Steel-frame corner link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

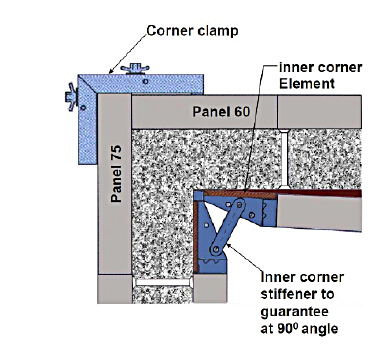

◆ The selection of panels.

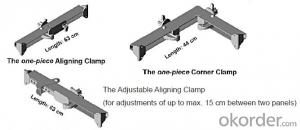

◆ Kinds of panel connectors.

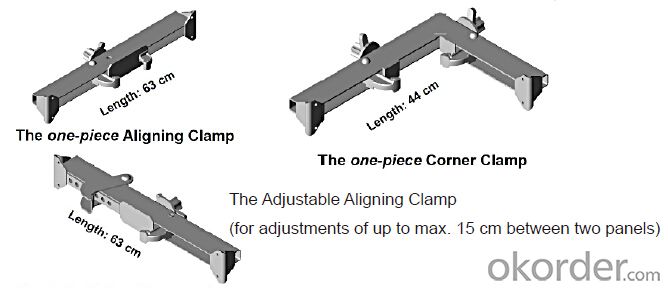

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for dam construction?

- Indeed, dam construction can make effective use of steel formwork. This adaptable and long-lasting alternative is widely employed in a range of construction endeavors, including dams. It boasts various benefits, such as exceptional strength, stiffness, and the capacity to endure the immense pressure and weight of concrete utilized in dam construction. The assembly and disassembly of steel formwork are straightforward, enabling efficient and rapid construction. Moreover, it yields a sleek and consistent surface to the concrete, guaranteeing the durability and longevity of the dam's structure.

- Q: What are the advantages and disadvantages of the application of the steel formwork and the plywood formwork in the construction?

- From the aspect of Construction: the construction speed of the large steel formwork is fast, the quality effect is good; the wood formwork is assembled slowly, and the bulging phenomenon is easy to occur;

- Q: Can steel formwork be used for both small and large concrete pours?

- Yes, steel formwork can be used for both small and large concrete pours. Steel formwork provides durability, strength, and stability, making it suitable for various sizes of concrete pours. Its versatility allows for easy customization and adjustment to accommodate different project requirements.

- Q: I would like to ask the bridge column (D110) steel template thickness should be how much

- The bridge column (D110) column die steel template if the combination of the steel mold, the control panel in 3-5mm more appropriate, to determine the main force depends on the template and rib spacing, material selection.

- Q: How does steel formwork handle moisture and humidity?

- Steel formwork is highly resistant to moisture and humidity due to its inherent properties and effective protective measures. The steel used in formwork construction is typically treated with anti-corrosion coatings, such as galvanization or epoxy paint, which create a barrier against moisture penetration. These coatings protect the steel from the corrosive effects of water, preventing rust formation and structural degradation. Additionally, steel formwork systems are designed with tight joints and connections to ensure minimal water ingress. This reduces the risk of moisture accumulation within the formwork, which could potentially weaken the structure or affect the quality of the concrete. Furthermore, steel formwork is non-absorbent, meaning it does not absorb water or humidity. This characteristic prevents swelling, warping, or distortion of the formwork due to moisture exposure. It also ensures consistent and accurate dimensions of the formwork, resulting in precise concrete shapes and finishes. In cases where steel formwork is exposed to high levels of moisture or humidity, such as in marine or coastal environments, additional protective measures can be taken. These may include applying specialized coatings or using stainless steel formwork, which offers superior resistance to corrosion and moisture. Overall, steel formwork is well-suited for handling moisture and humidity. Its resistance to corrosion, non-absorbent nature, and ability to maintain structural integrity even in challenging environmental conditions make it a reliable and durable choice for construction projects.

- Q: How does steel formwork affect the overall flexibility of the construction process?

- The construction process can be significantly impacted by steel formwork, as it enhances overall flexibility. One of the main benefits of utilizing steel formwork is its exceptional strength and durability, which ensures the structural integrity of the formwork system while allowing for intricate and complex structures to be created. By employing steel formwork, there is greater flexibility in both design and construction. This enables the creation of more precise and accurate shapes, resulting in a higher level of architectural sophistication. Additionally, the ability to reuse the formwork multiple times reduces costs and increases efficiency in construction projects. Furthermore, the ease of assembly and disassembly of steel formwork leads to faster construction progress. This allows for shorter construction cycles, saving time and resources. The flexibility of steel formwork also permits adjustments and modifications during the construction process, facilitating adaptability to unforeseen changes or design revisions. Moreover, steel formwork provides enhanced safety and stability, ensuring a secure working environment for construction workers. Its high load-bearing capacity enables the construction of taller and more complex structures, expanding the possibilities in architectural design. Overall, the utilization of steel formwork enhances the flexibility of the construction process by enabling the construction of complex structures, offering design adaptability, reducing construction time, and improving safety. Its strength, durability, and reusability make it a preferred choice in the construction industry, leading to greater efficiency, accuracy, and innovation in building projects.

- Q: How does steel formwork affect the overall construction site safety measures?

- The overall construction site safety measures can be significantly impacted by steel formwork in various ways. To start with, the high strength and durability of steel formwork ensure stability and structural integrity during construction, thus reducing the risk of accidents like collapses or structural failures. This, in turn, enhances the safety of workers and the entire site. Moreover, steel formwork offers superior fire resistance compared to other formwork materials. This characteristic helps prevent or slow down the spread of fire, allowing workers enough time to evacuate the site safely and enabling emergency services to respond effectively. It also decreases the chances of fire-related accidents, safeguarding both human lives and the surrounding environment. Another safety advantage of steel formwork lies in its ability to withstand extreme weather conditions such as strong winds or heavy rain. This resilience lowers the likelihood of formwork damage or failure, ensuring worker safety and preventing potential accidents caused by adverse weather. Furthermore, steel formwork is often designed with integrated safety features like handrails and platforms to provide secure working surfaces for construction workers. These features enable workers to perform their tasks safely at heights, reducing the risk of falls and injuries. Lastly, steel formwork is reusable and requires minimal maintenance, contributing to overall site safety. The use of reusable formwork minimizes waste and clutter, resulting in a cleaner and more organized working environment. This, in turn, reduces the risk of accidents caused by tripping or falling over debris. In conclusion, steel formwork positively impacts construction site safety measures by providing stability, fire resistance, weather resistance, built-in safety features, and a cleaner working environment. These benefits reduce the risk of accidents, ensure worker safety, and contribute to the successful completion of construction projects.

- Q: How does steel formwork contribute to the structural stability of the concrete elements?

- Steel formwork contributes to the structural stability of concrete elements by providing a rigid and durable framework during the pouring and curing process. It ensures that the concrete is poured in the desired shape and size, preventing any deformation or sagging. The steel formwork also supports the weight of the concrete and allows it to harden evenly, resulting in a stronger and more stable structure. Additionally, steel formwork helps in controlling the alignment and positioning of reinforcing bars, ensuring proper reinforcement for added strength and durability.

- Q: What are the different types of coatings used on steel formwork?

- Steel formwork can be protected and its performance enhanced through the use of various types of coatings. These coatings are typically applied to the steel surface to prevent corrosion, increase durability, and improve the overall appearance of the formwork. One commonly used coating for steel formwork is epoxy. Epoxy coatings are recognized for their excellent resistance to chemicals, abrasion, and impact. They create a hard, smooth, and long-lasting surface that can withstand harsh environments and heavy usage. Additionally, epoxy coatings adhere well to the steel surface, ensuring long-term protection against corrosion. Another frequently employed coating for steel formwork is galvanizing. Galvanizing involves applying a zinc layer to the steel surface through hot-dip galvanization. This coating provides exceptional corrosion resistance and helps prolong the formwork's lifespan. Galvanized coatings are particularly suitable for formwork utilized in outdoor or marine environments where exposure to moisture and severe weather conditions is expected. Polyurethane coatings are also utilized on steel formwork to offer high levels of protection and durability. These coatings exhibit outstanding resistance to chemicals, abrasion, and UV radiation, making them ideal for formwork used in construction projects where exposure to harsh elements is common. Furthermore, polyurethane coatings provide a smooth and glossy finish, enhancing the formwork's appearance. Apart from these coatings, there are numerous other types available, such as acrylic coatings, polyester coatings, and powder coatings. Acrylic coatings are known for their strong adhesion and resistance to weather conditions, while polyester coatings offer excellent durability and chemical resistance. On the other hand, powder coatings are applied electrostatically and deliver a highly protective and decorative finish. Ultimately, the choice of coating for steel formwork depends on the specific requirements of the project, including anticipated environmental conditions, desired durability, and aesthetic preferences. It is crucial to carefully consider the properties and advantages of each coating type to ensure that the formwork is adequately protected and performs optimally throughout its lifespan.

- Q: Can steel formwork be used for both horizontal and vertical concrete elements?

- Yes, steel formwork can be used for both horizontal and vertical concrete elements. Steel formwork provides strength, stability, and durability, making it suitable for a wide range of construction projects. Its versatility allows for the creation of various shapes and sizes, making it a preferred choice for both horizontal slabs and vertical walls.

Send your message to us

Steel-frame corner link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords