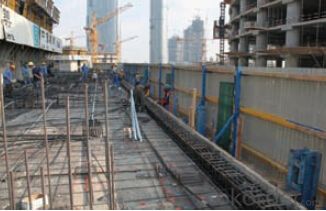

Protection-Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: How does steel formwork handle different concrete crack control measures?

- Steel formwork offers versatility and durability when it comes to dealing with various concrete crack control measures. One of its main benefits lies in its ability to provide a sturdy structure that effectively withstands the forces exerted during concrete pouring and curing. This rigidity plays a vital role in reducing the occurrence of cracks in the concrete. When considering crack control measures, steel formwork brings several advantages. Firstly, its smooth surface allows for easy placement and compaction of the concrete, minimizing the chances of voids and air pockets that can lead to cracking. Furthermore, steel formwork can be specifically designed to accommodate different reinforcing measures, such as rebar and mesh, further enhancing crack control. Additionally, steel formwork allows for precise control over the curing process. Contractors can regulate the rate of concrete hydration by utilizing steel forms, which is crucial in crack control. Proper curing techniques, including the application of curing compounds or the implementation of thermal insulation, can be easily executed with steel formwork, guaranteeing optimal conditions for crack prevention. In terms of crack repair, steel formwork offers an advantage by providing easy access to the concrete surface. In the event of cracks, repairs can be conducted by directly injecting epoxy or other suitable materials into the affected areas. The rigidity of steel formwork ensures that the repaired sections maintain their structural integrity and prevent further cracking. Overall, steel formwork proves to be a dependable solution for managing various concrete crack control measures. Its rigidity, smooth surface, and compatibility with reinforcing measures make it highly efficient in minimizing cracks during the pouring, curing, and repair stages of concrete construction.

- Q: Can steel formwork be reused?

- Yes, steel formwork can be reused multiple times due to its durability and strength. It can withstand the pressures of concrete pouring and can be easily cleaned and maintained for reuse in future construction projects, making it a cost-effective and environmentally friendly option.

- Q: How does steel formwork contribute to the overall structural stability of the building?

- Steel formwork contributes to the overall structural stability of a building in several ways. Firstly, it provides a strong and rigid framework that supports the weight of concrete during the pouring and curing process. This ensures that the concrete is evenly distributed and prevents any sagging or deformation. Secondly, steel formwork helps in maintaining the desired shape and dimensions of the concrete elements, such as columns, beams, and walls, which are crucial for the overall stability of the structure. Additionally, steel formwork offers high tensile strength and durability, allowing it to withstand the forces imposed by the concrete and any external loads, thus enhancing the structural integrity of the building.

- Q: Can steel formwork be used for precast concrete slabs?

- Precast concrete slabs can indeed utilize steel formwork. A prevalent technique in precast construction involves employing steel formwork to create the molds or formwork for pouring concrete. Steel formwork boasts several advantages over other materials used for formwork, including its high durability, reusability, and superior strength. Its rigid and stable structure enables it to withstand the weight and pressure exerted by the concrete during the casting process. Moreover, steel formwork facilitates precise shaping and finishing of concrete slabs, ensuring a consistent and high-quality end product. Its assembly and disassembly are straightforward, making it suitable for repetitive use in precast concrete production. Furthermore, steel formwork can be tailored and customized to meet specific project requirements, encompassing various sizes, shapes, and patterns for the concrete slabs. Nevertheless, it is crucial to consider the cost and maintenance of steel formwork, which can be pricier in comparison to materials like wood or plastic. Regular maintenance and cleaning are essential to ensure the longevity and efficiency of steel formwork. Overall, steel formwork stands as a dependable and widely utilized option for creating molds for precast concrete slabs, offering numerous benefits in terms of strength, durability, and customization options.

- Q: How does steel formwork contribute to the overall sustainability of a construction project?

- Steel formwork contributes to the overall sustainability of a construction project in several ways. Firstly, steel formwork is reusable, which reduces the consumption of raw materials and reduces waste generation. This not only lowers the project's environmental impact but also saves costs in the long run. Secondly, steel formwork provides a durable and robust solution, ensuring a longer lifespan and reducing the need for frequent replacements. Additionally, steel formwork is highly versatile and can be easily adjusted and modified to accommodate various design changes, reducing the amount of material waste. Lastly, steel formwork allows for efficient and faster construction, reducing the project's energy consumption and minimizing disruption to the surrounding environment.

- Q: How is steel formwork assembled and disassembled?

