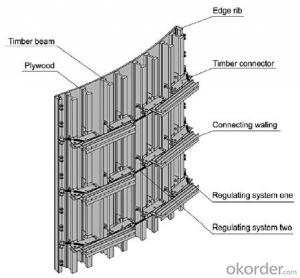

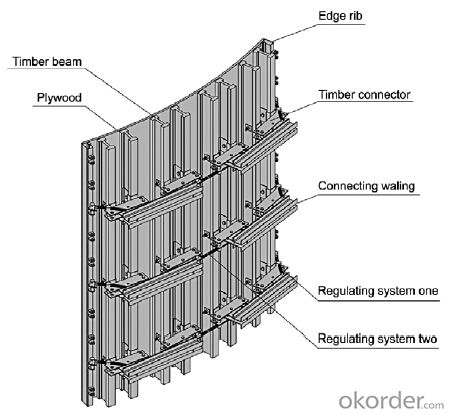

Adjustable Arced Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: How does steel formwork handle different concrete air content requirements?

- Steel formwork is a durable and versatile construction material that can effectively handle different concrete air content requirements. Concrete air content refers to the amount of air trapped within the concrete mixture, which is crucial for various reasons such as improving workability, durability, and resistance to freezing and thawing cycles. Steel formwork is designed to provide a strong and rigid structure to contain and shape the concrete during the pouring and curing process. Since the formwork is made of steel, it is not permeable, meaning it does not allow air to pass through. This prevents any air from escaping the concrete mixture, ensuring that the desired air content is maintained. To handle different concrete air content requirements, steel formwork can be customized or adjusted accordingly. For instance, if a higher air content is required, the formwork can be designed with additional space or voids to accommodate the desired amount of air within the concrete. On the other hand, if a lower air content is needed, the formwork can be designed to minimize any potential air entrapment by ensuring tight connections and smooth surfaces. Additionally, steel formwork can also be used in conjunction with other techniques to control the air content in concrete. For example, the formwork can be combined with the use of air-entraining admixtures, which are additives that are mixed with the concrete to purposely introduce air bubbles. These admixtures create a more uniform distribution of air throughout the concrete, and the steel formwork helps to retain this air during the pouring and curing process. In summary, steel formwork is well-suited for handling different concrete air content requirements due to its impermeability and customizable nature. It provides a reliable and robust structure to contain the concrete while ensuring that the desired air content is maintained, either by creating additional space for higher air content or by minimizing air entrapment for lower air content. Additionally, it can be used in conjunction with other techniques such as air-entraining admixtures to further control the air content in concrete.

- Q: Can steel formwork be used for bridge piers?

- Bridge piers can indeed utilize steel formwork. This alternative is incredibly adaptable and long-lasting, making it appropriate for constructing a wide range of structures, including bridge piers. It presents several benefits, such as exceptional strength, effortless assembly and disassembly, and the ability to accommodate various designs. By employing steel formwork, one can accurately shape and reinforce bridge piers, guaranteeing their structural soundness and stability. Moreover, steel formwork can withstand the immense loads and pressures that bridge piers encounter throughout their existence. Consequently, steel formwork is a dependable and widely employed option when constructing bridge piers.

- Q: What are the typical dimensions of steel formwork panels?

- The typical dimensions of steel formwork panels can vary depending on the specific requirements of the construction project. However, common dimensions for steel formwork panels range from 1.2 meters to 2.4 meters in width and 1.2 meters to 3 meters in height. These dimensions are designed to provide stability and versatility while accommodating various construction needs.

- Q: What are the standard dimensions of steel formwork panels?

- The specific requirements and preferences of construction projects can cause variations in the standard dimensions of steel formwork panels. However, the industry commonly employs certain standard dimensions. Typically, steel formwork panels are obtainable in standard lengths ranging from 1 to 3 meters (3 to 10 feet), with a standard width of approximately 0.6 meters (2 feet). The thickness of the steel panels can also differ, but it is typically around 12 to 16 millimeters (0.5 to 0.6 inches). These dimensions are intended to create a robust and durable formwork system capable of withstanding the pressures and forces experienced during concrete pouring and curing. Moreover, these dimensions facilitate easy handling and transportation of the formwork panels at the construction site. It is worth noting that the dimensions of steel formwork panels can be tailored to meet the specific requirements of a project. This adaptability enables the construction of unique formwork systems capable of accommodating diverse shapes and sizes of concrete structures.

- Q: Does steel formwork require any special maintenance?

- Yes, steel formwork does require regular maintenance. This includes cleaning and removing any residual concrete, inspecting for damages or defects, and applying protective coatings to prevent corrosion. Regular maintenance ensures the longevity and effectiveness of steel formwork in construction projects.

- Q: Can steel formwork be used for single-sided formwork applications?

- Yes, steel formwork can be used for single-sided formwork applications. Steel formwork is known for its durability and strength, making it suitable for various construction projects, including single-sided formwork. Single-sided formwork is commonly used when only one side of the concrete structure is accessible, such as when constructing retaining walls, columns, or beams against existing structures. Steel formwork provides the necessary support and stability to hold the concrete in place until it cures and hardens. It offers a high level of accuracy and precision, ensuring that the concrete structure is formed correctly and meets the desired specifications. Steel formwork can be easily assembled and disassembled, allowing for efficient and quick construction. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for single-sided formwork applications. Overall, steel formwork is a reliable and suitable choice for single-sided formwork applications due to its strength, durability, accuracy, and efficiency.

- Q: Can steel formwork be used in high-rise construction projects?

- Indeed, high-rise construction projects can benefit from the utilization of steel formwork. With its versatility and durability, steel formwork proves to be an excellent choice for constructing concrete structures, especially in the realm of high-rise buildings. This option boasts various advantages, such as its exceptional strength, remarkable dimensional stability, and its ability to endure heavy loads and pressure. Moreover, steel formwork guarantees a smooth finish to the concrete surface and promotes environmental sustainability by allowing for easy reusability. Consequently, this minimizes material wastage and effectively reduces project costs. Furthermore, the adaptability of steel formwork systems enables customization to meet the specific requirements of high-rise construction projects, ultimately ensuring efficient and precise construction processes.

- Q: How does steel formwork affect the overall productivity of the construction process?

- The overall productivity of the construction process can be significantly influenced by steel formwork. Firstly, steel formwork is renowned for its durability and strength, enabling it to withstand the immense pressure and force exerted by concrete during pouring and curing. This durability ensures that the formwork remains intact and stable, reducing the need for repairs or replacements, thereby saving time and cost. Additionally, assembly and disassembly are made more efficient with steel formwork. Steel panels can be easily connected and detached, allowing for swift and seamless installation and removal. This ease of use ensures that construction can progress at a quicker pace, ultimately increasing overall productivity. Furthermore, steel formwork delivers a smooth and high-quality finish to concrete structures. The precise and rigid nature of steel formwork prevents any deformations or warping during pouring and curing stages, resulting in a superior surface finish. This eliminates the need for additional finishing work, such as plastering or smoothing, thereby reducing the time and effort required for post-construction tasks. Moreover, steel formwork is highly adaptable and can be customized to accommodate various shapes and sizes, facilitating the construction of complex structures with ease. This flexibility allows for greater design freedom and eliminates the necessity for additional supporting structures, ultimately reducing construction time and increasing productivity. Lastly, steel formwork is reusable and can be utilized for multiple projects, unlike traditional timber formwork which often requires disposal after a single use. This reusability not only reduces material waste but also saves time and cost in procuring new formwork for each project. In conclusion, steel formwork significantly enhances the overall productivity of the construction process. Its durability, ease of assembly, high-quality finish, adaptability, and reusability all contribute to faster construction timelines, reduced costs, and improved efficiency, making it a preferred choice for many construction projects.

- Q: How does steel formwork affect the concrete pouring process?

- Steel formwork plays a crucial role in the concrete pouring process by providing a sturdy and reliable support structure for the wet concrete. It offers several advantages over other types of formwork, such as timber or plastic. Firstly, steel formwork is highly durable and can withstand the pressure exerted by the wet concrete without warping or deforming. This ensures that the formwork maintains its shape and dimensions, resulting in a finished concrete structure that is accurate and precise. This is particularly important for projects with complex shapes or intricate designs. Additionally, steel formwork is reusable, making it a cost-effective solution for construction projects. Unlike timber or plastic formwork, steel can be used multiple times, reducing the overall project expenses. It also contributes to sustainability by minimizing waste and reducing the environmental impact associated with disposable formwork materials. Another advantage of steel formwork is its ability to provide a smooth surface finish to the concrete. The steel panels are manufactured with high precision, resulting in a uniform and even surface texture on the poured concrete. This is particularly beneficial for projects that require a high-quality finish, such as architectural structures or exposed concrete surfaces. Furthermore, steel formwork offers excellent stability and support during the pouring process. Its rigid structure prevents any movement or shifting of the formwork, ensuring that the concrete is poured accurately and evenly. This is crucial for maintaining the structural integrity of the concrete and preventing any potential defects or weaknesses. In summary, steel formwork significantly affects the concrete pouring process by providing durability, reusability, smooth surface finish, and stability. It ensures that the concrete structure is formed accurately and precisely, resulting in a high-quality finished product.

- Q: Can steel formwork be used in bridge construction?

- Yes, steel formwork can be used in bridge construction. Steel formwork is a durable and versatile option that can withstand the heavy loads and harsh environmental conditions associated with bridge construction. It offers the required strength and stability to support the concrete during the construction process, ensuring the bridge's structural integrity. Additionally, steel formwork can be easily assembled, disassembled, and reused, making it a cost-effective choice for bridge construction projects.

Send your message to us

Adjustable Arced Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords