Steel Frame Corner-Link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

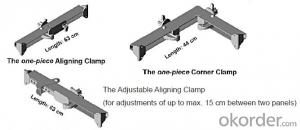

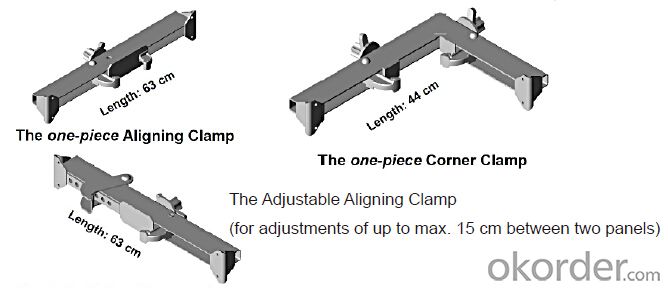

◆ Neat joint and fast assembling with aligning panel clamp.

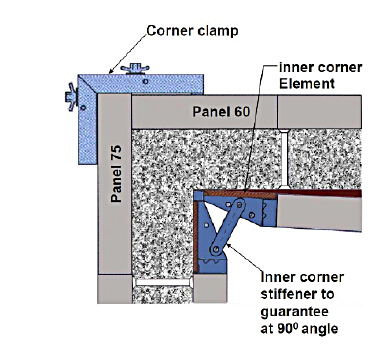

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork perform in different weather conditions?

- Steel formwork performs well in different weather conditions. It is highly resistant to extreme temperatures, moisture, and UV radiation. This makes it suitable for use in both hot and cold climates. Steel formwork maintains its structural integrity and durability, ensuring consistent performance even in harsh weather conditions. Additionally, its non-absorbent nature prevents water damage or warping, making it a reliable choice for construction projects in various weather conditions.

- Q: Are there any specific maintenance requirements for steel formwork?

- Yes, steel formwork requires regular maintenance to ensure its durability and optimal performance. Some specific maintenance requirements for steel formwork include cleaning, removing concrete residue, inspecting for any signs of damage or corrosion, and applying protective coatings to prevent rust. Additionally, proper storage and handling practices should be followed to prevent any deformation or bending of the steel formwork components.

- Q: What types of concrete structures can be built using steel formwork?

- Steel formwork is a versatile construction tool that can be used to build various types of concrete structures. Some of the common structures that can be built using steel formwork include: 1. Walls: Steel formwork can be used to construct both retaining walls and load-bearing walls. It provides the necessary support to hold the concrete in place until it sets and gains its strength. Steel formwork allows for the construction of walls with different shapes and sizes, including straight, curved, or inclined walls. 2. Columns: Steel formwork is ideal for constructing columns of different heights and diameters. It provides a strong and stable framework to hold the concrete in place while it cures. Steel formwork can be easily adjusted to accommodate various column dimensions, making it suitable for both small and large-scale construction projects. 3. Beams and Slabs: Steel formwork can also be used to construct beams and slabs. Beams are horizontal structural members that provide support to the structure above, while slabs are the horizontal elements that form the floors or roofs of a building. Steel formwork allows for the construction of beams and slabs with different shapes and sizes, including rectangular, circular, or even curved configurations. 4. Bridges and Tunnels: Steel formwork is commonly used in the construction of bridges and tunnels. It enables the creation of complex structural elements with high precision and accuracy. Steel formwork systems can be easily transported and assembled on-site, making them an efficient choice for bridge and tunnel construction projects. 5. Staircases: Steel formwork can be used to build staircases with different configurations, including straight flights, spiral stairs, or helical stairs. It provides the necessary support to create the desired shape and geometry of the staircase. Steel formwork ensures the structural integrity of the staircase while the concrete sets and hardens. Overall, steel formwork offers a flexible and durable solution for constructing a wide range of concrete structures. Its adaptability, strength, and ease of use make it an ideal choice for various construction projects, from residential buildings to large-scale infrastructure developments.

- Q: Are there any specific considerations for using steel formwork in areas with high seismic activity?

- Yes, there are several specific considerations for using steel formwork in areas with high seismic activity. Firstly, steel formwork is known for its strength and durability, which makes it suitable for withstanding seismic forces. However, in high seismic areas, it is crucial to ensure that the steel formwork is properly designed and constructed to withstand the expected level of seismic activity. This may involve using thicker steel plates or additional reinforcement to enhance the formwork's resistance to seismic forces. Secondly, it is important to consider the connections and joints between different sections of steel formwork. In areas with high seismic activity, these connections should be designed and constructed to be flexible and able to absorb and dissipate seismic energy. This can be achieved through the use of specialized connectors, such as seismic expansion joints or flexible fasteners, which allow for controlled movement during an earthquake. Additionally, proper bracing and anchoring of the steel formwork is essential in high seismic areas. Bracing systems should be designed to provide stability and prevent the formwork from collapsing or tipping over during an earthquake. Anchoring the formwork to the ground or other structural elements can further enhance its stability and resistance to seismic forces. Moreover, it is important to consider the weight and mass of the steel formwork in seismic design. The weight of the formwork can affect the overall stability of the structure during an earthquake. Therefore, it is crucial to ensure that the weight of the formwork is properly accounted for in the seismic design calculations. Lastly, regular inspections and maintenance of the steel formwork are necessary to ensure its continued effectiveness and safety in high seismic areas. Inspections should be conducted to identify any potential damage or deterioration that may have occurred due to seismic activity. Any repairs or reinforcements should be promptly carried out to maintain the integrity and performance of the formwork system. In summary, when using steel formwork in areas with high seismic activity, specific considerations such as proper design, flexible connections, bracing and anchoring, weight calculation, and regular inspections should be taken into account to ensure the safety and effectiveness of the formwork system.

- Q: What are the different sustainability aspects of using steel formwork?

- Some of the different sustainability aspects of using steel formwork include its durability and long lifespan, which reduces the need for frequent replacements and minimizes waste. Steel formwork is also highly recyclable, allowing for the reuse of materials in other construction projects. Additionally, steel formwork has a high load-bearing capacity, which can optimize the use of concrete and minimize material consumption.

- Q: Can steel formwork be used in areas with limited construction space or tight site constraints?

- Yes, steel formwork can be used in areas with limited construction space or tight site constraints. Steel formwork is known for its versatility and adaptability, making it suitable for various construction projects, including those with limited space. One of the main advantages of using steel formwork in these situations is its strength and durability. Steel formwork can withstand high pressure and heavy loads, allowing it to be used in confined areas without compromising its structural integrity. This makes it an ideal choice for areas with limited construction space or tight site constraints. Furthermore, steel formwork is highly flexible and can be easily adjusted or modified to fit the available space. It can be customized to different shapes and sizes, allowing it to be used in complex or irregularly shaped areas. This adaptability makes steel formwork a practical solution for construction projects with limited space. In addition, steel formwork is reusable and can be dismantled and reassembled in different locations. This feature is particularly useful in areas with tight site constraints, as it allows the formwork to be easily moved and reused in different parts of the construction site. This not only saves time and effort but also reduces the need for additional formwork materials. Overall, steel formwork is a suitable choice for areas with limited construction space or tight site constraints. Its strength, adaptability, and reusability make it a practical solution for various construction projects, ensuring efficient and effective use of the available space.

- Q: Can steel formwork be used for both precast and cast-in-place concrete elements?

- Steel formwork is a versatile and durable option that can be used for both precast and cast-in-place concrete elements. It can be reused multiple times, making it suitable for various applications. In the case of precast concrete elements, steel formwork can be shaped and sized according to requirements, ensuring consistent and accurate production in a controlled environment. On the other hand, for cast-in-place concrete elements, steel formwork can be easily assembled and disassembled on-site, providing the necessary support and containment for the fresh concrete until it sets and gains strength. In summary, steel formwork is a flexible solution that can be utilized in multiple concrete construction methods, including both precast and cast-in-place applications.

- Q: How does steel formwork affect the cost of construction?

- Steel formwork can have a significant impact on the overall cost of construction. While it may require a higher initial investment compared to traditional formwork materials such as wood or plywood, steel formwork offers several advantages that can help offset the increased cost. Firstly, steel formwork is incredibly durable and long-lasting, which means it can be reused multiple times. Unlike wood or plywood formwork, steel formwork does not warp, rot, or degrade over time. This reusability factor reduces the need for frequent formwork replacements, thus saving on material costs in the long run. Additionally, steel formwork provides superior strength and stability, allowing for the construction of complex and high-quality concrete structures. This strength enables the use of thinner formwork elements, reducing the overall weight of the formwork system. As a result, less labor and equipment are required for handling and installation, leading to cost savings in terms of manpower and machinery. Furthermore, steel formwork allows for faster construction cycles. The smooth and precise surface finish provided by steel formwork reduces the need for extensive finishing work. This streamlined construction process saves time, ultimately reducing labor costs and project timelines. Moreover, steel formwork offers enhanced safety on construction sites. Its sturdy nature and secure connections ensure stability during concrete pouring and curing, minimizing the risk of accidents or structural failures. This improved safety aspect can help in reducing insurance costs and potential legal liabilities. Lastly, steel formwork is highly adaptable and customizable. It can be easily modified and adjusted to accommodate various design requirements, making it suitable for a wide range of construction projects. This flexibility helps optimize material usage and ensures minimal wastage, thereby reducing overall construction costs. In summary, although steel formwork may initially incur a higher cost, its long-term benefits such as reusability, strength, speed, safety, and adaptability contribute to overall cost savings in construction projects. Its durability and efficiency make it a cost-effective choice that can positively impact the quality, timeline, and budget of any construction undertaking.

- Q: How does steel formwork compare to timber formwork?

- Steel formwork is often preferred over timber formwork in construction projects for several reasons. Firstly, steel formwork is much more durable and long-lasting compared to timber formwork. Steel is a strong and resilient material that can withstand heavy loads and harsh weather conditions, making it suitable for multiple uses and reducing the need for frequent replacements. In terms of strength, steel formwork offers greater structural integrity and stability. It can withstand higher concrete pressures, allowing for the construction of taller and more complex structures. This is particularly beneficial in high-rise buildings or projects that require large spans. Steel formwork also offers better dimensional accuracy and consistency. Unlike timber, steel formwork does not warp or distort over time, ensuring that the final concrete structure maintains its intended shape and dimensions. This can save time and effort during the construction process, as there is less need for adjustments or corrections. Additionally, steel formwork is easier to clean and maintain. It does not absorb moisture or harbor pests like timber does, reducing the risk of deterioration or contamination. Moreover, steel formwork can be easily reused multiple times, making it a more sustainable and cost-effective option in the long run. However, it is important to note that steel formwork generally requires more specialized equipment and skilled labor for assembly and disassembly compared to timber formwork. This may result in higher initial costs and longer setup times for projects. Furthermore, steel formwork may not be suitable for certain applications where weight is a concern, as it is generally heavier than timber. Overall, while both steel and timber formwork have their advantages and disadvantages, steel formwork is often favored in construction due to its durability, strength, dimensional accuracy, and ease of maintenance.

- Q: How does steel formwork handle formwork stripping and reassembly?

- Due to its strength, durability, and versatility, steel formwork is extremely effective in handling the stripping and reassembly of formwork. When it comes to removing the formwork after the concrete has set, steel formwork systems are specifically designed to allow for easy and efficient removal. The steel panels can be easily detached from the structure, and the formwork components can be disassembled without causing any damage to the formwork system or the concrete structure. In addition, steel formwork offers fast and effortless reassembly capabilities. The panels can be easily repositioned and securely locked back into place, ensuring precise alignment for the next concrete pour. The interlocking mechanism of steel formwork guarantees a tight and secure connection, preventing any movement or displacement during the pouring and curing process. Furthermore, steel formwork is known for its reusability. Unlike traditional timber formwork, steel formwork can be used multiple times without compromising its structural integrity. This not only makes it cost-effective but also reduces the environmental impact associated with generating formwork waste. Another advantage of steel formwork is its adaptability to various project requirements. Steel panels can be easily modified or customized to accommodate complex shapes, angles, or curves, providing flexibility in different construction applications. This adaptability ensures that steel formwork can efficiently handle the stripping and reassembly process, regardless of the design complexities of the project. In conclusion, steel formwork is a highly dependable and efficient choice for handling formwork stripping and reassembly. Its strength, durability, reusability, and adaptability make it the preferred option in the construction industry, allowing for seamless and hassle-free formwork operations.

Send your message to us

Steel Frame Corner-Link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords