various ways to provide this extra support or reinforcement. For instance, diagonal bracing can be used to strengthen the steel frame and prevent any potential deformation or collapse. Steel props or shoring systems may also be necessary to provide additional support to the formwork, especially when dealing with high concrete loads or large distances. In some cases, engineers may recommend using tie rods, walers, or other structural elements to reinforce the steel frame formwork system. These elements help evenly distribute the loads and provide the necessary stability during concrete pouring and curing. Ultimately, the need for additional support or reinforcement depends on specific project requirements, such as the size and complexity of the structure, the concrete loads involved, and the safety standards. It is vital to consult with a qualified structural engineer or construction professional to determine the appropriate level of support or reinforcement needed for a steel frame formwork system.

- Q: Are there any safety considerations associated with steel frame formwork?

- There are various safety considerations related to steel frame formwork. Firstly, the weight of the formwork necessitates proper handling and lifting techniques to prevent musculoskeletal injuries. Workers should be adequately trained in using lifting equipment and techniques to avoid strains and sprains. Moreover, working at height is often required when using steel frame formwork, which poses fall hazards. To prevent falls and protect workers from serious injuries or fatalities, it is crucial to implement appropriate fall protection measures such as safety harnesses, guardrails, and safety nets. Another factor to consider is the stability of the steel frame formwork. It is vital to ensure that the formwork is adequately braced and secured to prevent collapse or movement during concrete pouring and curing. Regular inspections should be carried out to identify and address any potential stability issues. Furthermore, steel formwork can be susceptible to corrosion if not properly maintained. Rust and corrosion can weaken the structure and compromise safety. To maintain the integrity and safety of the steel frame formwork, regular inspections and maintenance activities such as cleaning, painting, and applying anti-corrosion treatments are necessary. Lastly, effective communication and coordination among workers are essential to prevent accidents and injuries. Clear instructions, safety briefings, and established communication channels are necessary to ensure that everyone understands their roles and responsibilities and can work together safely. In conclusion, while steel frame formwork offers numerous benefits, it is crucial to be mindful of and address the safety considerations associated with its use. This is essential to protect workers and maintain a safe working environment.

- Q: Can steel frame formwork be easily repaired or modified on-site?

- On-site repairs or modifications to steel frame formwork are easily achievable. Steel, being both durable and strong, can withstand heavy loads and harsh conditions. Should any damage occur or modifications be necessary, it is simple to replace or alter the affected or unwanted portions. Typically, the steel frame formwork system consists of modular components that can be easily disassembled and reassembled as required. This flexibility allows for straightforward on-site repairs or modifications without the need for extensive construction. Furthermore, the use of standardized components in steel frame formwork simplifies the process of finding replacement parts if necessary. All in all, the repair or modification of steel frame formwork on-site is a relatively uncomplicated and direct procedure.

- Q: How does steel frame formwork accommodate for different concrete pouring techniques?

- Steel frame formwork is a versatile and adaptable system that can accommodate different concrete pouring techniques. The design of steel frame formwork allows for various customization options, making it suitable for a wide range of construction projects. One way in which steel frame formwork accommodates different concrete pouring techniques is through its adjustable panels and modular components. These panels can be easily repositioned and adjusted to create different shapes and sizes, allowing for flexibility in the pouring technique. Whether it is a simple straight wall or a complex curved structure, the steel frame formwork can be adjusted accordingly to accommodate the desired concrete pouring technique. Additionally, the steel frame formwork system often includes various accessories and attachments that can be used to further customize the pouring technique. This may include adjustable supports, tie rods, and clamps, among others. These accessories provide additional stability and reinforcement to the formwork, ensuring that it can withstand the pressure and weight of the concrete during pouring. Furthermore, steel frame formwork is known for its high load-bearing capacity and durability. This allows for different pouring techniques, such as high-density concrete or rapid pouring, to be accommodated without compromising the integrity of the formwork system. The strength and stability of the steel frame formwork ensure that it can handle the increased pressure and weight associated with different pouring techniques. In summary, steel frame formwork accommodates different concrete pouring techniques through its adjustable panels, modular components, accessories, and high load-bearing capacity. This versatility allows for customization and adaptability, making it a preferred choice for construction projects that require flexibility in the pouring technique.

- Q: Does steel frame formwork require any specific maintenance?

- Yes, steel frame formwork does require specific maintenance. Regular cleaning and inspection of the formwork is necessary to ensure its structural integrity. Any rust or corrosion should be addressed promptly to prevent further damage. Additionally, lubrication of moving parts and proper storage when not in use can help prolong the lifespan of the steel frame formwork.

- Q: How does steel frame formwork handle the placement of openings, such as windows and doors, within the concrete structure?

- Steel frame formwork handles the placement of openings, such as windows and doors, within the concrete structure by providing pre-designed and pre-fabricated panels that can be easily adjusted to accommodate the desired opening sizes and locations. These panels are designed with the necessary reinforcements and supports to ensure the stability and structural integrity of the concrete structure, while also allowing for precise and efficient installation of windows and doors during the construction process.

Send your message to us

Steel Frame Formworks in China Market for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches