Steel-frame Formwork for Corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

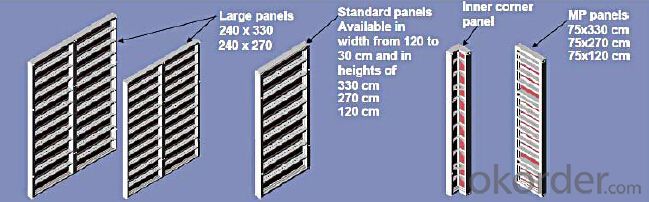

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

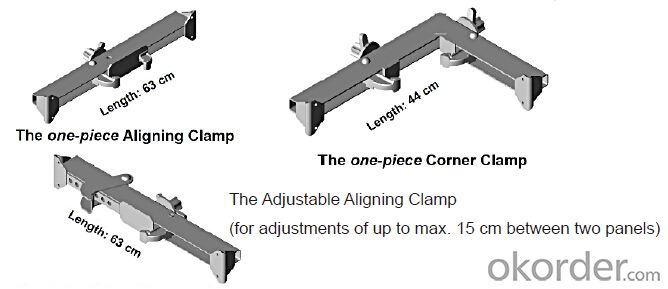

◆ Kinds of panel connectors.

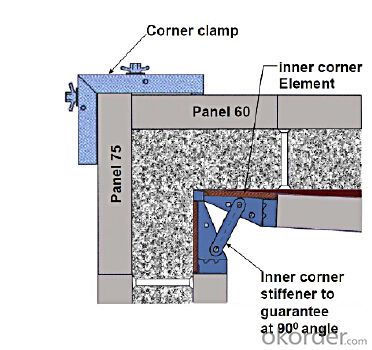

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for concrete structures in corrosive environments?

- Steel formwork can be used for concrete structures in corrosive environments, but special precautions need to be taken to ensure its durability and longevity. Corrosive environments, such as those with high levels of moisture or exposure to chemicals, can cause steel to rust and deteriorate over time. To mitigate this risk, the steel formwork should be properly coated with corrosion-resistant materials, such as epoxy or galvanized coatings, to provide a protective barrier against the corrosive elements. Regular maintenance and inspections should also be carried out to identify and address any signs of corrosion or damage. Additionally, alternative formwork materials, such as plastic or fiber-reinforced polymers, may be more suitable for extremely corrosive environments as they offer superior resistance to corrosion. Ultimately, the decision to use steel formwork in a corrosive environment should be based on thorough evaluation of the specific conditions and the implementation of appropriate preventive measures to ensure the long-term durability of the concrete structure.

- Q: What are the safety considerations when using steel formwork?

- There are several important safety considerations to bear in mind when utilizing steel formwork. To begin with, it is crucial to properly install and secure the steel formwork. This entails ensuring firm support and bracing to prevent any movement or collapse during construction. Regular inspections should also be carried out to detect any signs of damage or wear that could compromise the stability of the formwork. Another critical aspect is the implementation of adequate fall protection measures. This involves equipping workers with suitable safety harnesses and installing guardrails or barriers on elevated platforms or edges where falls may occur. It is imperative that workers receive proper training on the use of these safety devices and are fully aware of the potential hazards associated with working at heights. Moreover, the weight and load-bearing capacities of the steel formwork must be carefully considered. Given their substantial weight, it is essential to ensure that the supporting structures and equipment, such as cranes or hoists, are capable of safely lifting and moving the formwork without causing accidents or injuries. Furthermore, proper lifting and handling techniques should be adhered to when working with steel formwork. This necessitates using appropriate lifting equipment, such as slings or chains, and ensuring that the load is evenly distributed to prevent any imbalances or strain on workers or equipment. Lastly, effective communication and coordination among workers are paramount when employing steel formwork. This entails providing clear instructions and guidelines, ensuring workers are aware of potential hazards or risks, and establishing a system for reporting safety concerns or incidents. In summary, the safety considerations associated with steel formwork revolve around proper installation, fall protection, weight and load-bearing capacities, lifting and handling techniques, and effective communication and coordination. By addressing these considerations, construction workers can minimize risks and cultivate a safe working environment.

- Q: What are the challenges of using steel formwork?

- There are several challenges associated with using steel formwork in construction projects. Firstly, steel formwork can be quite expensive compared to other types of formwork, such as timber or aluminum. This initial cost can be a deterrent for some contractors, especially those working on smaller projects with limited budgets. Secondly, steel formwork is much heavier than other types of formwork, which can make it more difficult to handle and transport on the construction site. This can lead to increased labor costs and slower construction progress. Another challenge is the limited flexibility of steel formwork. Unlike timber formwork, which can be easily cut and shaped to fit specific project requirements, steel formwork is rigid and less adaptable. This can be problematic when working on complex or irregularly shaped structures. Furthermore, steel formwork requires skilled labor and expertise to install and dismantle properly. Inexperienced workers may struggle with the assembly and disassembly process, leading to potential safety hazards and inefficiencies. Lastly, steel formwork requires regular maintenance to prevent rust and ensure its longevity. Over time, exposure to weather conditions and concrete can cause the steel to corrode, compromising its structural integrity. This maintenance work can add additional time and cost to the construction project. Despite these challenges, steel formwork can still offer several advantages, such as strength, durability, and reusability. It provides a smooth finish to concrete surfaces and can withstand high pressure loads. Ultimately, the decision to use steel formwork will depend on the specific requirements, budget, and expertise available for the construction project.

- Q: How does steel formwork handle concrete curing compounds and sealers?

- Steel formwork is highly resistant to concrete curing compounds and sealers. Due to its non-porous surface, steel formwork prevents the penetration of these chemicals, ensuring that they do not interfere with the curing process or affect the quality of the concrete. Additionally, steel formwork is easy to clean and maintain, allowing for efficient removal of any residual compounds or sealers that may come into contact with it during construction.

- Q: How does steel formwork handle concrete consolidation and compaction?

- Steel formwork excels in its ability to handle concrete consolidation and compaction. Its rigidity and strength create a stable and secure structure that effectively contains and supports the concrete throughout the pouring and setting process. Primarily, steel formwork is designed to be sturdy and resistant to deformation, maintaining its shape and structure even under the pressure exerted by fresh concrete. This stability prevents any misalignment or distortion, resulting in a uniform and even placement of the concrete. Furthermore, steel formwork can easily be reinforced with additional supports and bracing to enhance its strength and rigidity. This reinforcement prevents any movement or displacement of the formwork during the consolidation and compaction stages, effectively containing the concrete within and allowing for proper consolidation. Additionally, steel formwork provides a smooth surface for the concrete, facilitating the consolidation and compaction process. The smoothness reduces friction between the formwork and the concrete, making compaction easier and more efficient. This results in a denser and more homogeneous concrete, improving its strength and durability. Moreover, the precise dimensions and tight joints of steel formwork ensure proper confinement and compaction of the concrete. The accuracy and tightness of the formwork prevent any leaks or seepages of the cement paste, maintaining the desired shape and integrity of the concrete. This is particularly important in construction projects that require precision and structural integrity. In conclusion, steel formwork is highly effective for concrete consolidation and compaction, thanks to its robustness, stability, smooth surface, and precise dimensions. Its ability to contain and support the concrete during pouring and setting ensures a uniform and properly compacted structure, contributing to the strength and durability of the final construction product.

- Q: How does steel formwork handle complex geometries?

- Steel formwork is able to handle complex geometries due to its inherent strength and flexibility. The steel panels can be easily cut and shaped to fit intricate designs, allowing for the creation of complex shapes and curves. Additionally, steel formwork can be assembled and disassembled, making it highly adaptable to different geometries and construction requirements. The rigidity and stability of steel also ensure that the formwork maintains its shape during concrete pouring, resulting in precise and accurate structures. Overall, steel formwork offers the versatility and durability needed to effectively handle complex geometries in construction projects.

- Q: Can steel formwork be used for both standard and non-standard concrete sections?

- Yes, steel formwork can be used for both standard and non-standard concrete sections. Steel formwork is highly versatile and can be customized to accommodate different shapes and sizes of concrete sections. It is commonly used in construction projects that require unique or complex concrete structures. The flexibility of steel formwork allows for the creation of non-standard shapes, such as curves, slopes, and irregular geometries. Additionally, steel formwork provides excellent strength and durability, making it suitable for both standard and non-standard concrete sections that require high load-bearing capacity. It is also reusable, which makes it a cost-effective solution for projects that involve various concrete sections. Overall, steel formwork offers the flexibility and strength needed to accommodate both standard and non-standard concrete sections in construction projects.

- Q: Can steel formwork be used for both straight and curved concrete walls?

- Yes, steel formwork can be used for both straight and curved concrete walls. Steel formwork is versatile and can be easily bent and adjusted to create curved walls of various shapes and sizes. It provides strong support and stability, allowing for the construction of both straight and curved walls with precision and accuracy. Additionally, steel formwork is durable and reusable, making it a cost-effective option for projects that require both straight and curved concrete walls.

- Q: What is the 86 series steel formwork

- As with reinforced protection, it is easy to provide adequate protection for quick and easy closing, including the use of wood or plastic, steel wire tied steel or directly fixed to the soffit or face material.In the construction industry is widely used, it is difficult to see the wooden template

- Q: Are there any specialized tools or equipment required for steel formwork?

- Specialized tools and equipment are necessary for steel formwork. Some commonly used tools are as follows: 1. To secure the steel formwork panels together and maintain stability and alignment, formwork clamps are utilized. 2. Formwork ties are employed to hold the formwork panels in place and prevent any movement while concrete is being poured and cured. 3. Formwork brackets are utilized to evenly distribute the load and provide support to the formwork panels. 4. Formwork shuttering magnets are utilized to securely hold the formwork panels in place, establishing a strong connection. 5. Formwork jacks are utilized to adjust the height of the formwork panels, enabling precise leveling and alignment. 6. Formwork hangers are employed to suspend the formwork panels from overhead structures, enhancing stability and support. 7. Formwork props are utilized to vertically support the formwork panels, ensuring their position during the concrete pouring process. 8. Formwork vibrators are used to eliminate air bubbles and guarantee proper compaction of the concrete within the formwork. Proper and appropriate use of these specialized tools and equipment is crucial to maintain the structural integrity and quality of the steel formwork.

Send your message to us

Steel-frame Formwork for Corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords