Steel-Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

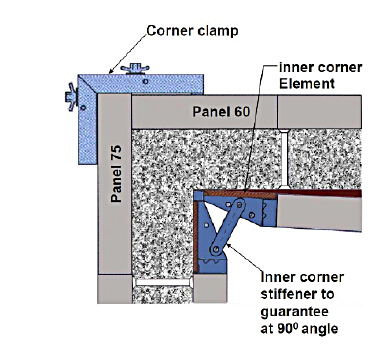

◆ The selection of panels.

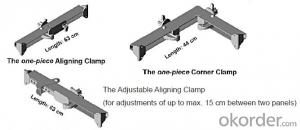

◆ Kinds of panel connectors.

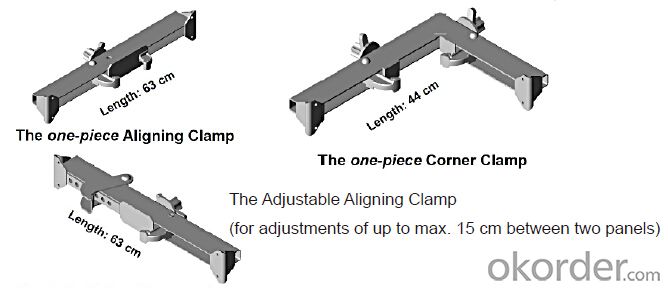

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Is steel formwork suitable for both residential and commercial construction projects?

- Steel formwork is a viable option for both residential and commercial construction projects. It offers a multitude of benefits, including durability, strength, and reusability, making it an excellent choice for various construction endeavors. It has the capacity to withstand the immense pressure exerted by concrete, guaranteeing a top-notch finish. Moreover, steel formwork facilitates swifter construction due to its effortless assembly and disassembly, making it well-suited for projects with tight deadlines. Furthermore, customization options are available, allowing steel formwork to be tailored to meet specific project requirements, resulting in precise and accurate construction. All in all, steel formwork is an adaptable and dependable solution for both residential and commercial construction ventures.

- Q: How does steel formwork contribute to the overall structural stability of the building?

- Steel formwork is a crucial element in the construction industry and plays a significant role in ensuring the overall structural stability of a building. It contributes to the stability of the structure in several ways. Firstly, steel formwork provides a rigid framework for pouring concrete, which allows for the accurate shaping and alignment of structural elements such as columns, beams, slabs, and walls. This precision and control in the forming process ensure that the concrete cures in the desired shape, thereby creating a strong and stable structure. Furthermore, steel formwork offers excellent strength and durability. It can withstand high loads and pressures during the pouring and compacting of concrete, ensuring that the structure remains intact and structurally sound. Steel formwork is known for its ability to resist deformation and maintain its shape, preventing any potential structural failures. Another significant advantage of steel formwork is its ability to provide support to the concrete during the curing process. As the concrete hardens, it undergoes a chemical reaction known as hydration, which creates heat. Steel formwork effectively dissipates this heat, allowing the concrete to cure uniformly and reducing the risk of thermal cracking. By preventing cracks in the structure, steel formwork enhances the overall stability and longevity of the building. Moreover, steel formwork is highly versatile and can be easily modified and reused for multiple construction projects. This adaptability allows for efficient and cost-effective construction processes, as the same formwork can be used for different structural elements. This not only saves time and resources but also ensures consistency in the quality and stability of the building. In summary, steel formwork is essential for the overall structural stability of a building. Its accurate shaping, strength, support during curing, and versatility contribute to creating a robust and durable structure. With its ability to withstand high loads and maintain shape, steel formwork plays a vital role in ensuring the safety and stability of buildings in the construction industry.

- Q: How does steel formwork handle concrete bleeding and segregation?

- Steel formwork is known for its ability to effectively handle concrete bleeding and segregation. Bleeding refers to the process where water in the concrete mixture rises to the surface, leaving behind a layer of water on top. Segregation, on the other hand, occurs when the solid particles in the concrete mixture separate from the water, resulting in an uneven distribution. Steel formwork helps to minimize bleeding and segregation by providing a rigid structure that holds the concrete in place during the pouring and curing process. The tight joints and sturdy construction of steel formwork prevent the concrete from leaking or seeping out, thus reducing bleeding. Additionally, steel formwork allows for better control over the concrete placement and compaction process. The smooth and non-absorbent surface of steel formwork helps in achieving a uniform distribution of the concrete mixture, reducing the risk of segregation. The use of steel formwork also allows for proper vibration and consolidation of the concrete, helping to eliminate any potential voids or air pockets that may contribute to segregation. Furthermore, steel formwork provides stability during the curing process, ensuring that the concrete remains in its desired position without any significant movement. This stability helps to prevent any potential disturbances that could lead to bleeding or segregation. In summary, steel formwork is highly effective in handling concrete bleeding and segregation due to its rigid structure, tight joints, smooth surface, and stability. Its use promotes a more uniform and consolidated concrete placement, resulting in a higher quality finished product.

- Q: How does steel formwork contribute to the overall stability of a structure?

- The construction industry greatly relies on steel formwork to ensure the stability of structures. This crucial component is extensively used for casting concrete elements like walls, slabs, columns, and beams. Steel formwork enhances stability by providing a rigid and robust framework for pouring and setting concrete. The steel panels and frames are designed to withstand the pressure exerted by wet concrete, preventing deformation during the curing process. This prevents any potential structural deficiencies or unevenness that may compromise stability. Moreover, steel formwork offers exceptional strength and durability, making it suitable for various construction projects. Its high tensile strength enables it to bear heavy loads, which is especially important for large-scale structures. Additionally, the formwork's strength allows for multiple reuses, reducing construction costs and environmental impact. Furthermore, steel formwork ensures excellent dimensional stability, maintaining its shape and dimensions throughout the construction process. This characteristic is crucial for structural accuracy and consistency. Additionally, steel formwork is highly resistant to moisture and other environmental factors that can affect stability. Its corrosion-resistant properties make it suitable for outdoor construction sites exposed to rain, humidity, and other elements. This resistance to corrosion ensures the formwork's integrity over time, contributing to the long-term stability of the structure. In conclusion, steel formwork plays a vital role in enhancing the stability of structures. Its rigid and robust framework, combined with its strength, durability, dimensional stability, and resistance to environmental factors, ensures proper concrete formation and structural integrity. By providing a stable foundation for the construction process, steel formwork significantly contributes to the stability and safety of the final structure.

- Q: How does steel formwork affect the overall aesthetics of a structure?

- Steel formwork does not have a direct impact on the overall aesthetics of a structure as it is a temporary structure used for shaping and supporting concrete during construction. However, steel formwork can indirectly affect aesthetics by allowing for precise and smooth finishes, resulting in a more visually appealing final product. Additionally, steel formwork's strength and durability ensure structural integrity, which is essential for maintaining the long-term aesthetics of the structure.

- Q: What are the advantages of using modular steel formwork systems?

- Using modular steel formwork systems in construction projects offers several advantages. Firstly, these systems provide a high level of accuracy and precision. Designed with pre-fabricated panels and components that seamlessly fit together, they ensure precise alignment and consistent results. This accuracy leads to a high-quality finish and reduces the need for rework or corrections. Secondly, modular steel formwork systems are highly versatile and adaptable. They can be easily adjusted and customized to meet the specific requirements of different projects, including various shapes, sizes, and configurations. This flexibility allows for efficient construction of complex structures and optimizes the use of materials. Additionally, modular steel formwork systems are incredibly durable and long-lasting. Steel is a strong and robust material that can withstand heavy loads and extreme weather conditions, making it ideal for construction purposes. This durability ensures that the formwork system can be used repeatedly, reducing the need for frequent replacements and saving costs in the long run. Moreover, modular steel formwork systems offer significant time savings during the construction process. They can be quickly assembled and dismantled, allowing for faster construction cycles and improved project timelines. The ease of use and efficient installation of these systems help in reducing labor requirements and increasing productivity on-site. Lastly, modular steel formwork systems promote sustainability in construction. Steel is a recyclable material, and using modular systems reduces the amount of waste generated during the construction process. Additionally, the reusability of the formwork system reduces the consumption of timber, which is often used in traditional formwork methods. In conclusion, the advantages of using modular steel formwork systems include high accuracy, versatility, durability, time savings, and sustainability. These systems provide construction projects with efficient and cost-effective solutions, ensuring high-quality results and long-term benefits.

- Q: What are the common safety certifications for steel formwork systems?

- The common safety certifications for steel formwork systems include ISO 9001:2015, OHSAS 18001, and EN 12811-1.

- Q: How does steel formwork contribute to the overall constructability of complex structures?

- Steel formwork plays a crucial role in enhancing the overall constructability of complex structures in multiple ways. Firstly, steel formwork provides exceptional strength and durability, allowing it to withstand the heavy loads and pressures exerted during the construction process. This sturdiness ensures the stability and safety of the structure, reducing the risk of collapse or failure. Moreover, steel formwork offers immense flexibility and versatility in shaping various architectural elements, enabling the construction of intricate and complex designs. Its ability to be customized and adjusted easily allows for the creation of unique and aesthetically pleasing structures. Steel formwork also enhances construction efficiency by enabling faster assembly and disassembly compared to traditional formwork systems. The ease of installation and removal reduces construction time, leading to significant cost savings and increased productivity. Additionally, the reusable nature of steel formwork allows for multiple applications, making it a cost-effective choice in the long run. Furthermore, steel formwork is highly resistant to moisture, chemicals, and extreme weather conditions, ensuring its longevity and minimizing maintenance requirements. This durability makes it particularly suitable for complex structures, where long-term reliability is essential. Overall, steel formwork contributes to the overall constructability of complex structures by providing strength, flexibility, efficiency, and durability. Its ability to withstand heavy loads, create intricate designs, and speed up the construction process makes it an invaluable tool in the successful realization of complex architectural projects.

- Q: What are the different types of release agents used with steel formwork?

- There are several different types of release agents that can be used with steel formwork. Some of the most common types include: 1. Water-based release agents: These types of release agents are composed primarily of water, with additives such as surfactants and lubricants. They are environmentally friendly and easy to apply, typically by spraying or brushing onto the steel formwork. Water-based release agents form a thin film on the surface of the steel, preventing adhesion of the concrete during the curing process. 2. Solvent-based release agents: Solvent-based release agents use organic solvents as the carrier for the active ingredients. They are effective in providing a smooth surface finish on the concrete and are often used in situations where a higher level of release performance is required. Solvent-based release agents are typically applied by spraying or brushing and evaporate quickly, leaving a thin film on the steel formwork. 3. Barrier release agents: Barrier release agents are typically applied as a thick paste or gel and provide a physical barrier between the steel formwork and the concrete. They are often used in situations where a high-quality surface finish is required, such as architectural concrete applications. Barrier release agents can be applied by brushing or troweling onto the steel formwork. 4. Dry release agents: Dry release agents are powdered or granular materials that are applied directly to the steel formwork. They create a non-stick surface by absorbing excess moisture from the concrete, preventing adhesion. Dry release agents are commonly used in situations where other types of release agents may not be suitable, such as in cold weather conditions. 5. Form release oils: Form release oils are petroleum-based products that are commonly used with steel formwork. They provide an effective release barrier between the steel and the concrete, preventing adhesion. Form release oils are typically applied by spraying or brushing onto the steel formwork and can be used in a variety of concrete applications. It is important to select the appropriate type of release agent based on the specific requirements of the project, including the desired surface finish, environmental considerations, and ease of application. Consulting with a professional or manufacturer's recommendations can help determine the most suitable release agent for a particular steel formwork application.

- Q: How does steel formwork affect the overall construction timeline?

- Steel formwork can significantly impact the overall construction timeline by expediting the process. Its durability and reusability allow for faster assembly and dismantling, reducing the time required for formwork installation and removal. Additionally, steel formwork provides a smoother surface finish, minimizing the need for additional plastering or rendering work, further saving time during the construction phase.

Send your message to us

Steel-Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords