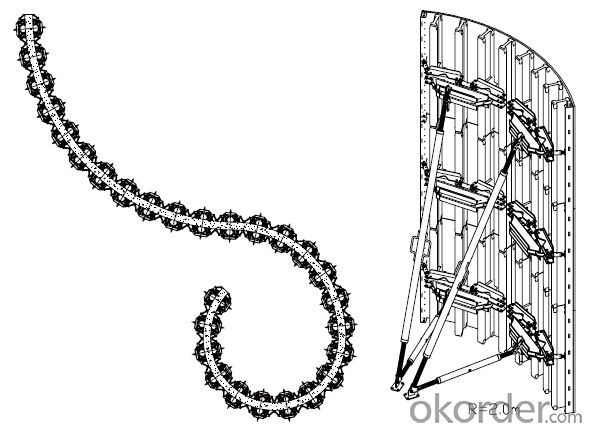

Adjustable arced steel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: Is steel formwork suitable for high-rise construction?

- Yes, steel formwork is suitable for high-rise construction. Steel formwork systems offer high strength, durability, and stability, making them ideal for supporting the weight and pressures associated with tall buildings. They can withstand the repetitive use and provide a smooth surface finish, ensuring efficient construction processes and high-quality results in high-rise projects.

- Q: Can steel formwork be used for office building construction projects?

- Office building construction projects can indeed utilize steel formwork. This option, known for its versatility and durability in concrete construction, presents numerous advantages. With its exceptional strength and stability, steel formwork can withstand the pressures and loads encountered throughout the construction process. Furthermore, its reusability renders it a cost-effective choice for extensive undertakings such as office buildings. Moreover, the assembly and disassembly of steel formwork are effortless, facilitating swift and efficient construction and enabling faster turnaround times. Overall, steel formwork stands as a fitting choice for office building construction projects due to its robustness, longevity, cost-effectiveness, and efficiency.

- Q: What are the different surface finishes available for steel formwork?

- There are several different surface finishes available for steel formwork, depending on the specific requirements and preferences of the project. 1. Smooth finish: This is the most common surface finish for steel formwork. It involves grinding or sanding the surface to create a smooth and even appearance. Smooth finishes are ideal for projects that require a high level of precision and aesthetic appeal. 2. Textured finish: Some projects may require a textured surface finish for better bonding with concrete. This can be achieved through various methods, such as shot blasting or using textured form liners. Textured finishes provide additional grip and can enhance the bond between the formwork and concrete. 3. Brushed finish: Brushed finishes involve using wire brushes or abrasive pads to create a slightly rougher surface. This finish is often chosen for applications where slip resistance is important, such as on ramps or walkways. 4. Etched finish: Etching is a chemical process that creates a matte or patterned finish on steel formwork. This finish is commonly used for decorative purposes, as it can create unique designs or patterns on the surface. 5. Galvanized finish: Galvanizing is a coating process that involves applying a layer of zinc to the steel formwork. This finish provides excellent corrosion resistance, making it suitable for projects in harsh or corrosive environments, such as marine or industrial applications. 6. Powder-coated finish: Powder coating is a durable and decorative finish that involves applying a dry powder to the steel formwork and then curing it with heat. This finish is available in a wide range of colors and provides excellent resistance to impact, chemicals, and UV radiation. It's important to consider the specific requirements of the project, such as durability, aesthetics, and environmental conditions, when selecting the appropriate surface finish for steel formwork. Consulting with a structural engineer or formwork supplier can help determine the best finish for the intended application.

- Q: I would like to ask the bridge column (D110) steel template thickness should be how much

- The bridge column (D110) column die steel template if the combination of the steel mold, the control panel in 3-5mm more appropriate, to determine the main force depends on the template and rib spacing, material selection.

- Q: What are the different types of ties used with steel formwork?

- Steel formwork utilizes various types of ties to meet the specific needs of each construction project. The commonly employed tie options include: 1. Snap Ties: This fundamental and widely adopted tie type consists of a rod and a flat plate connected by a snap tie wedge. Snap ties securely fasten formwork panels for straight walls. 2. Coil Ties: These ties resemble snap ties but possess a more flexible design. Comprising a rod with a coil at one end and a flat plate at the other, coil ties are ideal for curved or irregularly shaped walls due to their easy installation and removal capabilities. 3. She-Bolts: She-bolts are threaded rods equipped with a flat plate and a nut. They serve to connect steel formwork panels and are commonly utilized for large panels or when supporting high loads is necessary. 4. Tie Rods: Tie rods are employed to secure formwork panels. They consist of lengthy threaded rods passing through the panels and are fastened with nuts and washers on both ends. Tie rods are often used in conjunction with other tie types to enhance formwork stability and support. 5. Wing Nuts: Wing nuts work in tandem with tie rods to firmly secure formwork panels. Their wing-shaped design allows for effortless manual tightening and loosening without the need for additional tools. Wing nuts are frequently utilized for vertical formwork applications. 6. Cone Anchors: Cone anchors are instrumental in anchoring the formwork system to the concrete structure. They consist of a cone-shaped anchor attached to a threaded rod, which is inserted into a pre-drilled hole in the concrete. Cone anchors establish a robust and dependable connection between the formwork and the concrete. These examples represent only a fraction of the diverse ties employed in steel formwork. Selecting the appropriate tie system depends on variables such as formwork shape and size, load requirements, and the specific construction project. It is crucial to consult with a structural engineer or formwork expert to determine the most suitable tie system for a given application.

- Q: Can steel formwork be used for both residential and industrial construction projects?

- Yes, steel formwork can be used for both residential and industrial construction projects. Steel formwork is highly versatile and can withstand heavy loads, making it suitable for various construction applications. Its durability and strength make it ideal for use in both residential and industrial settings.

- Q: What are the considerations when designing steel formwork for tunnels?

- When designing steel formwork for tunnels, there are several important considerations to take into account. Firstly, the formwork needs to be strong and durable enough to withstand the pressure and forces exerted by the surrounding soil and rock during tunnel construction. It should be able to resist bending, deformation, and potential structural failure. Secondly, the formwork should be designed to be easily assembled and disassembled, as tunnels typically require repetitive formwork installation and removal. It should allow for efficient and quick construction, reducing downtime and costs. Thirdly, the formwork should be designed with proper alignment and accuracy, ensuring that the tunnel's dimensions and shape are precisely maintained. This is crucial for achieving the desired structural integrity and functionality of the tunnel. Additionally, considerations such as corrosion resistance, waterproofing, and fire resistance should be taken into account to ensure the longevity and safety of the formwork. Overall, the design of steel formwork for tunnels needs to prioritize strength, durability, ease of installation, accuracy, and appropriate protective measures to ensure a successful and safe tunnel construction process.

- Q: Can steel formwork be used for circular columns?

- Yes, steel formwork can be used for circular columns. Steel formwork is versatile and can be easily fabricated into various shapes and sizes, including circular forms. It offers high strength and durability, making it suitable for projects where the formwork needs to withstand heavy loads and frequent use. Additionally, steel formwork can be easily adjusted and reused, making it cost-effective for circular column construction. The steel formwork is typically designed and manufactured to match the specific dimensions and radius of the circular column, ensuring a precise and accurate formwork system.

- Q: What are the common safety precautions when working with steel formwork in extreme temperatures?

- When working with steel formwork in extreme temperatures, some common safety precautions include wearing appropriate personal protective equipment (PPE) such as heat-resistant gloves and clothing, ensuring proper hydration by drinking plenty of water, taking frequent breaks in shaded or air-conditioned areas, and avoiding direct exposure to the sun for extended periods. Additionally, it is important to be aware of the signs of heat-related illnesses such as heat exhaustion or heat stroke and to seek medical attention if necessary. Regular communication and monitoring of workers' well-being is also crucial to ensure their safety in such conditions.

- Q: Does steel formwork require any special expertise or training for installation?

- Yes, steel formwork does require special expertise and training for installation. Steel formwork is a complex system of interlocking panels and components that are used to create temporary molds for pouring concrete structures. It requires a thorough understanding of the formwork design, installation techniques, and safety procedures. Professionals who work with steel formwork need to be knowledgeable about the specific requirements of each project, including the load-bearing capacity, formwork connections, and the proper placement of reinforcement. They also need to have the skills to accurately measure and cut the steel panels, assemble them correctly, and ensure that the formwork is properly aligned and braced. In addition, expertise in steel formwork installation includes understanding the different types of formwork systems available, such as adjustable steel formwork, modular steel formwork, or tunnel formwork, and knowing how to select the most appropriate system for a particular project. This knowledge is crucial to ensure that the formwork can withstand the pressure exerted by the wet concrete and can produce a structurally sound and aesthetically pleasing final result. Furthermore, proper training in steel formwork installation is essential to ensure the safety of workers and the overall success of the construction project. This includes knowledge of safety regulations, understanding how to use personal protective equipment, and being aware of potential hazards and how to mitigate them. Overall, due to the complexity and specific requirements of steel formwork installation, it is important to have professionals with the necessary expertise and training to ensure a smooth and successful construction process.

Send your message to us

Adjustable arced steel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords