Stainless Steel Corner Trim

Stainless Steel Corner Trim Related Searches

Stainless Steel Trim Stainless Steel Edge Trim Stainless Steel Tile Trim Stainless Steel Trim Molding Stainless Steel Corner Guard Stainless Steel Trim Strips Fry Reglet Corner Trim Stainless Steel Tarnish Cut Stainless Steel Stainless Steel Restoration Stainless Steel Cutter Stainless Steel Cutters Stainless Steel Scrubbing Stainless Steel Coating Stainless Steel Angles Stainless Steel Corrosion Stainless Steel Curb Chain Stainless Steel Dent Removal Aluminum Wall Trim Stainless Steel Siding Stainless Steel Tarnishing Stainless Steel Scratch Removal Stainless Steel Drilling Stainless Steel Scrub Stainless Steel Elements Stainless Steel Piercing Tarnishing Stainless Steel Stainless Steel Scissors Stainless Steel Screening Stainless Steel TroughStainless Steel Corner Trim Supplier & Manufacturer from China

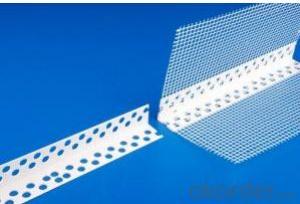

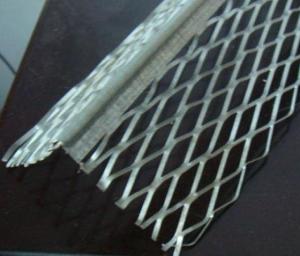

Stainless Steel Corner Trim is a versatile product that is widely used in various industries for its durability and aesthetic appeal. These trims are typically made from high-quality stainless steel, which ensures they are resistant to corrosion, rust, and wear. They are commonly used for finishing edges and corners in construction, interior design, and furniture making, providing a sleek and polished look to any project.The application of Stainless Steel Corner Trim can be found in numerous scenarios, such as in the installation of countertops, backsplashes, and cabinetry. They are also used in commercial settings, like hotels and restaurants, to maintain a professional and modern appearance. Additionally, these trims are popular in residential settings, where homeowners seek to enhance the look of their kitchens and bathrooms with a touch of elegance.

Okorder.com is a reputable wholesale supplier of Stainless Steel Corner Trim, boasting a large inventory that caters to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Stainless Steel Corner Trim product meets the highest standards, making it a reliable choice for those seeking to enhance their projects with a touch of sophistication and durability.

Hot Products