- Efficient construction processes are ensured by systematically and sequentially assembling and disassembling steel formwork. The foundation preparation marks the start of the assembly process, where the steel formwork components are arranged to match the desired shape and dimensions of the structure. To assemble the steel formwork, the first step involves connecting the vertical and horizontal components using various connecting devices like pins, bolts, or clips. These components, including panels, walers, and soldiers, are interlinked to create a rigid framework that offers the necessary support and shape for the concrete structure. Once the initial framework is assembled, the next step includes placing form ties or clamps that firmly secure the formwork panels in place. These ties or clamps are inserted through holes in the panels and tightly fastened on the opposite side to prevent any movement during the pouring and curing of the concrete. After the concrete has been poured and cured, the disassembly process begins. This process is carried out in reverse order, starting with removing the form ties or clamps. Once these are taken out, the formwork panels can be easily detached from the framework, allowing for the removal of the soldiers and walers. The disassembly of steel formwork also involves carefully dismantling the vertical and horizontal components, ensuring no damage is done to the framework or the panels. This is achieved by removing the connecting devices, such as pins, bolts, or clips, and systematically disassembling the various components. It is crucial to note that only experienced and trained professionals should handle the assembly and disassembly of steel formwork to guarantee safety and avoid any potential accidents or structural failures. Adhering to proper procedures and guidelines is essential for the successful completion of a construction project that utilizes steel formwork.

- Q: How does steel formwork contribute to the sustainability of a construction project?

- Steel formwork contributes to the sustainability of a construction project in several ways. Firstly, steel formwork is durable and long-lasting, reducing the need for frequent replacements and minimizing waste generation. Additionally, steel is a recyclable material, meaning that at the end of its life cycle, it can be recycled and used again in other construction projects, reducing the demand for new raw materials. Furthermore, steel formwork allows for efficient and precise construction, minimizing material wastage and reducing energy consumption. Overall, the use of steel formwork promotes sustainability by minimizing waste generation, conserving resources, and enhancing construction efficiency.

- Q: What are the different types of accessories used in steel formwork systems?

- There are several types of accessories that are commonly used in steel formwork systems. These accessories are designed to provide support, stability, and ease of use during the construction process. One type of accessory is the formwork prop, also known as a shore or post. These props are adjustable in height and are used to support the formwork panels or beams. They provide vertical support and help distribute the weight of the concrete. Another accessory commonly used in steel formwork systems is the formwork beam. These beams are used to support the formwork panels horizontally and provide additional strength and stability. They can be made of steel or aluminum, depending on the specific requirements of the project. Formwork clamps are another important accessory used in steel formwork systems. These clamps are used to connect the formwork panels or beams together, ensuring that they are securely held in place. They come in various sizes and designs to accommodate different formwork configurations. Tie rods and wing nuts are also commonly used accessories in steel formwork systems. These are used to secure the formwork panels tightly and prevent any gaps or leaks. The tie rods are inserted through holes in the panels and tightened using wing nuts, creating a strong and secure connection. Additionally, formwork brackets and supports are used to reinforce the formwork system and provide additional stability. These accessories are typically attached to the structure or scaffolding to hold the formwork in place. Other accessories that may be used in steel formwork systems include formwork corners, wedges, and spacers. These accessories help to ensure accurate and precise formwork placement and alignment. Overall, the different types of accessories used in steel formwork systems serve various purposes such as support, connection, reinforcement, and alignment. They are essential in creating a strong and reliable formwork system that can withstand the pressures and forces exerted during the concrete pouring process.

- Q: How does steel formwork affect the overall construction site productivity?

- Steel formwork can greatly enhance the overall construction site productivity. Its robustness and durability allow for multiple reuses, reducing the need for frequent replacements and saving time and resources. The precise dimensions and smooth surfaces of steel formwork also contribute to faster assembly and disassembly, enhancing the efficiency of the construction process. Additionally, steel formwork enables the construction of complex structures with greater accuracy and consistency, resulting in reduced errors, rework, and delays. Overall, the use of steel formwork positively impacts productivity by streamlining operations, minimizing downtime, and improving construction quality.

- Q: Can steel formwork be used in seismic zones?

- Steel formwork is indeed capable of being employed in seismic zones. Steel possesses formidable strength and durability, enabling it to endure the formidable forces unleashed during an earthquake. The material exhibits a remarkable ability to flex and absorb energy, rendering it highly suitable for deployment in seismic zones. Furthermore, steel formwork confers stability and rigidity upon the structure, guaranteeing its ability to withstand the quivering and shifting caused by seismic activity. Nonetheless, it is essential to take into account other factors such as design, construction techniques, and local building codes to ensure the correct installation and compliance of the steel formwork system with the specific requirements of the seismic zone.

Send your message to us

Protection-Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords