Steel-frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

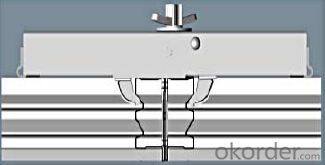

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for structures with high corrosion resistance requirements?

- No, steel formwork may not be suitable for structures with high corrosion resistance requirements. Steel is prone to corrosion when exposed to moisture and certain environmental conditions. Over time, this corrosion can weaken the formwork and compromise the structural integrity of the concrete. To ensure high corrosion resistance, alternative materials such as fiberglass, aluminum, or plastic formwork may be more appropriate. These materials are resistant to corrosion and can withstand harsh conditions, making them suitable for structures with high corrosion resistance requirements.

- Q: What is the cost of steel formwork compared to other types of formwork?

- The cost of steel formwork is generally higher compared to other types of formwork due to its durability, reusability, and strength. While it may have a higher upfront cost, it provides long-term cost benefits over time as it can be used multiple times and requires minimal maintenance.

- Q: How does steel formwork affect the speed of construction?

- The numerous advantages of steel formwork greatly enhance the speed of construction. Firstly, its high durability allows for multiple pours without the need for replacement or repair, eliminating downtime associated with timber formwork. In addition, steel formwork is easily assembled and disassembled due to its modular nature, reducing overall construction time. This is particularly beneficial for time-sensitive large-scale projects. Furthermore, steel formwork ensures precise and uniform construction, eliminating excessive rework and adjustments. This saves both time and resources. Moreover, steel formwork can handle high concrete pressures, allowing for faster pouring and setting of concrete. This eliminates the need to wait for the formwork to fully cure before proceeding to the next pour, resulting in faster construction cycles and increased productivity. Lastly, steel formwork is compatible with various construction techniques and can be easily adapted to suit different project requirements. It can be used for a wide range of applications, enabling faster construction of diverse building elements. Overall, steel formwork significantly speeds up the construction process by offering durability, ease of use, dimensional accuracy, and compatibility with different construction techniques. Its ability to handle high concrete pressures and its modular nature contribute to faster construction cycles and increased productivity, making it an ideal choice for efficient construction projects.

- Q: Are there any limitations to the size of concrete pours with steel formwork?

- Yes, there are limitations to the size of concrete pours with steel formwork. One limitation is the weight and size of the steel formwork itself. Steel formwork is typically heavy and can be difficult to maneuver, especially in large sizes. This can make it challenging to handle and place the formwork for larger concrete pours. Another limitation is the need for additional supports and bracing for larger pours. Steel formwork may require additional reinforcement and bracing to prevent it from bending or collapsing under the weight of the concrete. This can increase the complexity and cost of the formwork installation. Additionally, the size and weight of the concrete itself can be a limitation. Large concrete pours can generate significant heat during the curing process, which can cause thermal cracking and other durability issues. Steel formwork may not be able to withstand the high temperatures and pressures generated by large concrete volumes, leading to formwork failure or deformation. Furthermore, the logistics and transportation of larger concrete pours can be challenging. The availability of concrete trucks and pumps capable of delivering large volumes of concrete to the construction site can be limited. This can result in delays and increased costs for larger pours. Overall, while steel formwork can be used for a wide range of concrete pours, there are limitations to consider when it comes to the size and complexity of the project. It is important to assess the specific requirements and constraints of each project to determine the feasibility and suitability of using steel formwork for larger concrete pours.

- Q: How does steel formwork differ from other types of formwork?

- There are several ways in which steel formwork differs from other types of formwork. To begin with, steel formwork is renowned for its durability and long lifespan. While wooden or plastic formwork often needs to be replaced frequently due to wear and tear, steel formwork can withstand heavy use and be reused multiple times. As a result, it is a cost-effective option in the long term, as it eliminates the need for constant replacements. Furthermore, steel formwork provides a higher level of precision and accuracy in construction. Its rigid structure ensures that the concrete is poured and cured in the desired shape and dimensions. This is particularly important in projects that require high-quality finishes or intricate architectural designs. Moreover, steel formwork offers excellent structural support. It can endure the pressure exerted by wet concrete without deforming or collapsing, thus ensuring the stability and safety of the construction process. This is especially vital in large-scale projects or situations involving high volumes of concrete. In addition, steel formwork is versatile and easily customizable to meet specific project requirements. It can be swiftly assembled and disassembled, enabling quick and efficient construction processes. Steel formwork can also be adjusted to accommodate various shapes and sizes, making it suitable for a wide range of construction projects. Lastly, steel formwork is highly resistant to weather conditions and environmental factors. Unlike wooden formwork, which may warp or deteriorate when exposed to moisture, steel formwork remains stable and unaffected by changes in temperature or humidity. Consequently, it is suitable for both indoor and outdoor construction projects. In conclusion, steel formwork distinguishes itself from other formwork types due to its durability, precision, structural support, versatility, and resilience to environmental factors. It offers numerous advantages that make it a preferred choice for many construction projects.

- Q: What are the considerations when designing steel formwork for industrial facilities?

- Several important considerations need to be taken into account when designing steel formwork for industrial facilities. These considerations encompass: 1. Load-bearing capacity: The steel formwork must be designed to withstand the weight and load of heavy machinery and equipment commonly found in industrial facilities. It should provide structural stability and ensure safety while supporting the machinery's weight. 2. Durability: The steel formwork needs to withstand the harsh conditions prevalent in industrial facilities, such as temperature fluctuations, exposure to chemicals or corrosive substances, and heavy usage. Its design should prioritize longevity and minimal maintenance requirements to ensure cost-effectiveness. 3. Flexibility and adaptability: Industrial facilities often undergo changes, upgrades, or modifications over time. Thus, the steel formwork should be designed to be easily modified or expanded, considering future machinery or equipment relocation or reconfiguration. 4. Safety: Safety is a crucial aspect to consider when designing steel formwork for industrial facilities. Incorporating safety features like guardrails, non-slip surfaces, and adequate lighting is important to prevent accidents or injuries. Adhering to relevant safety codes and standards is also necessary for compliance. 5. Ease of construction and dismantling: The steel formwork should be designed for effortless assembly and disassembly. This not only saves construction time but also enables the formwork's efficient reuse in future projects. Modular designs or prefabricated components can facilitate easier construction and dismantling processes. 6. Cost-effectiveness: Designing steel formwork for industrial facilities should also prioritize cost-effectiveness. This involves optimizing material usage, minimizing waste, and considering long-term maintenance and operational costs. Striking a balance between the initial investment and the expected lifespan and benefits of the formwork is essential in achieving the most cost-effective solution. In summary, designing steel formwork for industrial facilities necessitates careful consideration of load-bearing capacity, durability, flexibility, safety, ease of construction, and cost-effectiveness. Addressing these considerations ensures that the formwork meets the specific requirements of industrial applications, providing a reliable and efficient solution for construction projects.

- Q: Is steel formwork suitable for projects with tight deadlines?

- Yes, steel formwork is suitable for projects with tight deadlines. Steel formwork is known for its durability, strength, and versatility, allowing for faster construction processes. It can be assembled and disassembled quickly, enabling efficient workflow and reducing construction time. Additionally, steel formwork offers high-quality finishes, ensuring the timely completion of projects without compromising on the desired aesthetic appeal.

- Q: How does steel formwork handle construction joints?

- Steel formwork handles construction joints by providing a strong and rigid framework that can be easily adjusted and aligned to accommodate the formation of joints. It allows for precise placement and alignment of the formwork, ensuring that the joints are properly supported and reinforced. Additionally, steel formwork can be easily dismantled and reassembled, making it efficient for handling construction joints during the entire construction process.

- Q: What are the different types of tie systems used in steel formwork?

- There are several types of tie systems used in steel formwork, including through ties, external ties, and snap ties. Through ties are typically used for large wall formwork, where steel rods are inserted through the formwork and secured with nuts and plates on both sides. External ties are used for smaller wall panels, where steel rods are attached to the exterior of the formwork and anchored to the ground or surrounding structures. Snap ties are commonly used for column formwork, where metal or plastic cones are inserted into the formwork and secured with a metal snap tie. These tie systems provide stability and strength to the steel formwork during concrete pouring and curing.

- Q: How does steel formwork affect the overall safety of a building project?

- Steel formwork can greatly enhance the overall safety of a building project due to its durability, strength, and stability. It provides a solid and secure framework for concrete placement, ensuring proper alignment and support during the construction process. This reduces the risk of structural failures, collapses, or accidents, thereby enhancing the safety of workers and the overall project. Additionally, steel formwork is fire-resistant, which further contributes to the safety of the building as it can withstand high temperatures and prevent the spread of fire.

Send your message to us

Steel-frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords