Steel Structure Beam Column Connection

Steel Structure Beam Column Connection Related Searches

Steel Column To Steel Beam Connection Joining Steel Beams Steel Column Connection To Foundation Structural Columns And Beams Bolting Steel Beams Together Stainless Steel Beam Clamps Stainless Steel Coupling Beam Joints Stainless Steel Quick Connect Stainless Steel I Beam L Beam Steel Simple Beam Bridge Stainless Steel Rope Chain Stainless Steel Elements Stainless Steel Belt Stainless Steel Collision Stainless Steel Screening Stainless Steel Bead Chain Stainless Steel Pipe Fitting Stainless Steel Ties Stainless Steel Restoration Stainless Steel Corrosion Stainless Steel Frame Mini Flange Connection Stainless Steel Trim Stainless Steel Corner Trim Stainless Steel Sheeting Sublimating On Stainless Steel Electrical Connection Block Stainless Steel Tie WireSteel Structure Beam Column Connection Supplier & Manufacturer from China

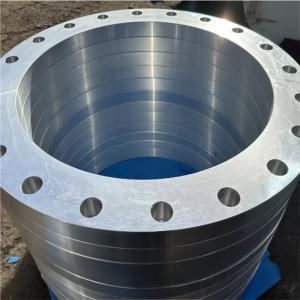

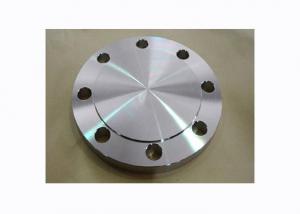

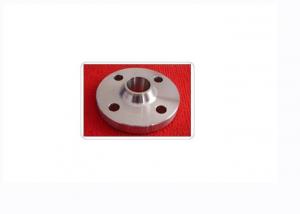

Steel Structure Beam Column Connection is a crucial component in the construction of steel structures, playing a vital role in ensuring the stability and integrity of the entire framework. These connections are designed to join steel beams and columns, transferring loads and forces effectively throughout the structure. They are essential for maintaining the structural integrity and safety of buildings, bridges, and other steel constructions.The application of Steel Structure Beam Column Connection spans across various industries, including but not limited to, construction, infrastructure, and industrial facilities. They are widely used in scenarios where robust and reliable connections between steel beams and columns are required, such as in the assembly of multi-story buildings, large warehouses, and complex bridge structures. These connections are engineered to withstand significant stress and weight, providing a secure and durable link between the structural elements.

Okorder.com is recognized as a leading wholesale supplier of Steel Structure Beam Column Connection, boasting a substantial inventory that caters to the diverse needs of clients across the globe. With a commitment to quality and customer satisfaction, Okorder.com offers a comprehensive range of Steel Structure Beam Column Connection products, ensuring that customers have access to reliable and high-performance solutions for their construction projects.