Scaffold Formwork with Timber Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

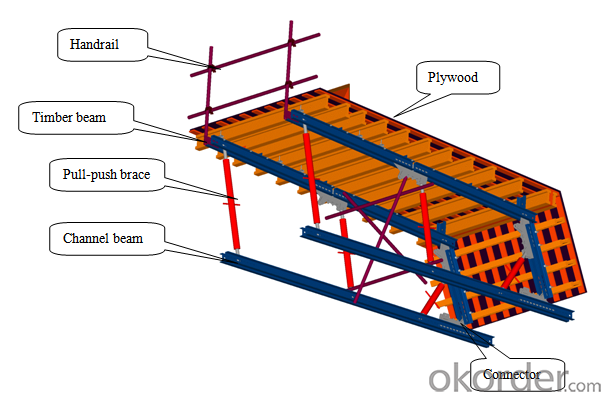

Light Weight Girder Box Formwork with Timber Beam , Channel Beam

Description:

Brief introduction

GB system-A is a kind of formwork especially for the bridge floor construction.

Competitive advantage

①. Prefabricated connection, convenient and efficient.

②. Light weight but high bearing capacity.

③. Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

Applications

- Q: How does steel formwork affect the overall constructability of the structure?

- Steel formwork can greatly enhance the constructability of a structure due to its strength, durability, and flexibility. It enables the construction process to be more efficient and precise, allowing for faster assembly and disassembly. The use of steel formwork also ensures consistent and high-quality concrete finishes, reducing the need for subsequent repairs or modifications. Additionally, steel formwork can be easily adapted to different shapes and sizes, enabling the construction of complex structures with ease. Overall, the use of steel formwork positively impacts the overall constructability of a structure by improving productivity, reducing construction time, and enhancing the final outcome.

- Q: Can steel formwork be used for bridge piers?

- Yes, steel formwork can be used for bridge piers. Steel formwork is a versatile and durable option that is suitable for constructing various types of structures, including bridge piers. It offers numerous advantages such as high strength, ease of assembly and disassembly, and flexibility in design. Steel formwork allows for precise shaping and reinforcement of the bridge piers, ensuring structural integrity and stability. Additionally, steel formwork can withstand the high loads and pressures exerted by the bridge piers during their lifespan. Therefore, steel formwork is a reliable and commonly used choice for constructing bridge piers.

- Q: How does steel formwork contribute to improved construction efficiency?

- Steel formwork contributes to improved construction efficiency in several ways. Firstly, steel formwork is known for its durability and strength. It can withstand heavy loads and extreme weather conditions, allowing construction projects to progress without delay. This means that builders can work at a faster pace and complete their tasks more efficiently. Secondly, steel formwork is reusable. Unlike traditional timber formwork, which often needs to be replaced after a few uses, steel formwork can be used multiple times, reducing the need for constant material replenishment. This not only saves time but also reduces construction costs and minimizes waste. Additionally, steel formwork offers excellent dimensional accuracy and stability. It enables precise shaping and alignment of concrete structures, ensuring that they meet the required specifications and standards. This accuracy eliminates the need for rework or adjustments, saving time and resources. Furthermore, steel formwork is easy to assemble and dismantle. Its modular design allows for quick installation and removal, reducing the time spent on formwork-related activities. This aspect is particularly beneficial when working on large-scale projects, where time is of the essence. Moreover, steel formwork provides a smooth and even finish to concrete structures. This eliminates the need for additional plastering or finishing work, further enhancing construction efficiency. Additionally, the smooth surfaces created by steel formwork are easier to clean and maintain, ensuring a longer lifespan for the structure. Finally, steel formwork offers enhanced safety for construction workers. Its strength and stability minimize the risk of accidents or collapses, providing a secure working environment. This, in turn, leads to increased productivity and efficiency on the construction site. In summary, steel formwork contributes to improved construction efficiency by providing durability, reusability, dimensional accuracy, quick assembly, smooth finishes, and enhanced safety. These factors allow construction projects to progress at a faster pace, reduce costs, and deliver high-quality structures within the desired timeframe.

- Q: How does steel formwork affect the overall project budget?

- Steel formwork can have a significant impact on the overall project budget. While steel formwork may have a higher initial cost compared to other types of formwork, such as timber or plywood, it offers several advantages that can ultimately lead to cost savings. One of the main advantages of steel formwork is its durability. Steel is a strong and long-lasting material, capable of withstanding the wear and tear of multiple uses. This means that steel formwork can be reused for numerous projects, reducing the need for frequent replacements and lowering costs in the long run. Furthermore, steel formwork allows for faster construction times. Its robustness and stability enable contractors to pour concrete at a faster rate, reducing labor costs and streamlining the construction process. Additionally, steel formwork can be easily assembled and disassembled, resulting in quicker turnaround times between projects. In terms of quality, steel formwork ensures a high level of precision and consistency in concrete structures. This can minimize the need for rework and corrections, thus reducing costs associated with fixing errors or imperfections. Moreover, steel formwork offers flexibility in design. It can be customized to fit various shapes and sizes, allowing for greater architectural freedom and creativity. This versatility can contribute to cost savings by eliminating the need for expensive and complex modifications to the formwork system. Finally, steel formwork is known for its resistance to moisture and weather conditions. Unlike timber or plywood, steel does not warp or deteriorate when exposed to moisture, which can result in cost savings by avoiding replacements or repairs due to water damage. In summary, while steel formwork may have a higher initial cost, its durability, reusability, speed, precision, flexibility, and resistance to environmental factors can lead to overall cost savings throughout the project. By considering the long-term benefits and efficiencies offered by steel formwork, project budgets can be effectively managed and optimized.

- Q: What are the different types of steel formwork systems?

- Construction projects commonly utilize various types of steel formwork systems, which serve as temporary structures or molds to support concrete during pouring and curing. Below are several types of steel formwork systems commonly used: 1. Traditional steel formwork: This prevalent system involves connecting individual steel panels using clamps or pins. These panels can be adjusted to create different shapes and sizes, and they are straightforward to assemble and disassemble. 2. Modular steel formwork: This system relies on prefabricated steel modules that are interconnected to form larger formwork assemblies. The modules are lightweight and easy to handle, making them ideal for repetitive use in projects with consistent shapes and sizes. 3. Tunnel formwork: Specifically designed for tunnel or underground structure construction, this system utilizes interconnected steel panels to create a seamless, continuous mold. It is commonly employed in large-scale infrastructure projects like subway systems or underground parking garages. 4. Climbing formwork: This system is suitable for tall structures such as high-rise buildings or towers. It comprises vertically extendable steel formwork panels that are attached to a climbing mechanism. This mechanism facilitates lifting and repositioning of the panels at each level, enabling uninterrupted construction. 5. Slip formwork: For vertical structures like walls or columns, slip formwork is utilized. It involves a moving formwork that is continuously filled with concrete as it ascends. Steel rods or cables support the formwork, allowing for the swift construction of tall and straight structures. These examples represent only a portion of the diverse steel formwork systems available. The selection of the most suitable system depends on the project's specific requirements, including structure size, shape, complexity, desired construction speed, and cost-effectiveness.

- Q: How does steel formwork prevent concrete bleeding?

- Steel formwork is a type of temporary structure that is used in construction to hold and shape the concrete until it sets and hardens. One of the advantages of using steel formwork is that it can help prevent concrete bleeding, which is the process of water separating from the mixture and rising to the surface. Steel formwork is typically designed with tight joints and smooth surfaces, which helps to create a watertight seal around the concrete. This prevents water from seeping out of the mixture and rising to the surface, reducing the occurrence of concrete bleeding. Additionally, the rigid nature of steel formwork prevents the concrete from settling or shifting during the pouring process, further minimizing the potential for bleeding. Furthermore, steel formwork offers better stability and durability compared to other types of formwork materials. Its rigid structure ensures that the formwork remains intact and maintains the desired shape during the concrete pouring process, preventing any movement that could lead to bleeding. In conclusion, steel formwork prevents concrete bleeding by providing a tight seal, stability, and a smooth surface. These features prevent water from separating from the mixture and rising to the surface, resulting in a higher quality and more visually appealing concrete finish.

- Q: How does steel formwork handle different concrete surface treatments?

- Known for its versatility and durability, steel formwork excels in managing a range of concrete surface treatments. Its robust and inflexible structure enables it to withstand the pressure and weight of such treatments without distorting or collapsing. In construction projects that involve diverse surface treatments like smooth, textured, or patterned finishes, steel formwork is commonly employed. The steel panels and frames provide a stable and sturdy surface, ensuring an even pouring and curing of the concrete. This guarantees a consistent and high-quality finish. Furthermore, steel formwork readily adapts to different types of surface treatments. For example, if a project demands a smooth finish, the steel formwork can be polished or coated with a release agent to create the desired surface. On the other hand, if a textured or patterned finish is required, the steel formwork can be specially modified or designed to incorporate the desired texture or pattern. This flexibility allows for creative and customized results. Moreover, the reusability of steel formwork makes it cost-effective and environmentally friendly. It can handle a variety of concrete surface treatments across multiple projects, consistently delivering reliable outcomes. In conclusion, steel formwork is an exceptional choice for managing different concrete surface treatments due to its strength, durability, and versatility. It can withstand the weight and pressure of diverse finishes, adapt to various surface treatments, and be reused multiple times, making it a reliable and cost-effective option in construction projects.

- Q: How does steel formwork contribute to faster construction?

- Steel formwork contributes to faster construction by offering several advantages over traditional wooden formwork. Firstly, steel formwork is highly durable and can withstand multiple uses, resulting in reduced downtime and increased productivity. Additionally, its robustness allows for faster assembly and disassembly, enabling quicker turnaround times between construction projects. The precision and accuracy of steel formwork also ensure consistent and high-quality concrete finishes, reducing the need for additional finishing work. Moreover, steel formwork is highly adaptable and can be easily modified or customized to accommodate various building designs, facilitating faster construction processes. Overall, the use of steel formwork accelerates construction timelines and enhances efficiency, thereby contributing to faster project completion.

- Q: What are the common problems encountered with steel formwork?

- There are several common problems that can be encountered with steel formwork in construction projects. One of the main issues is corrosion. Steel formwork is prone to rust and deterioration when exposed to moisture or harsh environments. This can weaken the structure and compromise its integrity, leading to potential safety hazards. Another problem is the difficulty in handling and transporting steel formwork due to its heavy weight. This can make it challenging to maneuver and assemble on-site, especially in tight spaces or high-rise buildings. The weight of the steel formwork also increases the labor and equipment costs required for installation. In addition, steel formwork may require regular maintenance to prevent damage and ensure its longevity. This includes cleaning, repairing any corrosion or dents, and applying protective coatings to prevent further deterioration. This maintenance can be time-consuming and costly, adding to the overall project expenses. Furthermore, steel formwork may not be suitable for certain construction applications. It is not easily customizable or adjustable compared to other formwork materials, such as timber or plastic. This can limit its flexibility in accommodating unique shapes or designs. Lastly, the cost of steel formwork is generally higher compared to other formwork materials. This can impact the project budget, especially for smaller or budget-constrained construction projects. Overall, while steel formwork offers durability and strength, it is important to be aware of these common problems and take necessary precautions to mitigate them. Regular maintenance, proper handling, and considering alternative formwork materials when appropriate can help address these issues and ensure a successful construction project.

- Q: How does steel formwork affect the overall construction material waste reduction?

- Steel formwork, a construction technique that employs steel panels and frames to create temporary molds or structures for pouring concrete, offers numerous advantages over traditional timber formwork. One notable advantage is its positive effect on reducing overall construction material waste. First and foremost, steel formwork boasts exceptional durability and can be reused multiple times, unlike timber formwork that often requires replacement due to wear and tear after only a few uses. Consequently, steel formwork greatly diminishes the amount of material waste generated during construction, as there is minimal need for regular replacements. Furthermore, steel formwork exhibits greater precision and accuracy compared to timber formwork, resulting in less concrete waste. The precise measurements and tight joints of steel formwork ensure the correct pouring and setting of concrete, minimizing the need for additional material to fill gaps or rectify errors. This reduction in material waste is achieved by minimizing the amount of concrete wasted during the construction process. In addition, steel formwork is highly adaptable and adjustable to various shapes and sizes, allowing for efficient and flexible use in diverse construction projects. Its versatility permits reuse for different structures or modification to meet changing requirements. This adaptability further reduces material waste, as the same formwork can be utilized for multiple projects or repurposed as needed. Moreover, steel formwork is renowned for its high strength and load-bearing capacity, enabling it to withstand substantial concrete pressure without deformation or damage. This strength allows for the construction of taller and more complex structures using steel formwork, reducing the need for additional materials such as support beams or columns. By eliminating the requirement for these extra materials, steel formwork contributes significantly to the overall reduction of construction material waste. In conclusion, steel formwork positively impacts the reduction of construction material waste through its durability, precision, adaptability, and strength. By minimizing the need for regular replacements, reducing concrete waste, allowing for reuse and adaptability, and eliminating the necessity for additional materials, steel formwork plays a vital role in promoting sustainable construction practices and reducing environmental impact.

Send your message to us

Scaffold Formwork with Timber Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords