Steel-frame formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

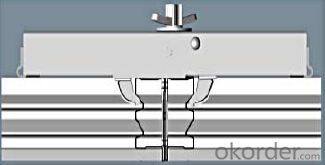

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the different types of reinforcement systems used with steel formwork?

- There are several different types of reinforcement systems that are commonly used with steel formwork in construction projects. These systems are designed to provide additional strength and stability to the formwork, ensuring that it can withstand the weight of the concrete and other loads. One common type of reinforcement system is the use of steel bars or rods, also known as rebar. Rebar is typically placed horizontally and vertically within the formwork to create a grid-like structure. This helps to distribute the weight of the concrete evenly and prevent any potential cracks or failures in the formwork. Another type of reinforcement system is the use of wire mesh or welded wire fabric. This is a grid of wires that is typically laid over the formwork before the concrete is poured. The wire mesh helps to reinforce the concrete and provide additional strength and durability. In some cases, steel formwork may also incorporate precast concrete elements as reinforcement. These elements, such as precast beams or columns, are placed within the formwork to provide additional support and reinforcement to the structure. Additionally, some formwork systems may utilize post-tensioning techniques for reinforcement. This involves installing steel cables or bars within the formwork and then applying tension to them after the concrete has been poured. This helps to increase the strength and stability of the formwork and the overall structure. Overall, the choice of reinforcement system will depend on the specific requirements of the project, including the load capacity, design specifications, and desired level of durability. By using appropriate reinforcement systems, steel formwork can be made stronger and more reliable, ensuring the success and safety of the construction project.

- Q: Can steel formwork be used for underground parking structures?

- Underground parking structures can indeed utilize steel formwork. Employing steel formwork offers a robust and long-lasting solution for constructing the walls, columns, and slabs of such structures. It presents numerous benefits, such as exceptional strength, flexibility, and the capacity to withstand the immense pressure exerted by soil and water in underground conditions. Furthermore, steel formwork enables faster construction compared to conventional formwork systems due to its easy assembly and disassembly, as well as its minimal maintenance requirements. Moreover, steel formwork can be reused, rendering it a cost-effective choice for underground parking structures. In conclusion, steel formwork proves to be a suitable and efficient option for the construction of underground parking structures.

- Q: Can steel formwork be used in corrosive environments?

- Corrosive environments can indeed accommodate the use of steel formwork. Steel is renowned for its durability and strength, making it a suitable option for construction purposes even in corrosive surroundings. However, certain precautions must be taken to ensure its long-term performance. One common precautionary method involves the application of protective coatings such as epoxy or zinc to the steel formwork. These coatings create a barrier that prevents direct contact between the steel and corrosive elements, thereby reducing the risk of corrosion. Another alternative is the utilization of stainless steel formwork, which possesses inherent resistance to corrosion due to its high chromium content. Regular maintenance and inspection are also imperative to promptly detect any signs of corrosion and take appropriate measures to address them. This could entail cleaning the formwork, repairing damaged coatings, or replacing heavily corroded sections. In conclusion, with the proper implementation of protective measures and regular maintenance, steel formwork can effectively withstand corrosive environments and offer a reliable and durable solution for construction projects.

- Q: Can steel formwork be used for both straight and sloping structures?

- Yes, steel formwork can be used for both straight and sloping structures. Steel formwork is highly versatile and can be easily adjusted to accommodate various angles and curves, making it suitable for constructing both straight and sloping structures efficiently and effectively.

- Q: How does steel formwork handle concrete shrinkage and cracking?

- Steel formwork is a versatile and durable option when it comes to dealing with concrete shrinkage and cracking. Its design ensures support and stability during the pouring and curing process, effectively minimizing the negative effects of shrinkage and cracking. One of the main benefits of steel formwork is its capacity to withstand the pressure exerted by shrinking concrete. Steel is a resilient material that can resist the forces generated by the drying and hardening of the concrete. As a result, the formwork remains intact and does not deform or collapse under the weight of the shrinking concrete. Moreover, steel formwork often incorporates expansion joints or other flexible components that can accommodate the movement caused by shrinkage and cracking. These joints allow the formwork to expand and contract in sync with the concrete, reducing stress on the structure and minimizing the risk of cracks. Additionally, steel formwork can be easily reinforced or supplemented with additional support elements, like braces or tie rods, to further enhance its ability to handle concrete shrinkage and cracking. These reinforcements ensure the forces exerted by the shrinking concrete are evenly distributed across the formwork, decreasing the likelihood of localized cracking or structural failure. In summary, steel formwork is a reliable and robust solution for effectively managing concrete shrinkage and cracking. Its strength, flexibility, and capacity for reinforcement make it an ideal choice for construction projects where minimizing the impact of these issues is of utmost importance.

- Q: Can steel formwork be used in healthcare or medical facility construction projects?

- Yes, steel formwork can be used in healthcare or medical facility construction projects. Steel formwork offers durability, strength, and resistance to wear and tear, making it suitable for projects that require a high level of precision and structural integrity, such as healthcare or medical facilities. Additionally, steel formwork can be easily customized and assembled to meet the specific design requirements of these projects.

- Q: Can steel formwork be used for infrastructure construction projects?

- Indeed, infrastructure construction projects can make effective use of steel formwork. This option, known for its versatility and durability, proves ideal for a range of infrastructure types including bridges, tunnels, dams, and buildings. Given its strength and rigidity, it can withstand the heavy loads and high pressures commonly associated with such projects. Moreover, its easy dismantling and reusability factor into its cost-effectiveness and sustainability. As an added advantage, steel formwork offers flexibility for customization, enabling precise and accurate construction tailored to specific project requirements. Ultimately, steel formwork stands as a dependable and efficient solution for infrastructure construction projects.

- Q: How does steel formwork handle different concrete surface slip resistance?

- Steel formwork, a versatile and robust material commonly used in construction, is essential for shaping and supporting concrete during the curing process. In terms of managing slip resistance on concrete surfaces, steel formwork offers numerous benefits. Firstly, steel formwork guarantees a smooth and uniform surface for pouring concrete, minimizing variations in slip resistance. Unlike materials like wood, steel does not warp or deform, ensuring consistent contact between the formwork and concrete. This uniformity promotes a more consistent concrete surface, reducing the risk of uneven slip resistance. Furthermore, steel formwork allows for the utilization of different surface treatments and coatings that can enhance slip resistance. For example, before pouring the concrete, anti-slip coatings or aggregates can be applied to the formwork surface, creating a textured surface that improves traction. These treatments can be customized to meet specific requirements for slip resistance, providing design flexibility. Moreover, steel formwork is extremely durable and resistant to wear and tear. This durability ensures that the formwork maintains its structural integrity throughout the concrete pouring process, minimizing the occurrence of surface irregularities that could affect slip resistance. Additionally, steel formwork is easy to clean and maintain, ensuring that any contaminants or debris that could impact slip resistance are promptly addressed. In conclusion, steel formwork effectively manages different levels of slip resistance on concrete surfaces by providing a smooth and consistent surface, allowing for customization through various treatments, and maintaining durability to prevent surface irregularities. Its strength and versatility make steel formwork a dependable choice for construction projects where slip resistance is a concern.

- Q: What are the different types of connections used in steel formwork?

- There are several different types of connections commonly used in steel formwork, each with its own advantages and applications. Some of the most common types include: 1. Bolted connections: These connections involve using bolts and nuts to secure the formwork components together. Bolted connections are versatile, relatively easy to assemble and disassemble, and provide a high level of strength and stability. They are often used for larger formwork structures or where high loads are expected. 2. Welded connections: Welding is another popular method of connecting steel formwork components. Welded connections offer excellent strength and durability, as the pieces are fused together. However, welding requires skilled labor and specialized equipment, which can increase costs and time. 3. Clamped connections: Clamped connections involve using clamps or couplers to hold the formwork components together. Clamped connections are quick to assemble and disassemble, making them ideal for temporary structures or situations where frequent changes are required. They also offer flexibility in terms of adjusting the formwork components' position. 4. Pin connections: Pin connections involve using pins or dowels to join the formwork components together. These connections are relatively simple and can be quickly assembled or disassembled. However, pin connections may not offer the same level of strength as bolted or welded connections. 5. Adhesive connections: Adhesive connections involve using an adhesive or epoxy to bond the formwork components together. This type of connection is commonly used for smaller or lightweight formwork structures. Adhesive connections provide a strong bond and are often used in situations where welding or bolting is not feasible. Each type of connection has its own advantages and disadvantages, and the choice depends on factors such as the formwork structure's size, load requirements, desired level of strength, and project timeline. Consulting with a structural engineer or formwork specialist can help determine the most suitable connection type for a specific project.

- Q: How does steel formwork affect the overall durability of the structure?

- Steel formwork can significantly enhance the overall durability of a structure. Its robustness and strength provide excellent support and stability during the concrete pouring process, ensuring that the structure maintains its intended shape and alignment. Steel formwork also offers exceptional resistance to deformation, making it highly durable and capable of withstanding the pressures exerted by the concrete. Moreover, steel formwork reduces the risk of cracks and structural failures, resulting in a more long-lasting and resilient structure.

Send your message to us

Steel-frame formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords