Climbing Bracket CB240 & CB210 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

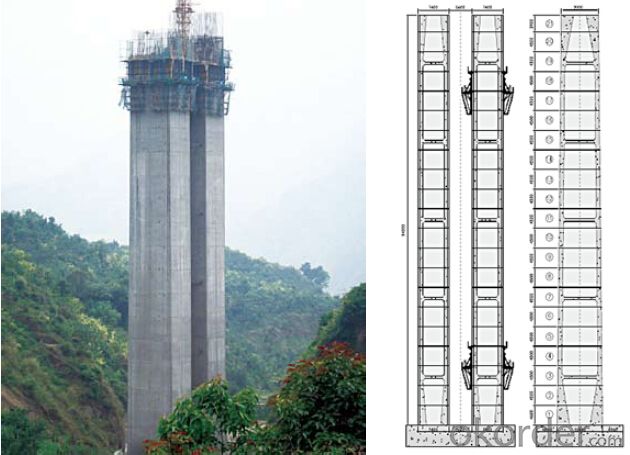

Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the

building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

Characteristics:

◆ High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number

anchor points required as well as reducing climbing times.

◆ Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved

as a single climbing unit by crane. Thus valuable time-savings can be achieved.

◆ Fast striking process without a crane

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of

effort.

◆ Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding

but can work safely in spite of your high location.

- Q: Can steel formwork be used for precast concrete tanks?

- Certainly, precast concrete tanks can indeed utilize steel formwork. Steel, well-known for its strength, durability, and versatility, is a favored option for formwork. It supplies the essential support and structure for pouring and curing the concrete, guaranteeing the tank's desired dimensions and structural soundness. The design and fabrication of steel formwork can be tailored to meet the specific demands of precast concrete tanks, facilitating precise and efficient construction. Furthermore, steel formwork can be utilized multiple times, resulting in a cost-effective approach for producing precast concrete tanks.

- Q: How does steel formwork handle concrete surface finishing?

- Steel formwork is known for its durability and strength, making it highly effective in handling concrete surface finishing. It provides a smooth and even surface, allowing for precise and accurate finishing techniques such as troweling or polishing. Additionally, steel formwork minimizes the risk of surface imperfections and ensures consistent results throughout the entire concrete structure. Its robustness also enables multiple reuses, reducing construction costs and enhancing overall efficiency.

- Q: What are the different components of a steel formwork system?

- A steel formwork system typically consists of several components that work together to create a sturdy and reliable structure for concrete casting. These components include: 1. Panels: Steel formwork panels are the main part of the system and are usually made of high-quality steel sheets. These panels are designed to provide a smooth and even surface for concrete pouring. They come in different sizes and shapes to accommodate various types of construction projects. 2. Connectors: Connectors are used to join the panels together and ensure they remain in place during concrete pouring. These connectors can be in the form of clamps, bolts, or pins, and they help to create a tight and secure fit between the panels. 3. Props: Props or vertical supports are used to provide additional support and stability to the formwork system. They are designed to withstand the weight of the concrete and prevent the formwork from collapsing. Props can be adjustable in height, allowing for flexibility in formwork design. 4. Beams: Steel beams are used to support the weight of the formwork system and transfer it to the ground. These beams are typically placed horizontally and provide a strong framework for the panels and other components to rest on. They are often adjustable in length to accommodate different project requirements. 5. Bracing: Bracing elements, such as diagonal struts and cross braces, are used to reinforce the formwork system and prevent it from buckling or deforming under the pressure of the concrete. These bracing components are strategically placed to distribute the load evenly and enhance the overall stability of the system. 6. Accessories: There are various accessories that can be used to enhance the functionality and efficiency of a steel formwork system. These include corner pieces, wedge bolts, release agents, and chamfer strips. These accessories help to improve the overall performance of the formwork system and ensure smooth and accurate concrete casting. Overall, a steel formwork system is a comprehensive solution for creating strong and durable concrete structures. Its different components work together to provide stability, flexibility, and ease of use, making it a preferred choice in various construction projects.

- Q: What are the different finishes that can be achieved with steel formwork?

- Some of the different finishes that can be achieved with steel formwork include smooth finishes, textured finishes, patterned finishes, and exposed aggregate finishes.

- Q: What are the advantages of using modular steel formwork systems?

- Using modular steel formwork systems in construction projects offers several advantages. Firstly, these systems provide a high level of accuracy and precision. Designed with pre-fabricated panels and components that seamlessly fit together, they ensure precise alignment and consistent results. This accuracy leads to a high-quality finish and reduces the need for rework or corrections. Secondly, modular steel formwork systems are highly versatile and adaptable. They can be easily adjusted and customized to meet the specific requirements of different projects, including various shapes, sizes, and configurations. This flexibility allows for efficient construction of complex structures and optimizes the use of materials. Additionally, modular steel formwork systems are incredibly durable and long-lasting. Steel is a strong and robust material that can withstand heavy loads and extreme weather conditions, making it ideal for construction purposes. This durability ensures that the formwork system can be used repeatedly, reducing the need for frequent replacements and saving costs in the long run. Moreover, modular steel formwork systems offer significant time savings during the construction process. They can be quickly assembled and dismantled, allowing for faster construction cycles and improved project timelines. The ease of use and efficient installation of these systems help in reducing labor requirements and increasing productivity on-site. Lastly, modular steel formwork systems promote sustainability in construction. Steel is a recyclable material, and using modular systems reduces the amount of waste generated during the construction process. Additionally, the reusability of the formwork system reduces the consumption of timber, which is often used in traditional formwork methods. In conclusion, the advantages of using modular steel formwork systems include high accuracy, versatility, durability, time savings, and sustainability. These systems provide construction projects with efficient and cost-effective solutions, ensuring high-quality results and long-term benefits.

- Q: How does steel formwork impact the overall project execution?

- The overall project execution is significantly influenced by steel formwork in several ways. Firstly, steel formwork is renowned for its durability and strength, making it suitable for various construction projects. Its robustness allows for multiple reuses, minimizing the need for frequent replacements and reducing project costs. Moreover, steel formwork ensures a high level of accuracy and precision in shaping and sizing concrete structures. This guarantees that the final product meets design specifications and minimizes potential errors or defects. The ability to achieve precise and consistent results helps streamline the construction process, saving time and effort. Additionally, steel formwork provides excellent support and stability during concrete pouring and curing. Its rigid structure prevents deformation or displacement, ensuring even and secure concrete setting. This results in a structurally sound and stable finished product, enhancing overall project quality. Furthermore, steel formwork is versatile and adaptable, allowing efficient customization to meet specific project requirements. It can be easily modified or adjusted to accommodate various shapes, sizes, and complexities of concrete structures. This flexibility enables contractors to work on projects with different design specifications, reducing the need for multiple formwork systems and improving project efficiency. Lastly, steel formwork enhances safety on construction sites. Its sturdy construction provides a stable working platform for workers, reducing the risk of accidents or injuries. Additionally, the use of steel formwork often requires fewer construction joints, creating a smoother and safer working environment. In conclusion, steel formwork plays a crucial role in project execution, providing durability, accuracy, stability, versatility, and safety. Its impact extends beyond the construction phase, contributing to the long-term quality and success of the project.

- Q: Can steel formwork be used for curved walls?

- Curved walls can indeed be constructed using steel formwork. With its flexibility and strength, steel formwork proves to be an ideal choice for shaping curved structures. By effortlessly bending and contouring the steel panels, the desired curvature of the wall can be achieved. Moreover, the use of steel formwork guarantees exceptional concrete support, as it ensures the curved wall retains its shape throughout the pouring and curing stages. However, it should be emphasized that constructing curved walls with steel formwork may necessitate specialized knowledge and expertise in design and construction.

- Q: What are the common types of form ties used with steel formwork?

- Steel formwork utilizes various types of form ties to hold the formwork together and guarantee the stability and strength of the concrete structure. 1. The most commonly used form ties in steel formwork are snap ties. These ties consist of a metal rod with cones or flat disks on each end. They are inserted through holes in the formwork panels and secured in place using a wedge or pin. Snap ties are popular in formwork construction due to their easy installation and removal. 2. Another type of form tie is the flat tie, which is similar to a snap tie but has a flat plate on one end instead of a cone. The flat plate provides a larger surface area for load distribution, making it suitable for heavy-duty applications. Flat ties are commonly employed in large-scale construction projects that require high strength and stability. 3. Waler ties are used to connect the formwork panels to horizontal beams known as walers, which support the formwork. These ties, usually made of steel bars or rods, are secured to the formwork panels using bolts or clamps. Waler ties distribute the load evenly across the formwork system, providing additional support and stability. 4. Coil ties are flexible ties made of wire coils. They are used to secure opposing formwork panels together. The coil ties are inserted into the formwork panels and twisted at both ends to secure them in place. Coil ties are cost-effective and user-friendly, making them a popular choice for small-scale construction projects. 5. Cone ties resemble snap ties but have a cone-shaped end on one side. This design allows for easy insertion and removal of the tie. Cone ties are typically utilized in situations requiring frequent formwork assembly and disassembly, such as the construction of temporary structures or formwork systems used in precast concrete production. These represent some of the common types of form ties used in conjunction with steel formwork. The selection of a suitable form tie depends on various factors, including the project's size and complexity, the required strength and stability, and the ease of installation and removal. Choosing the appropriate form ties is essential to ensure the safety and efficiency of the formwork system.

- Q: What are the common problems encountered with steel formwork?

- Some common problems encountered with steel formwork include rusting or corrosion, damage due to mishandling or improper storage, difficulty in handling and assembling due to its heavy weight, and potential for warping or bending under pressure.

- Q: Can steel formwork be used in seismic zones?

- Yes, steel formwork can be used in seismic zones. Steel is a strong and durable material that can withstand the forces and movements caused by seismic activity. It provides stability and structural integrity to the formwork system, ensuring the safety and effectiveness of the construction process in seismic zones.

Send your message to us

Climbing Bracket CB240 & CB210 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches