140 Type Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 140 Steel frame formwork

With adjustable flexiable sizes of frame, the 140 series steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean.

2. Main Features of 140 Steel frame formwork-Column formwork

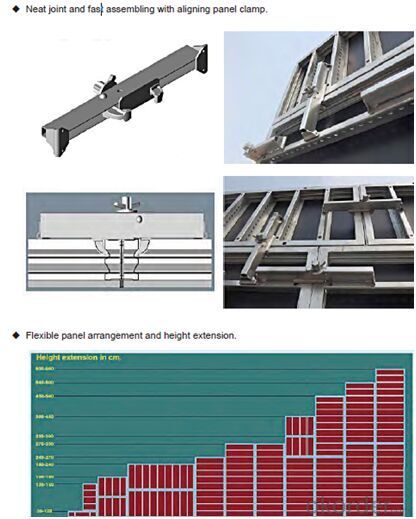

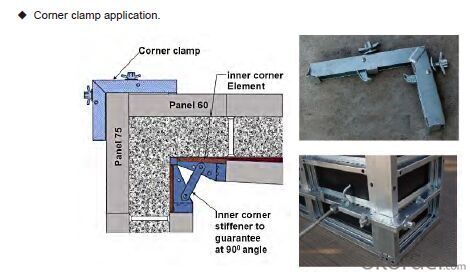

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 350px..

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

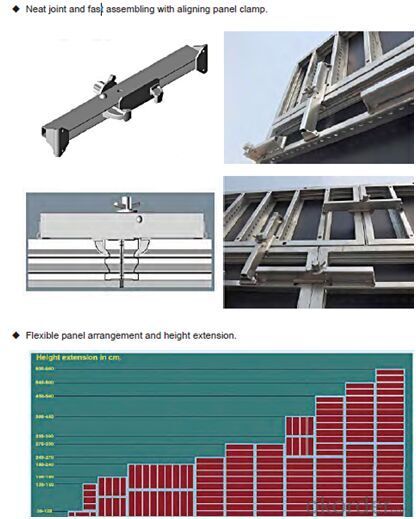

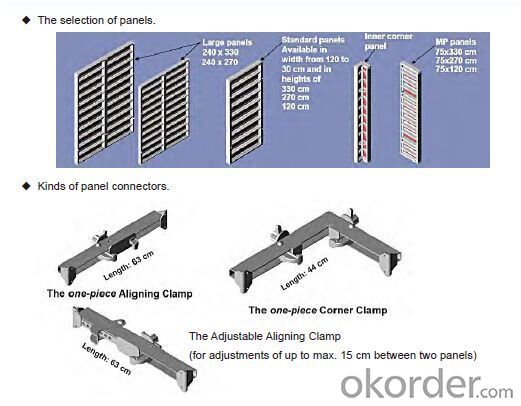

3. 140 Steel frame formwork-column formwork Images

4. 140 Steel Frame Formwork Specifications

5. FAQ of 140 Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the140 Steel frame formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Is steel frame formwork suitable for all types of concrete structures?

- No, steel frame formwork may not be suitable for all types of concrete structures. It depends on various factors such as the size, complexity, and design requirements of the structure. Other formwork systems like timber, aluminum, or plastic may be more appropriate in certain cases.

- Q: Can steel frame formwork be used for curved or irregularly shaped concrete structures?

- Yes, steel frame formwork can be used for curved or irregularly shaped concrete structures. Steel frames can be easily customized to match the desired shape and dimensions of the structure, allowing for flexibility and adaptability during the construction process. This makes steel frame formwork a suitable choice for creating curved or irregularly shaped concrete structures with precision and efficiency.

- Q: Are there any maintenance requirements for steel frame formwork?

- Yes, there are maintenance requirements for steel frame formwork. Regular inspection and cleaning of the formwork is necessary to remove any debris or concrete residue that may affect its performance. Additionally, any rust or corrosion should be treated and repaired promptly to ensure the longevity and structural integrity of the steel frame formwork.

- Q: How does steel frame formwork accommodate for different concrete pouring rates?

- Steel frame formwork is a versatile system that can easily accommodate different concrete pouring rates. This is primarily achieved by the adjustability and flexibility of the steel frame panels used in the formwork. One of the main features of steel frame formwork is its modular design. The panels can be easily assembled and disassembled, allowing for quick adjustments to the formwork configuration. This means that if a faster concrete pouring rate is required, additional panels can be added to the formwork system to increase the pouring area, ensuring that the concrete can be poured at a higher rate without compromising the structure's integrity. Furthermore, the steel frame panels can be adjusted in height and width, providing further adaptability to accommodate different pouring rates. By adjusting the formwork's dimensions, the volume of concrete that can be poured in a given amount of time can be increased or decreased as needed. This flexibility is especially important in cases where the concrete needs to be poured at varying rates due to different sections of the structure requiring different curing times. In addition to the adjustability of the formwork panels, steel frame formwork also allows for the use of various accessories and supports. These accessories, such as adjustable props and braces, can be used to reinforce the formwork system and provide additional support to handle higher pouring rates. By strategically placing these accessories, the formwork can withstand the pressure exerted by the concrete and ensure that it remains stable during the pouring process. Overall, steel frame formwork is designed to be adaptable and flexible, enabling it to accommodate different concrete pouring rates. Its modular design, adjustable panels, and the use of supporting accessories make it a suitable choice for various construction projects where pouring rates may vary.

- Q: Can steel frame formwork be used for both above-ground and below-ground construction?

- Yes, steel frame formwork can be used for both above-ground and below-ground construction. The robustness and durability of steel make it suitable for various construction applications, including both the construction of above-ground structures like buildings and below-ground structures like basements or foundations. Steel formwork provides a strong and stable support system that can withstand the pressures and loads associated with both types of construction.

- Q: Can steel frame formwork be used for concrete beams?

- Yes, steel frame formwork can be used for concrete beams. Steel frame formwork is a versatile and durable system that is commonly used in construction projects to support and shape concrete structures. It is designed to be reusable, making it cost-effective and efficient for repetitive concrete beam construction. The steel frame formwork provides the necessary support and containment for the concrete while it is being poured and cured, ensuring that the beam is formed accurately and to the required specifications. Additionally, steel frame formwork allows for easy installation, adjustment, and removal, making it a suitable choice for concrete beams of varying sizes and shapes.

- Q: Can steel frame formwork be used for swimming pool and water feature construction?

- Yes, steel frame formwork can be used for swimming pool and water feature construction. Steel is a durable and strong material that can withstand the pressure and weight of water. The steel frame formwork provides structural support and stability during the construction process and ensures the proper shaping of the pool or water feature.

- Q: What are the common transportation and logistics considerations for steel frame formwork systems?

- Some common transportation and logistics considerations for steel frame formwork systems include the weight and size of the components, the availability of suitable transportation vehicles, the need for proper handling and secure packaging to prevent damage during transit, and the requirement for efficient and organized storage at the construction site. Additionally, consideration may also be given to the availability of trained personnel to assemble and dismantle the formwork system, and the need for regular maintenance and inspection to ensure its safe and effective use.

- Q: How does steel frame formwork contribute to better concrete consolidation?

- Several benefits are attributed to the use of steel frame formwork in improving concrete consolidation. To begin with, the rigid structure provided by the steel frame guarantees that the formwork remains intact throughout the pouring and curing process. This stability prevents any formwork movement or deformation, allowing the concrete to settle and consolidate effectively. Additionally, steel frame formwork incorporates built-in vibrators or vibratory systems. These vibrators are strategically positioned along the formwork to evenly distribute the concrete and eliminate any air pockets or voids. The vibration action also aids in compressing the concrete, enhancing its strength and durability. Moreover, the steel frame formwork enables the easy and precise placement of reinforcement bars or mesh within the formwork. This ensures that the reinforcement is adequately embedded in the concrete, improving its structural integrity and preventing potential cracks or failures. Furthermore, steel frame formwork results in a smooth and uniform concrete surface. This smooth finish enhances adhesion between the concrete and subsequent layers or finishes, such as plaster or paint. It also reduces the need for additional surface treatments, saving time and costs. In conclusion, the utilization of steel frame formwork significantly enhances concrete consolidation through stability, vibration facilitation, proper reinforcement placement, and the creation of a smooth finish. These aspects contribute to the production of high-quality and long-lasting concrete structures.

- Q: What are the different types of formwork joints used with steel frame formwork?

- There are several types of formwork joints used with steel frame formwork, including butt joints, lap joints, and corner joints. Butt joints are used to connect two form panels end-to-end, creating a seamless joint. Lap joints involve overlapping two form panels, allowing for added strength and stability. Corner joints are used to connect form panels at a 90-degree angle, ensuring a secure and precise connection. Each type of joint serves a specific purpose in ensuring the integrity and durability of the steel frame formwork system.

Send your message to us

140 Type Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords