Adjustable H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Light weight,

high bearing capacity,

adjustable column walers

Adjustable H20 Timber Beam Formwork For Rectangle Concrete Column Formwork

Description:

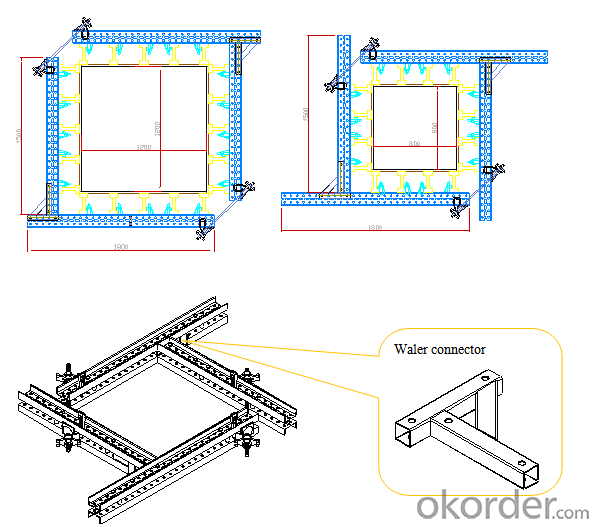

1. Structure sketch

TBC system-B is a kind of formwork for pouring square or rectangle column, it is composed of four pieces of Tim-formwork, yoke, tie rod, wing nut, etc.

It will be designed according to column’s size; the formwork’s dimension is adjustable.

Competitive Advantage:

1. Prefabricated connection, convenient and efficient.

2. Light weight but high bearing capacity.

For conventional design, its load bearing capacity is 80KN/m2 with weight of 55-65kg/m2.

If required, the formwork can be specially designed for high concrete pressures.

3. Adjustable cross-sections with adjustable column walers.

The column formwork for forming various cross-section and height. With the TBC-B, square or rectangular cross-sections up to 80 x 120 cm can be concreted – the formwork is continuous adjustable.

Applications:

- Q: Can steel frame formwork be used for foundations?

- Foundations can indeed utilize steel frame formwork. This particular system is known for its versatility and durability, as it can easily adapt to various foundation shapes and sizes. By providing a solid and sturdy framework, it enables the precise and accurate construction of foundation structures through the pouring of concrete. Steel frame formwork proves especially valuable in larger construction projects, where efficiency, strength, and speed are crucial considerations. Moreover, its reusability makes it a cost-effective choice for foundation construction. Nonetheless, it is vital to ensure that the steel frame formwork is expertly designed and installed to withstand the pressures and loads exerted during the concrete pouring process.

- Q: What are the different types of formwork leveling systems used with steel frame formwork?

- Steel frame formwork commonly utilizes various types of formwork leveling systems to ensure proper alignment and levelness, which is crucial for achieving high-quality concrete finishes. One commonly used leveling system for steel frame formwork is the adjustable leveling jack. These jacks, made of steel, feature a threaded rod that allows for easy adjustment to raise or lower the formwork as needed. They offer precise control over leveling and are user-friendly. Another leveling system is the leveling wedge, typically made of steel or plastic. These wedges are placed between the formwork and the supporting structure to guarantee levelness. They are effective, simple to use, and can be easily adjusted to achieve the desired level. For large-scale construction projects demanding accurate leveling, hydraulic jacks are utilized in certain formwork leveling systems. These jacks are adjustable and provide a high level of accuracy. Furthermore, specialized leveling accessories like leveling plates and leveling screws can be employed in conjunction with steel frame formwork. These accessories offer additional support and precise leveling control, particularly in areas with uneven or unstable ground conditions. Ultimately, the selection of a formwork leveling system depends on the specific requirements of the construction project. Factors such as the size and complexity of the structure, desired levelness, and available budget will all influence the choice of the most suitable system.

- Q: How does steel frame formwork handle different types of cured concrete removal techniques?

- Steel frame formwork is a versatile system that is designed to handle different types of cured concrete removal techniques effectively. The strength and durability of the steel frame enable it to withstand the forces generated during the removal process. One common technique used for concrete removal is mechanical chipping or breaking. In this method, a pneumatic or hydraulic breaker is used to chip away at the concrete surface. The steel frame formwork provides a stable and rigid platform for the operator to work on, ensuring precise and controlled removal of the concrete. The steel frame also acts as a barrier, protecting the surrounding areas from damage. Another technique used for concrete removal is hydro demolition, which involves using high-pressure water jets to break down the concrete. Steel frame formwork can handle this technique as it is resistant to water and can withstand the high-pressure water jets without being damaged. The steel frame's structural integrity remains intact, providing a safe and efficient removal process. Additionally, in some cases, chemicals or acids may be used to dissolve or soften the concrete for removal. Steel frame formwork is resistant to corrosion, making it suitable for such techniques. The steel frame can handle the exposure to chemicals without deteriorating, ensuring a long-lasting and reliable formwork system. Furthermore, steel frame formwork can also accommodate thermal techniques for concrete removal. For instance, the application of heat using torches or flame guns can be used to break down the concrete. The steel frame's heat resistance allows it to withstand the high temperatures without warping or deforming. Overall, steel frame formwork is well-equipped to handle different types of cured concrete removal techniques. Its strength, durability, resistance to water and chemicals, and heat resistance make it a reliable choice for construction projects where concrete removal is required.

- Q: Can steel frame formwork be used for curved or circular structures?

- Curved or circular structures can indeed be constructed using steel frame formwork. The flexibility of steel formwork allows for easy shaping to match the desired curve or shape of the structure. The steel frames can be modified and adjusted to achieve the desired form, guaranteeing accuracy and precision. This adaptability enables the construction of complex and unique curved or circular structures effortlessly. Furthermore, steel's strength and durability make it an excellent option for formwork, ensuring its ability to withstand the pressures and forces exerted during construction. In conclusion, steel frame formwork is a dependable and versatile solution for forming curved or circular structures.

- Q: How does steel frame formwork address issues of concrete cracking and spalling?

- Steel frame formwork addresses issues of concrete cracking and spalling by providing a strong and stable support system for the concrete during the pouring and curing process. The steel frame ensures that the concrete is properly contained and supported, reducing the likelihood of cracking and spalling. Additionally, the steel frame formwork allows for a more uniform distribution of forces, minimizing stress concentrations that could lead to cracking.

- Q: How does steel frame formwork handle architectural features such as openings and recesses?

- Steel frame formwork is a versatile construction technique that is well-equipped to handle architectural features such as openings and recesses. One of the key advantages of steel frame formwork is its flexibility in accommodating various shapes and sizes. When it comes to openings, such as doors and windows, steel frame formwork can easily incorporate these architectural features into the structure. The steel frames can be modified or adjusted to match the dimensions of the openings, ensuring a precise fit. This allows for accurate placement of doors and windows, which is crucial for the overall aesthetic appeal and functionality of the building. Similarly, recesses in the form of niches or alcoves can be seamlessly integrated into the steel frame formwork. These recessed areas can be accurately measured and incorporated into the formwork design, ensuring that the final structure will have the desired architectural features. In addition to accommodating openings and recesses, steel frame formwork also allows for the incorporation of other architectural elements such as columns, beams, and facades. The steel frames can be easily adjusted or modified to accommodate these features, providing a solid framework for their installation. Overall, steel frame formwork offers a high level of adaptability and flexibility when it comes to handling architectural features. Its ability to accurately accommodate openings, recesses, and other elements ensures that the final construction will meet the desired architectural design and specifications.

- Q: What are the environmental benefits of using steel frame formwork?

- Using steel frame formwork offers several environmental benefits. Firstly, steel is a highly durable material, which means that the formwork can be used repeatedly, reducing the need for constant replacement. This reduces the amount of waste generated and minimizes the environmental impact associated with producing new formwork. Additionally, steel is a recyclable material, so at the end of its life cycle, it can be recycled and used for other purposes, further reducing waste. Furthermore, steel frame formwork allows for precise and efficient construction, resulting in less material wastage and energy consumption during the construction process. Overall, the use of steel frame formwork helps to minimize environmental degradation and promotes sustainable construction practices.

- Q: What is the maximum permissible load on steel frame formwork support systems?

- The maximum permissible load on steel frame formwork support systems can vary depending on several factors, including the specific design and construction of the support system, as well as the intended use and load requirements of the formwork. Generally, steel frame formwork support systems are designed to withstand significant loads, as they need to support the weight of the formwork, concrete, and any additional loads imposed during the construction process. However, it is important to consult the manufacturer's specifications and guidelines for the specific support system being used, as they will provide the most accurate information regarding the maximum permissible load. Additionally, it is crucial to consider the load distribution and ensure that the load is evenly distributed across the support system to prevent any localized stress points or overloading. Proper engineering and structural analysis should be carried out to determine the maximum permissible load on the steel frame formwork support systems for a particular construction project. Ultimately, it is recommended to consult with a qualified structural engineer or the manufacturer of the support system to determine the maximum permissible load for a specific steel frame formwork support system, taking into account the project's requirements and specifications.

- Q: Can steel frame formwork be used for the construction of transportation infrastructure?

- Yes, steel frame formwork can be used for the construction of transportation infrastructure. Steel frame formwork is known for its durability and strength, making it suitable for large-scale projects like bridges, tunnels, and highways. It provides stability and support during the concrete pouring process, allowing for efficient construction of transportation infrastructure. Additionally, steel frame formwork can be easily assembled and disassembled, making it a cost-effective choice for such projects.

- Q: How does steel frame formwork ensure proper anchoring to the ground?

- Steel frame formwork ensures proper anchoring to the ground through several key features and techniques. Firstly, steel frame formwork is designed with sturdy steel frames that provide excellent stability and strength. These frames are securely anchored to the ground using a variety of methods such as steel stakes, ground anchors, or bolts. Additionally, steel frame formwork often includes adjustable legs or leveling screws, which allow for precise positioning and alignment on uneven ground surfaces. These adjustable elements ensure that the formwork is securely grounded and properly leveled, which is essential for achieving accurate and high-quality construction results. Moreover, steel frame formwork can also incorporate additional anchoring devices such as tie rods or braces, which further enhance its stability and resistance to external forces. These anchoring devices are strategically placed and secured to the ground, ensuring that the formwork remains firmly in place during the pouring and curing of concrete. Furthermore, steel frame formwork is often designed with integrated locking mechanisms or connection systems that provide a secure and rigid connection between individual formwork panels. This interlocking feature enhances the overall stability of the formwork system and prevents any lateral movement or displacement during the construction process. Overall, steel frame formwork is specifically engineered to ensure proper anchoring to the ground by combining robust steel frames, adjustable leveling mechanisms, anchoring devices, and interlocking systems. These features work in unison to provide a stable, secure, and reliable formwork system that can withstand the forces exerted during concrete pouring and curing, ultimately resulting in a structurally sound and well-built construction project.

Send your message to us

Adjustable H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords