Adjustable Arced formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

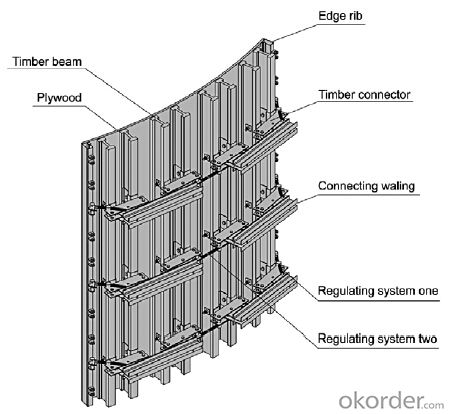

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: How does steel formwork handle formwork stripping and cleaning?

- Steel formwork is known for its durability and strength, making it highly suitable for handling formwork stripping and cleaning processes. When it comes to formwork stripping, steel formwork can easily be disassembled and removed from the concrete structure without causing damage. This is due to the inherent rigidity and stability of steel, which allows for efficient and safe stripping. Moreover, steel formwork is resistant to moisture, chemicals, and other environmental factors, making it easier to clean and maintain. After the formwork is stripped, any concrete residue or debris can be easily removed from the steel surface using appropriate cleaning techniques. This may involve the use of high-pressure water jets, scrubbing, or other cleaning agents, depending on the specific requirements. Steel formwork also offers the advantage of reusability, as it can withstand multiple uses without significant deterioration. Once the formwork is cleaned, it can be inspected for any damages or wear and tear. Any necessary repairs or replacements can be made to ensure the formwork's integrity for future use. In summary, steel formwork handles formwork stripping and cleaning efficiently due to its durability, strength, and resistance to environmental factors. Its easy disassembly, cleaning capabilities, and reusability make it a preferred choice for construction projects where formwork needs to be stripped and maintained regularly.

- Q: Can steel formwork be used for both above-water and underwater structures?

- Steel formwork can be utilized for both structures above the water surface and those submerged underwater. Its strength and durability have earned it a reputation suitable for a wide range of construction projects. When employed for structures above the water, steel formwork acts as a robust and dependable support system for casting concrete, guaranteeing the desired shape and finish are achieved. Furthermore, steel formwork is commonly employed for underwater structures due to its ability to endure the harsh conditions and pressures associated with submersion. It is engineered to be watertight and resistant to corrosion, enabling its use in casting concrete underwater. This ensures the concrete is shaped and cured correctly, resulting in structurally sound underwater constructions. In addition to its strength and durability, steel formwork also provides several advantages for both structures above the water and underwater. It is reusable, reducing construction costs and minimizing environmental impact. Moreover, steel formwork is versatile, accommodating flexible designs and adapting to diverse project requirements. Nevertheless, it is crucial to consider the specific requirements and conditions of each project when determining the suitability of steel formwork for a particular application. Factors such as water pressure, water quality, and the presence of corrosive substances should be carefully evaluated to ensure the longevity and effectiveness of the steel formwork in both structures above the water and underwater.

- Q: What materials are used in steel formwork construction?

- A sturdy and durable structure is typically created in steel formwork construction by using a combination of materials. The main material used is steel, which provides excellent strength and rigidity to support the weight and pressure of the concrete during casting. In addition to steel, other materials such as plywood or timber are used to construct the formwork panels. These panels are made of high-quality plywood or timber boards that are strong enough to bear the weight of the concrete without bending or warping. To enhance the formwork structure, steel bars or rods are strategically placed within the formwork for additional support. This prevents any deformation or collapse of the structure while pouring the concrete. Various connectors, fasteners, and accessories are also utilized in steel formwork construction. These include bolts, nuts, clamps, wedges, and pins, among others. These components securely join and hold the formwork panels and reinforcement bars together, ensuring a stable and rigid structure. Overall, steel formwork construction involves using steel, plywood or timber, reinforcement bars, and various connectors and accessories. These materials collaborate to create a robust and reliable formwork system capable of withstanding the pressures and forces exerted during the concrete casting process.

- Q: What types of concrete structures can be built using steel formwork?

- Steel formwork is versatile and can be used to construct a wide range of concrete structures. Some common examples include walls, columns, beams, slabs, foundations, and even complex structures like bridges and tunnels. The strength and durability of steel formwork make it suitable for projects of varying scales and complexities, offering a sturdy and efficient solution for creating high-quality concrete structures.

- Q: What are the common applications of steel formwork?

- Steel formwork is widely used in the construction industry for various applications. Some of the common applications of steel formwork include: 1. Concrete construction: Steel formwork is commonly used for casting concrete structures such as walls, slabs, columns, and beams. It provides a strong and rigid framework that holds the concrete in place until it hardens and gains sufficient strength. 2. High-rise buildings: Steel formwork is often used in the construction of high-rise buildings due to its durability and strength. It can withstand the pressure and weight of the concrete, ensuring the stability and safety of the structure. 3. Bridges and tunnels: Steel formwork is also used in the construction of bridges and tunnels. It allows for the precise shaping of concrete elements such as piers, abutments, and tunnel linings, ensuring the structural integrity and functionality of these infrastructure projects. 4. Industrial structures: Steel formwork finds extensive applications in the construction of industrial structures such as factories, warehouses, and power plants. It provides a robust framework that can withstand heavy loads and harsh working conditions. 5. Water retaining structures: Steel formwork is commonly used for constructing water tanks, reservoirs, and swimming pools. It ensures that the concrete is poured and cured accurately to prevent any leakage or seepage of water. 6. Architectural features: Steel formwork is also used for creating intricate architectural features such as decorative facades, curved walls, and unique shapes. Its flexibility allows for precise molding and shaping of concrete to achieve the desired design aesthetics. 7. Infrastructure projects: Steel formwork is essential for various infrastructure projects like dams, tunnels, culverts, and retaining walls. It provides a sturdy framework that supports the concrete during construction and ensures the long-term stability and functionality of these structures. Overall, steel formwork is an essential component in the construction industry, providing a reliable and efficient method for casting concrete structures in a wide range of applications. Its strength, durability, and flexibility make it a popular choice for many construction projects.

- Q: How does steel formwork handle different concrete surface cleaning methods?

- Concrete construction projects can benefit from the durability and versatility of steel formwork. When it comes to cleaning the concrete surface, steel formwork proves to be highly effective and adaptable. Pressure washing is a common method used to clean concrete surfaces. Steel formwork can withstand the force of high-pressure water jets without sustaining any damage. The smooth and non-porous nature of the steel formwork surface facilitates the removal of dirt, debris, and other unwanted materials. By utilizing pressure washing, a smooth and even finish can be achieved. Chemical cleaning is another technique employed for cleaning concrete surfaces. Steel formwork is resistant to the majority of chemicals commonly used for cleaning purposes. This allows for the usage of various cleaning agents to eliminate stubborn stains, oil, grease, and other contaminants from the concrete surface. The chemical cleaning process can be carried out without causing any harm or deterioration to the steel formwork. Manual cleaning methods may also be utilized in certain instances. Steel formwork can withstand manual scrubbing, brushing, or scraping without any issues. The strength and durability of steel make it suitable for manual cleaning methods, which may be necessary when dealing with tough stains or debris that cannot be easily removed through other means. In conclusion, steel formwork is an ideal choice for handling various concrete surface cleaning methods. Its resistance to pressure washing, chemical cleaning, and manual cleaning ensures that the concrete surface can be effectively cleaned without damaging the formwork. This allows for a clean and visually appealing finish while maintaining the structural integrity of the formwork.

- Q: Can steel formwork be used for both residential and industrial construction projects?

- Steel formwork is suitable for both residential and industrial construction projects. It is a versatile and durable solution that can withstand the demands of various construction projects. It offers a high level of strength and stability, making it suitable for small-scale residential projects as well as large-scale industrial projects. Furthermore, steel formwork has the added benefit of being reusable, which can help save costs and reduce waste in construction projects. It is also easy to assemble and disassemble, making it a practical choice for different types of projects. In conclusion, steel formwork is a reliable and efficient option for both residential and industrial construction projects.

- Q: Can steel formwork be used for both vertical and horizontal concrete structures?

- Indeed, both vertical and horizontal concrete structures can benefit from the utilization of steel formwork. The versatility of steel formwork grants the ability to effortlessly modify and construct diverse shapes and sizes for varying structures. This resource supplies robust reinforcement, stability, and longevity, thus rendering it appropriate for vertical walls and horizontal slabs alike. Moreover, steel formwork boasts exceptional accuracy in dimensions, guaranteeing meticulous concrete placement and alignment. Furthermore, steel formwork's reusability renders it an economically efficient choice for construction endeavors mandating recurrent employment of formwork systems.

- Q: Can steel formwork be used for both straight and curved concrete walls?

- Yes, steel formwork can be used for both straight and curved concrete walls. Steel formwork is versatile and can be easily bent and adjusted to create curved walls of various shapes and sizes. It provides strong support and stability, allowing for the construction of both straight and curved walls with precision and accuracy. Additionally, steel formwork is durable and reusable, making it a cost-effective option for projects that require both straight and curved concrete walls.

- Q: Can steel formwork be used for projects with high concrete durability demands?

- Yes, steel formwork can be used for projects with high concrete durability demands. Steel formwork is known for its strength, durability, and longevity, making it suitable for demanding construction projects. It can withstand heavy loads and provide the necessary support for the concrete during the curing process. Steel formwork also offers excellent dimensional stability, ensuring the accuracy and consistency of the concrete structure. Additionally, steel formwork can be reused multiple times, reducing waste and project costs. However, it is important to ensure proper maintenance and corrosion protection of the steel formwork to maximize its durability and ensure long-term performance.

Send your message to us

Adjustable Arced formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords