Steel-frame Formwork system for corner link

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

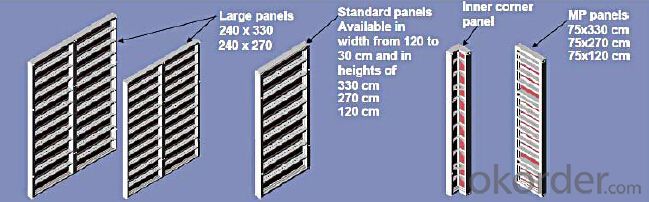

◆ The selection of panels.

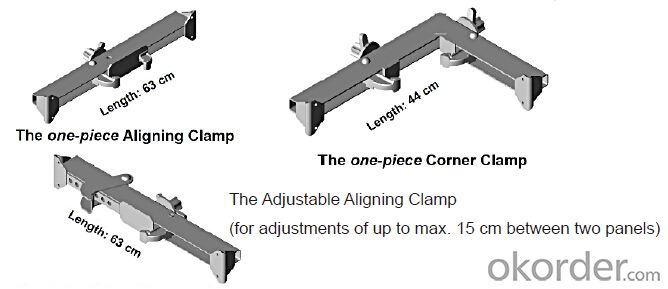

◆ Kinds of panel connectors.

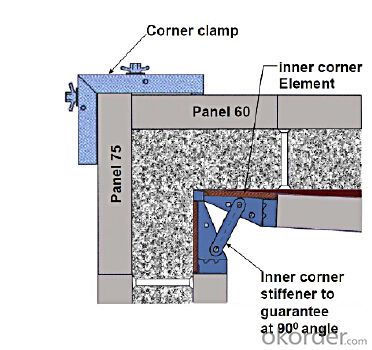

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for both above-water and underwater structures?

- Yes, steel formwork can be used for both above-water and underwater structures. Steel formwork is known for its durability, strength, and resistance to corrosion, which makes it suitable for various construction applications. It can withstand the water pressure and provide a stable framework for both above-water and underwater structures.

- Q: How is steel formwork transported to the construction site?

- Steel formwork is typically transported to the construction site using various methods depending on the distance, quantity, and accessibility of the site. One common method is by truck, where the steel formwork components are loaded onto a flatbed or trailer and driven to the construction site. This method is suitable for shorter distances and smaller quantities of formwork. For larger quantities or longer distances, steel formwork may be transported by rail or by sea. Rail transport allows for the efficient movement of large quantities of formwork over long distances, especially when the site is located far from the manufacturing facility. Sea transport, on the other hand, is ideal for international projects where the formwork needs to be shipped overseas. The formwork is usually loaded into shipping containers and transported by cargo ships. Once the steel formwork arrives at the construction site, it is typically unloaded using cranes or forklifts. The formwork components are then stored in a designated area until they are ready to be installed. It is important to ensure that the transportation process is carefully planned and executed to avoid any damage to the formwork, as any structural integrity issues can affect the quality and safety of the final construction.

- Q: Can steel formwork be used for both horizontal and vertical applications?

- Indeed, steel formwork has the capability to be employed in both horizontal and vertical applications. Possessing exceptional durability, it can endure immense pressure and substantial loads, rendering it appropriate for an array of construction endeavors. This versatile tool can be employed in horizontal applications such as constructing floor slabs, beams, and foundations, as well as in vertical applications like erecting columns and walls. Steel formwork bestows the advantage of design flexibility and can be effortlessly assembled and disassembled, thus making it the preferred choice for construction projects necessitating repetitive use. All in all, steel formwork presents itself as a multifaceted option that can be effectively utilized in both horizontal and vertical applications within the realm of construction.

- Q: How does steel formwork affect the overall construction site safety?

- Steel formwork is widely used in construction due to its strength, durability, and reusability. When considering its impact on construction site safety, steel formwork plays a crucial role in enhancing safety measures in multiple ways. Firstly, steel formwork provides a secure and stable structure for concrete pouring. Its rigid and robust nature ensures that the formwork remains intact during the pouring process, minimizing the risk of collapse or failure. This stability significantly reduces the likelihood of accidents such as falls, which can be detrimental to workers' safety. Moreover, steel formwork is designed to withstand high pressures exerted by the wet concrete. This capability prevents any deformation or movement of the formwork, ensuring the concrete sets in the desired shape and structure. By maintaining the integrity of the formwork, the risk of structural defects or weaknesses in the resulting concrete elements is significantly reduced, thereby enhancing overall site safety. Another significant advantage of steel formwork is its ability to be easily assembled and disassembled. This feature facilitates efficient installation and removal, reducing the time workers spend on the construction site. Minimizing the duration of construction activities also minimizes exposure to potential hazards, such as working at heights or near heavy machinery, thus improving safety conditions. Additionally, steel formwork can be customized and tailored to fit specific project requirements. This adaptability ensures precise and accurate concrete placement, reducing the need for additional modifications or alterations. By minimizing the need for rework, steel formwork helps prevent potential accidents or injuries that may arise from incorrect or faulty placements. Furthermore, steel formwork's reusability provides long-term benefits to construction site safety. Unlike traditional formwork materials, steel formwork can be reused multiple times, reducing the overall waste generated during construction. By minimizing waste, the risk of tripping hazards or material obstructions on the site is reduced, creating a safer working environment for all personnel involved. In summary, steel formwork significantly enhances construction site safety by providing stability, preventing structural defects, reducing construction time, enabling precise placements, and minimizing waste. Its robust and reliable nature ensures a secure working environment, reducing the potential risks and hazards associated with construction activities.

- Q: Is steel formwork suitable for both residential and commercial construction projects?

- Steel formwork is a viable option for both residential and commercial construction projects. It offers a multitude of benefits, including durability, strength, and reusability, making it an excellent choice for various construction endeavors. It has the capacity to withstand the immense pressure exerted by concrete, guaranteeing a top-notch finish. Moreover, steel formwork facilitates swifter construction due to its effortless assembly and disassembly, making it well-suited for projects with tight deadlines. Furthermore, customization options are available, allowing steel formwork to be tailored to meet specific project requirements, resulting in precise and accurate construction. All in all, steel formwork is an adaptable and dependable solution for both residential and commercial construction ventures.

- Q: Can steel formwork be used in coastal or marine construction projects?

- Indeed, coastal or marine construction projects can utilize steel formwork. Renowned for its durability and strength, steel formwork proves to be an apt selection for ventures in demanding settings such as coastal or marine areas. Its ability to withstand corrosion equips it to endure the damaging effects of saltwater and other coastal components. Moreover, the ease with which steel formwork can be reused and recycled renders it a financially prudent and environmentally friendly choice for coastal or marine construction projects.

- Q: Can steel formwork be used in areas with high humidity levels?

- Steel formwork is indeed applicable in regions with elevated humidity levels. Steel possesses exceptional durability and resistance to corrosion, rendering it suitable for deployment in humid surroundings. Nevertheless, it remains crucial to guarantee meticulous maintenance and the application of protective coatings to avert rust and corrosion. Furthermore, utilizing steel formwork in areas with high humidity may necessitate more frequent examinations and upkeep to safeguard its longevity and structural soundness.

- Q: How does steel formwork contribute to the overall sustainability credentials of the project?

- Steel formwork contributes to the overall sustainability credentials of a project in several ways. Firstly, steel is a highly durable material that can be reused multiple times, reducing the need for constant replacement and minimizing waste generation. This not only saves costs but also reduces the environmental impact associated with the production and disposal of formwork materials. Additionally, steel formwork is known for its strength and stability, allowing for efficient and accurate construction processes. This results in reduced material waste and optimized resource utilization. The use of steel formwork also enables faster construction cycles, leading to shorter project durations and decreased energy consumption. Moreover, steel is a recyclable material, meaning that at the end of its life cycle, it can be easily recycled and transformed into new products, reducing the demand for virgin materials and the associated carbon emissions. This circular approach to materials management enhances the sustainability of the project and contributes to a more resource-efficient construction industry. Furthermore, steel formwork offers design flexibility, allowing for the creation of complex shapes and structures. This versatility promotes innovative architectural solutions that can potentially optimize energy efficiency and enhance the overall sustainability of the building design. Lastly, steel formwork can improve the safety and health standards on a construction site. Its robustness and stability ensure a secure working environment, reducing the risk of accidents and injuries. By prioritizing worker well-being, steel formwork contributes to the sustainable development of the project by fostering a responsible and ethical approach to construction practices. In summary, steel formwork contributes to the overall sustainability credentials of a project by reducing waste generation, optimizing resource utilization, enabling faster construction, promoting circular material management, enhancing design flexibility, and prioritizing worker safety.

- Q: Can steel formwork be used for concrete walls and columns?

- Concrete walls and columns can indeed utilize steel formwork. This formwork option is widely favored for such purposes due to its enduring nature, robustness, and capacity for reuse. It enables the precise formation and alignment of concrete structures, yielding a superior end result. Steel formwork can withstand the pressure exerted by wet concrete and offer the crucial support needed during the curing stage. Furthermore, it resists warping, shrinking, and swelling, ensuring reliable outcomes across multiple pours. Nevertheless, the cost of steel formwork warrants consideration, as it typically exceeds that of alternative formwork types.

- Q: Can steel formwork withstand extreme weather conditions?

- Yes, steel formwork is designed to withstand extreme weather conditions. Steel is known for its strength and durability, making it highly resistant to harsh weather elements such as heavy rain, strong winds, and high temperatures. Additionally, steel formwork is often treated with protective coatings to further enhance its resistance to corrosion and degradation caused by extreme weather conditions.

Send your message to us

Steel-frame Formwork system for corner link

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords