Custom High Security H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

pouring straight wall

Concrete Wall Formwork

Waterproof Wall Formwork

retaining wall formwork

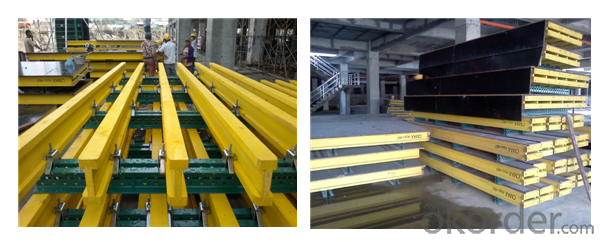

Custom High Security H20 Timber Beam Formwork for Straight Concrete Wall

Description:

1. Structure sketch

TBW system-A is a kind of formwork for pouring straight wall, it is composed of several pieces of Tim-formwork, yoke, tie rod, wing nut, etc.

It will be designed according to wall’s size.

Competitive Advantage:

1. Prefabricated connection, convenient and efficient.

2. Light weight but high bearing capacity.

For conventional design, its load bearing capacity is 60KN/m2 with weight of 55-60kg/m2.

If required, the formwork can be specially designed for higher concrete pressures.

3. Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

Applications:

- Q: How does steel frame formwork support the construction of slabs and beams?

- The construction of slabs and beams is supported by steel frame formwork, which creates a stable and rigid structure to contain and shape the concrete during pouring and curing. To begin, the desired dimensions and layout of the slab or beam determine how the steel frame formwork is assembled. Sturdy steel sections are typically used to construct frames that are bolted or welded together, resulting in a strong and durable framework. This framework is designed to withstand the pressure and weight of the concrete while maintaining its shape and position. Once the formwork is in place, it is carefully aligned and secured to the ground or supporting structure to prevent any movement or displacement during concrete pouring. This alignment and security are critical to ensure accurate construction that meets the required specifications. Steel frame formwork also incorporates various support systems, such as adjustable props or scaffolding, to provide additional strength and stability. These supports evenly distribute the weight of the concrete across the formwork, preventing excessive load or stress on specific areas. This ensures that the slab or beam is uniformly reinforced and structurally sound. Moreover, steel frame formwork allows for the creation of complex shapes and designs, including curved or inclined surfaces. It can be easily adjusted or modified to accommodate different architectural requirements, offering flexibility and creativity in the construction process. In summary, steel frame formwork is essential in supporting the construction of slabs and beams by providing a robust and reliable structure to contain the concrete. It ensures accuracy, strength, and stability, ultimately contributing to the successful completion of a high-quality and safe construction project.

- Q: How does steel frame formwork handle the placement of façade elements and architectural features within the concrete structure?

- A versatile and efficient method for handling the placement of façade elements and architectural features within a concrete structure is steel frame formwork. This system consists of pre-engineered steel frames that can be easily assembled and disassembled. When it comes to placing façade elements like windows, doors, and cladding, steel frame formwork offers a sturdy and reliable support system. The frames are designed to withstand the weight and pressure of these elements during the concrete pouring process, ensuring their proper positioning without displacement or damage. Steel frame formwork also accommodates architectural features, such as decorative panels, cornices, and intricate designs, with ease. The frames can be customized to match the desired shape, size, and contours of these features, allowing for precise and accurate placement within the concrete structure. Additionally, steel frame formwork allows for flexibility in terms of adjustments and modifications. As the frames are easily assembled and disassembled, any changes or alterations to the placement of façade elements or architectural features can be accommodated effortlessly. This ensures that the final concrete structure meets the design requirements and architectural vision. Apart from its handling capabilities, steel frame formwork offers other benefits such as durability, reusability, and cost-effectiveness. The steel frames can withstand multiple uses, reducing the need for frequent replacements. This saves time, money, and promotes sustainable construction practices by minimizing waste. In conclusion, steel frame formwork is the ideal solution for handling the placement of façade elements and architectural features within a concrete structure. Its strength, flexibility, and efficiency make it the preferred choice for construction projects that require precise and reliable positioning of these elements.

- Q: What is the typical lifespan of steel frame formwork accessories?

- The typical lifespan of steel frame formwork accessories can vary depending on various factors such as usage, maintenance, and quality of the materials. However, with proper care and regular maintenance, steel frame formwork accessories can last for many years, often exceeding 10 to 15 years or more.

- Q: Can steel frame formwork be used in projects with high traffic or heavy loads?

- Indeed, steel frame formwork is perfectly suitable for projects characterized by heavy traffic or substantial loads. Renowned for its durability, strength, and stability, steel frame formwork emerges as a dependable option for such endeavors. Its sturdy build enables it to endure significant loads and frequent usage without jeopardizing its structural integrity. Moreover, steel frame formwork offers exceptional support and stability, guaranteeing the safety of both workers and the structure itself. Its capacity to withstand high traffic or heavy loads renders it a favored selection in diverse construction undertakings, encompassing bridges, tall buildings, and infrastructure ventures.

- Q: How does steel frame formwork affect the overall maintenance requirements of a structure?

- Steel frame formwork can have a significant impact on the overall maintenance requirements of a structure. Firstly, the use of steel frame formwork provides a durable and robust support system for concrete during the construction process. This ensures that the structure is built to the highest standards, reducing the likelihood of maintenance issues arising from poor construction techniques. Additionally, steel frame formwork is designed to be reusable, which can greatly reduce the maintenance requirements of a structure over its lifespan. Unlike traditional timber formwork, steel frames are less prone to damage, warping, or rotting. This means that they can be easily cleaned, repaired, and reused for multiple construction projects, resulting in cost savings and reduced waste. Furthermore, the use of steel frame formwork allows for faster construction times, which can also contribute to lower maintenance requirements. With shorter construction periods, there is less exposure to adverse weather conditions and potential damage. This can help to minimize the need for maintenance and repairs in the long run. Moreover, the strength and stability provided by steel frame formwork can enhance the structural integrity of the building, reducing the risk of structural failures or issues that may require ongoing maintenance. This ensures that the structure remains safe and secure for its occupants. In conclusion, steel frame formwork can positively impact the overall maintenance requirements of a structure by providing a durable, reusable, and efficient construction method. By reducing the potential for construction-related issues and improving structural integrity, steel frame formwork can help minimize the need for ongoing maintenance, resulting in a more cost-effective and sustainable solution.

- Q: What are the different types of support systems used with steel frame formwork?

- There are several different types of support systems that can be used with steel frame formwork in construction projects. These support systems are designed to provide stability and strength to the formwork, ensuring that it can withstand the weight and pressure of the concrete being poured. One common type of support system used with steel frame formwork is adjustable steel props. These props are adjustable in height and can be easily positioned to support the formwork at the desired level. They are typically used in conjunction with horizontal beams to provide additional support. Another type of support system is horizontal beams, also known as walers. These beams are typically made of steel or aluminum and are used to distribute the weight of the formwork across a larger area. They are placed horizontally and are secured to the vertical supports or props, providing additional stability to the formwork. In addition to adjustable props and horizontal beams, diagonal or cross-bracing can also be used as a support system. These diagonal members are typically made of steel and are used to provide additional rigidity and stability to the formwork. They are installed diagonally between the vertical supports or props, creating a triangular structure that helps to prevent the formwork from collapsing or deforming under the weight of the concrete. Finally, tie rods or tie wires can also be used as a support system for steel frame formwork. These rods or wires are used to secure the formwork panels together, creating a tight and rigid structure. They are typically placed at regular intervals along the formwork panels and are tightened to provide additional support and stability. Overall, the different types of support systems used with steel frame formwork are adjustable steel props, horizontal beams, diagonal or cross-bracing, and tie rods or tie wires. Each of these support systems plays a crucial role in ensuring the strength and stability of the formwork during the concrete pouring process.

- Q: Can steel frame formwork be used for both precast and cast-in-place concrete walls?

- Yes, steel frame formwork can be used for both precast and cast-in-place concrete walls. Steel frame formwork is a versatile and durable system that can be easily assembled and disassembled, making it suitable for various construction processes. For precast concrete walls, the steel frame formwork can be used to create the mold or form for the concrete panel, which is then cast and cured off-site before being transported and installed. In the case of cast-in-place concrete walls, the steel frame formwork is used on-site to create the formwork for the concrete wall, which is poured and cured in place. This flexibility of steel frame formwork allows it to be used in both precast and cast-in-place applications, providing efficient and reliable results for different construction needs.

- Q: How does steel frame formwork contribute to the overall sustainability of the built environment?

- Steel frame formwork plays a significant role in enhancing the sustainability of the built environment in various ways. To begin with, steel possesses exceptional durability, ensuring that steel frame formwork can be reused multiple times for different construction projects. This reduces the demand for new formwork materials and minimizes waste production. Furthermore, steel frame formwork offers versatility and adaptability, allowing for easy adjustments and modifications to meet changing design or construction requirements. This flexibility reduces the need for additional resources and materials, leading to resource efficiency and a decreased environmental impact during the construction process. Additionally, steel is a recyclable material, meaning that at the end of its life cycle, the steel frame formwork can be recycled and used to manufacture new steel products. This conservation of natural resources also helps reduce the energy consumption and emissions associated with the production of virgin materials. Moreover, steel frame formwork provides superior precision and structural stability, resulting in efficient and robust construction. This minimizes the occurrence of errors and failures during the construction process, leading to reduced waste of materials and resources. The improved construction quality also enhances the durability and performance of the built environment, reducing the need for future repairs and replacements. Lastly, steel frame formwork contributes to the energy efficiency of buildings. The lightweight nature of steel enables the construction of thinner and more thermally efficient walls, reducing energy consumption for heating and cooling. This leads to lower carbon emissions and decreased energy costs throughout the lifespan of the building. In conclusion, the incorporation of steel frame formwork in construction projects significantly enhances the overall sustainability of the built environment. Its durability, reusability, recyclability, flexibility, and energy efficiency contribute to minimizing waste, conserving resources, reducing environmental impacts, and creating resilient, efficient, and long-lasting buildings.

- Q: Can steel frame formwork be used for suspended slabs?

- Yes, steel frame formwork can be used for suspended slabs.

- Q: What are the safety precautions to be followed while using steel frame formwork?

- When using steel frame formwork, there are several important safety precautions that should be followed to ensure the well-being of workers and the successful completion of the construction project. These precautions include: 1. Training: All workers involved in using steel frame formwork should receive proper training on its assembly, use, and disassembly. This training should cover safe handling practices, proper installation techniques, and how to identify and address potential hazards. 2. Inspection: Before using steel frame formwork, it is crucial to inspect the equipment thoroughly for any damage or defects. Any damaged or faulty parts should be replaced or repaired before use to prevent accidents or structural failures. 3. Personal Protective Equipment (PPE): Workers should wear appropriate PPE, such as hard hats, safety goggles, gloves, and steel-toed boots, to protect themselves from potential falling objects, debris, and other hazards that may arise during the use of steel frame formwork. 4. Fall Protection: Adequate fall protection systems, such as guardrails, safety nets, or personal fall arrest systems, should be in place to prevent workers from falling from heights while assembling or disassembling steel frame formwork. 5. Stability and Secure Placement: Steel frame formwork should be securely placed and supported to ensure stability during use. This includes ensuring proper footing and bracing of the formwork to prevent collapse or movement during concrete pouring or other construction activities. 6. Load Capacity: It is essential to consider and adhere to the load capacity limits of the steel frame formwork. Exceeding these limits can lead to structural failures and accidents. Proper calculations should be done to determine the maximum load capacity and ensure it is not exceeded. 7. Communication and Coordination: Clear communication and coordination between all workers involved in using steel frame formwork are crucial. This includes regular meetings, clear instructions, and a designated supervisor overseeing the work to ensure that safety protocols are followed. 8. Regular Inspections: Regular inspections should be conducted throughout the use of steel frame formwork to identify any potential hazards or issues that may arise. Any problems should be addressed immediately to prevent accidents or disruptions in the construction process. By following these safety precautions, workers can minimize the risk of accidents, injuries, and structural failures while using steel frame formwork.

Send your message to us

Custom High Security H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches