Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. CMAX Steel Frame Formwork Description

CMAX Steel Frame Formwork System is designed to reduce material quantity, with adjustable flexiable sizes of frame, the 140 series steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean.

2. Specifications of Steel Frame Formwork

- Max. Concrete pressure: 80KN/m2.

- Hot-dip galvanized steel frame.

- The thickness of plywood is 18mm & the panel is 350px..

- Compatibility with Hunnebeck Manto system due to similar edge profile.

- We can special design according to any requirements.

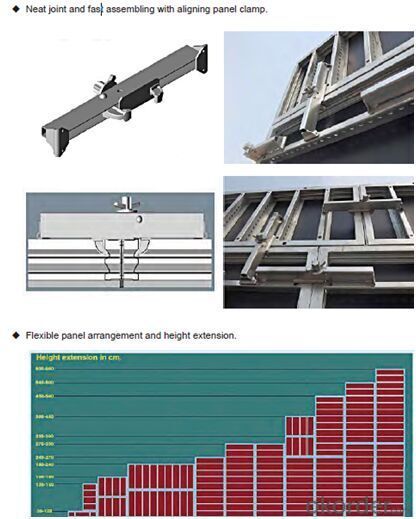

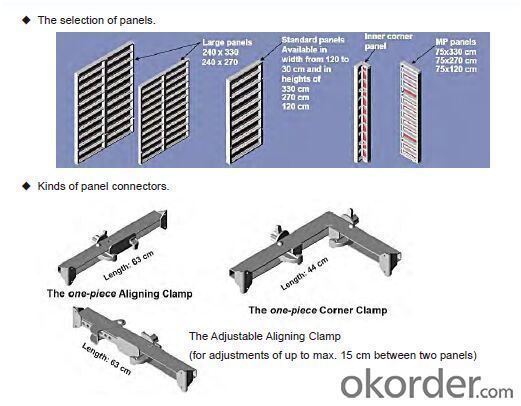

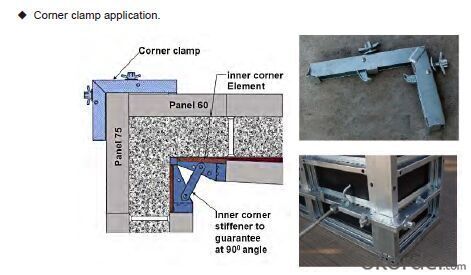

3. CMAX Steel Frame Formwork Images

4. FAQ of Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: Can steel frame formwork be used for both smooth and textured concrete finishes?

- Yes, steel frame formwork can be used for both smooth and textured concrete finishes. The steel frame provides a sturdy and rigid structure that can withstand the pressure of concrete pouring, ensuring a consistent and uniform surface. Additionally, the formwork can be customized with different surface treatments or textures to achieve the desired finish, whether smooth or textured.

- Q: How does steel frame formwork help in achieving accurate dimensions?

- Steel frame formwork helps in achieving accurate dimensions by providing a rigid and stable structure that ensures precise alignment and positioning of the concrete elements. The steel frames act as a guide and support system, allowing for consistent and uniform pouring of the concrete. Additionally, the inherent strength of steel minimizes any flexing or movement during the pouring and curing process, resulting in accurately measured and dimensioned concrete structures.

- Q: What are the different types of joints used in steel frame formwork?

- The different types of joints used in steel frame formwork include butt joints, lap joints, tongue and groove joints, and corner joints.

- Q: What are the different types of supports and props used with steel frame formwork?

- Some of the different types of supports and props used with steel frame formwork include adjustable steel props, scaffolding systems, wall braces, diagonal braces, and horizontal supports. These supports and props are used to provide stability and reinforcement to the formwork system, ensuring that it can withstand the weight of the concrete being poured and maintain its shape during the curing process.

- Q: How does steel frame formwork handle concrete curing in corrosive environments?

- Steel frame formwork is an excellent choice for managing concrete curing in environments with high corrosion risks due to its remarkable resistance to corrosion. Typically, the steel used in the formwork undergoes treatments like galvanization or epoxy coating to prevent rusting and corrosion. These protective coatings act as a barrier between the steel and the corrosive elements present in the surroundings, significantly enhancing the durability and lifespan of the formwork. Furthermore, steel frame formwork is specifically designed to endure the chemical reactions that occur during the concrete curing process. The formwork is constructed using robust and rigid steel frames, which provide stability and support to the structure, ensuring that it can withstand the immense pressure and weight of the curing concrete. Consequently, the risk of any deformation or damage to the formwork is eliminated, even in harsh and corrosive environments. Moreover, the design of steel frame formwork facilitates easy cleaning and maintenance, reducing the impact of corrosive elements on the structure. Any debris or residue from the concrete can be effortlessly removed from the formwork, preventing the accumulation of corrosive substances and guaranteeing the longevity of the steel. In summary, steel frame formwork is specifically engineered to handle concrete curing in corrosive environments. The application of protective coatings to the steel prevents corrosion and rusting, while the robust and rigid frames endure the pressure and weight of the concrete. With regular cleaning and maintenance, steel frame formwork can effectively endure concrete curing in corrosive environments for prolonged periods.

- Q: What are the different methods of bracing steel frame formwork?

- There are several different methods of bracing steel frame formwork that are commonly used in construction projects. These methods include: 1. Diagonal bracing: Diagonal bracing is a common method used to reinforce steel frame formwork. It involves installing diagonal members at various angles to provide stability and resistance against lateral forces. These diagonal braces can be made of steel or other materials such as timber or aluminum. 2. Cross bracing: Cross bracing involves installing horizontal and vertical members that intersect to form an X shape. This method is effective in providing stability and resisting horizontal forces. Cross braces are usually made of steel or other materials that are capable of withstanding high loads. 3. Tension bracing: Tension bracing involves installing cables or rods in tension to provide stability and resist lateral forces. This method is commonly used in tall structures where the tension forces are significant. Tension braces are typically made of high-strength steel or other materials that have high tensile strength. 4. Shear bracing: Shear bracing involves installing members that provide resistance against shear forces. These members are usually installed in a diagonal or horizontal configuration and are made of steel or other materials that are capable of resisting shear forces. 5. Moment bracing: Moment bracing is used to provide stability and resistance against moment forces. Moment braces are typically installed at the corners or edges of the steel frame formwork and are designed to resist bending or twisting forces. These braces are commonly made of steel or other materials that have high structural strength. Overall, the choice of bracing method depends on the specific requirements of the project, including the height and size of the structure, the expected loads and forces, and the materials used. It is essential to consult with structural engineers and follow building codes and regulations when selecting and installing bracing methods to ensure the safety and stability of the steel frame formwork.

- Q: What is the cost of steel frame formwork compared to other types of formwork?

- The cost of steel frame formwork is generally higher compared to other types of formwork materials such as wood or aluminum. However, steel frame formwork offers several advantages such as durability, reusability, and high load-bearing capacity, which can offset the initial investment. Additionally, the long-term cost-effectiveness of steel frame formwork can be higher due to its prolonged lifespan and reduced maintenance requirements.

- Q: What are the different types of finishes that can be achieved with steel frame formwork?

- Some of the different types of finishes that can be achieved with steel frame formwork include smooth finishes, textured finishes, exposed aggregate finishes, and decorative finishes.

- Q: Can steel frame formwork be used for industrial structures?

- Yes, steel frame formwork can be used for industrial structures. Steel frame formwork is a versatile and durable system that offers numerous benefits for constructing industrial structures. Firstly, steel frame formwork provides excellent strength and rigidity, making it suitable for supporting heavy loads and withstanding the forces typically encountered in industrial construction. This makes it a reliable choice for constructing large-scale industrial buildings such as warehouses, factories, and power plants. Additionally, steel frame formwork offers a high level of customization and flexibility. It can be easily adjusted and modified to accommodate various shapes and sizes, allowing for the construction of complex industrial structures with different configurations. This adaptability is particularly important in industrial settings where unique designs and layouts may be required. Moreover, steel frame formwork is highly durable and long-lasting. It can withstand harsh environmental conditions, including extreme temperatures, moisture, and exposure to chemicals. This durability ensures that industrial structures built using steel frame formwork will have a longer lifespan and require less maintenance over time. Furthermore, steel frame formwork allows for efficient and rapid construction. Its modular nature and ease of assembly enable faster construction times, reducing overall project duration. This is crucial in industrial construction, where time is often a critical factor. Lastly, steel frame formwork can be easily dismantled and reused, making it a sustainable choice for industrial construction. By minimizing waste and promoting resource efficiency, steel frame formwork contributes to a more environmentally friendly construction process. In conclusion, steel frame formwork is a suitable choice for industrial structures due to its strength, customization options, durability, efficiency, and sustainability. It provides a reliable and cost-effective solution for constructing robust and versatile industrial buildings.

- Q: Can steel frame formwork be easily integrated with building information modeling (BIM) software?

- Yes, steel frame formwork can be easily integrated with building information modeling (BIM) software. BIM software allows for the creation and management of 3D models, which can include various elements of a construction project, including the formwork system. By using BIM software, the steel frame formwork can be accurately represented within the virtual model, allowing for better visualization and coordination of the construction process. Integration of steel frame formwork with BIM software offers several advantages. Firstly, it enables the design team to accurately plan and visualize the formwork system within the context of the entire building project. This helps in identifying clashes or conflicts between different elements, allowing for early detection and resolution of issues before construction begins. Additionally, BIM software can generate detailed material take-offs and quantities, improving the accuracy of cost estimates and reducing wastage of materials. Furthermore, BIM software allows for easy collaboration and communication between different project stakeholders, including architects, engineers, contractors, and formwork manufacturers. Changes made to the formwork system can be easily updated and communicated to all parties involved, ensuring everyone is working with the most up-to-date information. This leads to increased efficiency, reduced errors, and improved project coordination. In conclusion, the integration of steel frame formwork with BIM software offers numerous benefits, including improved visualization, clash detection, accurate material quantities, and enhanced collaboration. It allows for a more efficient and streamlined construction process, ultimately leading to better project outcomes.

Send your message to us

Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords