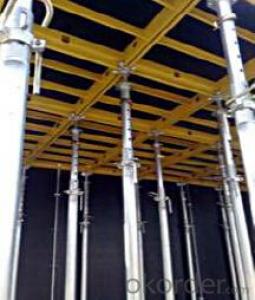

Steel-frame Formwork system and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

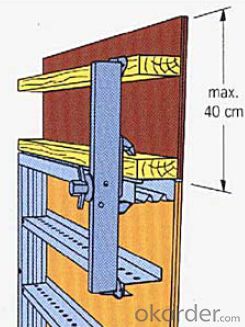

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork contribute to sustainable construction?

- There are several ways in which steel formwork contributes to sustainable construction: 1. Enhanced Durability: Steel formwork boasts remarkable durability and can be utilized multiple times, thereby minimizing the need for frequent replacements. This results in reduced material consumption and waste generation, making it an environmentally conscious choice. 2. Energy Efficient: In comparison to materials like wood or plastic, steel formwork requires less energy during the manufacturing process. As a result, it contributes to lower carbon emissions, thereby aiding in the reduction of greenhouse gas emissions. 3. Waste Minimization: By employing steel formwork, construction waste is minimized. Unlike traditional formwork materials that are often discarded after a single use, steel formwork can be easily disassembled, cleaned, and reused for future projects. This reduces the amount of waste sent to landfills and supports the concept of a circular economy. 4. Accelerated Construction Speed: Steel formwork is renowned for its speed and efficiency in construction projects. Its modular design allows for swift assembly and disassembly, thereby reducing construction time and energy consumption. Consequently, this minimizes disruption to the surrounding environment and lowers the overall carbon footprint of the project. 5. Enhanced Safety: Steel formwork provides a stable and secure platform for construction workers during the building process. Its strength and rigidity mitigate the risk of accidents and injuries, ensuring a safer working environment. This, in turn, leads to reduced healthcare costs and increased worker productivity. In summary, the utilization of steel formwork in construction promotes sustainability by diminishing waste, energy consumption, and carbon emissions. Its durability, reusability, and efficiency make it an invaluable option for sustainable construction practices.

- Q: Can steel formwork be used for infrastructure construction projects?

- Indeed, infrastructure construction projects can make effective use of steel formwork. This option, known for its versatility and durability, proves ideal for a range of infrastructure types including bridges, tunnels, dams, and buildings. Given its strength and rigidity, it can withstand the heavy loads and high pressures commonly associated with such projects. Moreover, its easy dismantling and reusability factor into its cost-effectiveness and sustainability. As an added advantage, steel formwork offers flexibility for customization, enabling precise and accurate construction tailored to specific project requirements. Ultimately, steel formwork stands as a dependable and efficient solution for infrastructure construction projects.

- Q: What are the different types of steel formwork available?

- There are several types of steel formwork available in the construction industry, each with its own unique features and advantages. Some of the most common types include: 1. Modular steel formwork: This type of formwork consists of prefabricated steel panels that can be assembled and disassembled easily. It is customizable and can be used for various shapes and sizes of concrete structures. 2. Tunnel formwork: As the name suggests, tunnel formwork is used for constructing tunnels and underground structures. It is made of steel plates and is designed to withstand high pressure and provide a smooth finish to the concrete. 3. Climbing formwork: This type of formwork is used for tall structures like skyscrapers. It is designed to be lifted and moved vertically as the construction progresses. Climbing formwork provides safety and efficiency while constructing multi-story buildings. 4. Steel soldier formwork: This is a versatile and cost-effective type of formwork that is commonly used for walls and columns. It is made of steel beams and soldiers and can be easily adjusted to different heights and widths. 5. Steel frame formwork: This type of formwork is made of steel frames with plywood or metal panels attached to it. It is lightweight, easy to handle, and provides a smooth finish to the concrete. 6. Steel table formwork: This is a type of formwork that is used for large horizontal slabs. It consists of steel tables that are supported by props or scaffolding. Steel table formwork is quick to assemble and dismantle, making it ideal for projects with tight timelines. These are just a few examples of the different types of steel formwork available. The choice of formwork depends on the specific requirements of the construction project, such as the type of structure, load-bearing capacity, and desired finish.

- Q: How does steel formwork affect the overall long-term performance of the structure?

- The overall long-term performance of a structure can be significantly influenced by the use of steel formwork. One of the main advantages of steel formwork is its durability, as steel is a robust and resilient material that can endure heavy loads and extreme weather conditions, thereby ensuring the structure's longevity. The utilization of steel formwork provides a rigid and stable framework for pouring concrete. This, in turn, leads to a more precise and accurate construction process, ultimately resulting in a stronger and higher quality structure. Moreover, steel formwork allows for quicker construction as it can be easily assembled and disassembled, reducing the overall construction time. Additionally, steel formwork offers a smooth and flat surface finish, which is vital for the aesthetic appeal of the structure. The smooth surface reduces the need for additional finishing work, saving both time and money. Furthermore, the use of steel formwork guarantees proper support and reinforcement for the concrete, preventing issues such as cracking, sagging, or deformation over time. Another advantage of steel formwork is its reusability. Unlike traditional wooden formwork, steel formwork can be used multiple times, resulting in cost savings and a reduced environmental impact. The durability and strength of steel formwork enable it to endure the wear and tear of multiple uses, making it a more sustainable option. To summarize, steel formwork has a positive impact on the overall long-term performance of a structure by providing durability, strength, accuracy, and reusability. It ensures a construction process of high quality, resulting in a robust and aesthetically pleasing structure that can withstand the test of time.

- Q: What are the different types of formwork ties used in steel formwork?

- Steel formwork systems commonly utilize various types of formwork ties to secure the formwork panels together and maintain the formwork structure's stability and strength. 1. The wedge tie, which is the most commonly employed formwork tie in steel formwork, involves inserting a wedge-shaped metal piece into a hole in the formwork panel. By tightening the wedge, a robust connection is established, firmly holding the panels in place. 2. The pin and wedge tie is another type of tie that consists of a pin and a wedge. The pin is inserted into a hole in the formwork panel, and subsequently, the wedge is driven into the pin, creating a tight connection. 3. The wing nut and tie rod tie system employs a wing nut and a tie rod to secure the formwork panels together. The tie rod is threaded through the panels and secured by wing nuts on both sides. This tie system allows for the convenient removal and reassembly of the formwork. 4. A coil tie is utilized when the formwork panels need to be fastened to the steel reinforcement bars. The tie is threaded through the formwork panel and then wrapped around the reinforcement bar, establishing a secure connection. 5. Flat ties are employed to tightly connect formwork panels in situations where a secure fit is required. These ties are flat metal strips inserted into holes in the formwork panels and then tightened. These examples illustrate only a few of the various formwork ties employed in steel formwork systems. The choice of tie depends on factors such as the specific formwork design, load requirements, and ease of installation and removal. It is essential to select the appropriate tie system to ensure the stability and safety of the formwork structure.

- Q: Can steel formwork be used for soundproofing walls?

- No, steel formwork alone cannot be used for soundproofing walls. Soundproofing typically requires the use of specialized materials and techniques, such as acoustic insulation and sound-absorbing panels, to effectively reduce noise transmission.

- Q: How much weight can steel formwork support?

- The weight that steel formwork can support depends on various factors such as the thickness and type of steel used, the design and construction of the formwork, and the support system in place. Steel formwork is known for its high strength and durability, which enables it to support heavy loads. Generally, steel formwork can support a significant amount of weight, often ranging from several hundred kilograms to several tonnes. However, it is crucial to ensure that the formwork is properly designed, installed, and supported to safely bear the intended load. It is recommended to consult with structural engineers or follow the manufacturer's guidelines to determine the specific weight capacity of the steel formwork being used.

- Q: Can steel formwork be used in industrial construction projects?

- Yes, steel formwork can be used in industrial construction projects. Steel formwork is known for its durability and strength, making it suitable for withstanding the heavy loads and demands of industrial construction. It is also reusable, allowing for cost savings and efficiency in large-scale projects. Additionally, steel formwork provides a smooth finish and precise alignment, ensuring high-quality and accurate construction in industrial settings.

- Q: Can steel formwork be used for water-retaining structures?

- Water-retaining structures can indeed utilize steel formwork, a flexible and long-lasting option for constructing a variety of structures. Such structures include swimming pools, water tanks, and reservoirs. The strength and stability of steel formwork make it well-suited for withstanding the pressure exerted by water. Additionally, it can be easily shaped and sized to meet the specific needs of water-retaining structures. However, it is vital to ensure the proper coating or treatment of the steel formwork to resist corrosion caused by constant water exposure. Regular maintenance and inspections are also crucial in maintaining the integrity and durability of the steel formwork within water-retaining structures.

- Q: How does steel formwork affect the overall water tightness of a structure?

- Steel formwork can have a significant impact on the overall water tightness of a structure. When used in construction, steel formwork provides a strong and rigid support system for casting concrete, enabling the creation of complex shapes and structures. However, steel formwork is not fully water tight and can allow water to penetrate through the joints, gaps, or imperfections in the formwork system. If not properly sealed or adequately reinforced, the use of steel formwork can compromise the water tightness of a structure. Water infiltration can lead to a variety of issues, including dampness, mold growth, corrosion of embedded steel reinforcement, and degradation of the concrete. These problems can weaken the structure over time, reducing its durability and lifespan. To mitigate the impact of steel formwork on water tightness, several measures can be taken. Firstly, proper jointing and sealing techniques should be employed to minimize gaps and ensure a tight fit between formwork elements. This can involve using sealants, gaskets, or waterproofing membranes to prevent water infiltration. Additionally, reinforcing the formwork with additional waterproofing layers, such as bituminous coatings or polyethylene sheets, can enhance water resistance. It is also essential to regularly inspect and maintain the formwork system to identify any potential water leakage points and address them promptly. Proper curing of the concrete is crucial to prevent shrinkage cracks that may compromise the water tightness of the structure. Applying appropriate surface treatments, such as waterproofing paints or coatings, can further enhance the water resistance of the concrete. In conclusion, while steel formwork may not be inherently water tight, its impact on the overall water tightness of a structure can be effectively managed through the implementation of proper jointing, sealing, and reinforcement techniques. By taking these precautions and conducting regular maintenance, the water tightness of the structure can be significantly improved, ensuring its long-term durability and integrity.

Send your message to us

Steel-frame Formwork system and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords