Steel-frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

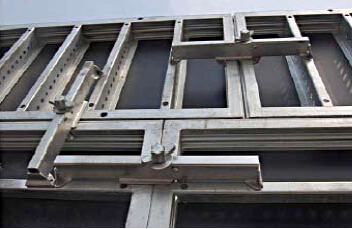

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

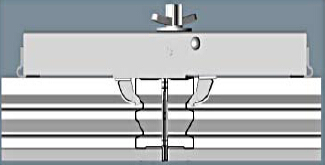

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork contribute to the sustainability of the construction industry?

- The sustainability of the construction industry is enhanced by steel formwork in various ways. To begin with, steel formwork is remarkably robust and long-lasting. Unlike traditional wooden formwork, which requires frequent replacement, steel formwork can be reused multiple times. This reduces the need for new materials and minimizes waste, benefiting construction companies financially and reducing the demand for timber, thus lessening the industry's environmental impact. Furthermore, steel formwork is more efficient and time-saving compared to other types of formwork. Its usage enables faster assembly and disassembly, resulting in reduced construction time and costs. This increased efficiency leads to lower energy consumption and carbon emissions, thereby contributing to the sustainability of the construction process. Additionally, steel formwork offers design flexibility and adaptability. It can be easily employed in the construction of complex structures, eliminating the need for additional materials and resources. This adaptability not only reduces construction waste but also enhances the sustainability of the industry. Moreover, steel formwork possesses a high load-bearing capacity, enabling the construction of taller and stronger structures. This reduces the amount of materials required to achieve the desired structural integrity, resulting in decreased resource consumption and waste generation. The ability to construct more durable buildings also contributes to the long-term sustainability of the construction industry by reducing the frequency of repairs or replacements. Lastly, steel formwork is recyclable. At the end of its lifespan, it can be efficiently and easily recycled, reducing the need for new steel production and minimizing the environmental impact associated with its extraction and manufacturing. In conclusion, the durability, efficiency, flexibility, load-bearing capacity, and recyclability of steel formwork contribute to the sustainability of the construction industry. By reducing waste, energy consumption, and carbon emissions, it promotes a more sustainable and responsible approach to construction projects.

- Q: Can steel formwork be used for concrete structures in corrosive environments?

- No, steel formwork should not be used for concrete structures in corrosive environments as it may lead to corrosion of the steel and compromise the integrity of the structure.

- Q: What types of concrete structures can be built using steel formwork?

- Steel formwork is a versatile construction tool that has the capability to build a variety of concrete structures. Some examples of common structures that can be created using steel formwork are: 1. Walls: Steel formwork can be utilized to construct both retaining walls and load-bearing walls. It provides the necessary support to hold the concrete in place until it sets and gains its strength. Steel formwork allows for the construction of walls with different shapes and sizes, such as straight, curved, or inclined walls. 2. Columns: For constructing columns of varying heights and diameters, steel formwork is the ideal choice. It offers a strong and stable framework to hold the concrete in place while it cures. Steel formwork can be easily adjusted to accommodate various column dimensions, making it suitable for both small and large-scale construction projects. 3. Beams and Slabs: Beams, which are horizontal structural members that support the structure above, and slabs, which form the floors or roofs of a building, can also be constructed using steel formwork. Steel formwork allows for the construction of beams and slabs with different shapes and sizes, including rectangular, circular, or even curved configurations. 4. Bridges and Tunnels: Bridges and tunnels commonly rely on steel formwork during construction. It enables the creation of complex structural elements with high precision and accuracy. Steel formwork systems are easily transportable and can be assembled on-site, making them an efficient choice for bridge and tunnel construction projects. 5. Staircases: Steel formwork can also be used to build staircases with various configurations, such as straight flights, spiral stairs, or helical stairs. It provides the necessary support to create the desired shape and geometry of the staircase. Steel formwork ensures the structural integrity of the staircase while the concrete sets and hardens. In summary, steel formwork is a flexible and durable solution for constructing a wide range of concrete structures. Its adaptability, strength, and ease of use make it an ideal choice for various construction projects, including residential buildings and large-scale infrastructure developments.

- Q: How does steel formwork contribute to the overall durability of the concrete structure?

- Steel formwork contributes to the overall durability of a concrete structure in several ways. Firstly, steel formwork provides a strong and rigid framework for pouring and shaping the concrete. This ensures that the concrete is properly supported during the curing process, preventing any deformation or collapse that could compromise the structure's integrity. Additionally, steel formwork is highly resistant to the corrosive effects of concrete, which contains alkaline substances that can slowly erode other materials over time. This resistance to corrosion ensures that the formwork remains stable and intact throughout the construction process, maintaining the shape and dimensions of the concrete elements. Moreover, steel formwork allows for precise and accurate construction, resulting in a concrete structure with consistent dimensions and smooth finishes. This precision minimizes the chances of structural weaknesses or flaws in the concrete, enhancing its overall durability. Furthermore, steel formwork is reusable, making it a cost-effective option for construction projects. By using steel formwork multiple times, the overall durability of the concrete structure is improved as the formwork retains its strength and stability over numerous applications. In conclusion, steel formwork plays a crucial role in enhancing the overall durability of a concrete structure. Its strength, resistance to corrosion, precision, and reusability ensure that the concrete is properly supported, accurately constructed, and able to withstand external forces, contributing to a long-lasting and robust structure.

- Q: How does steel formwork affect the overall cost of concrete construction?

- Steel formwork can have a significant impact on the overall cost of concrete construction. While it may initially be more expensive to invest in steel formwork compared to traditional wood formwork, the long-term benefits and cost savings outweigh the initial investment. One of the main advantages of steel formwork is its durability and reusability. Unlike wood formwork, steel formwork can be used multiple times, reducing the need for frequent replacement and lowering material costs. Additionally, steel formwork is resistant to warping, shrinking, and swelling, ensuring that the concrete structure maintains its intended shape and dimensions, which can save both time and money in terms of rework and adjustments. The strength and stability of steel formwork also contribute to cost savings. Steel formwork can withstand higher concrete pressures, allowing for taller and more complex structures to be constructed. This eliminates the need for extra reinforcements or additional support systems, decreasing the amount of materials required and minimizing labor costs. Furthermore, steel formwork provides a smooth and even surface finish, reducing the need for additional surface treatments or finishes. This not only saves costs on materials but also speeds up construction time, as there is no need for extensive surface preparation. Another cost-saving factor is the ease of assembly and disassembly associated with steel formwork. The efficient design and standardized components of steel formwork make it quick and easy to install and dismantle, reducing labor costs and improving overall productivity. In summary, while steel formwork may have a higher initial cost, its durability, reusability, strength, stability, and ease of use can lead to significant cost savings in terms of material, labor, and time. The overall efficiency and longevity of steel formwork make it a cost-effective choice for concrete construction projects.

- Q: Concrete, reinforcing steel for the labor price? 18 storey elevator apartment with a layer of underground carpentry, concrete, steel artificial price. (to the workers to do the Contractor) the problem added: steel, including the production and installation of a full set of artificial ha, concrete is mixed business. Template carpenter??? Concrete with nails??? Steel??? Including machine...Is the area of 10000 square meters of construction area template?How many tons of steel?

- The main body of the wall and inside and outside the powder to the construction area of 70/M2 (including small equipment)10000 square meters of construction area by the consideration of the template to pay two, the need for a template of 10000 square metersThere are about 6~700 tons of rebar

- Q: How does steel formwork affect the overall sustainability of a concrete structure?

- Steel formwork can have a significant impact on the overall sustainability of a concrete structure. Firstly, steel formwork is reusable, which means that it can be used for multiple construction projects, reducing the need for additional materials and minimizing waste. This reusability also helps reduce the environmental impact associated with the production and disposal of formwork materials. Additionally, steel formwork is durable and robust, which ensures that it can withstand repeated use without compromising its structural integrity. This durability extends the lifespan of the formwork, reducing the need for frequent replacements and further reducing waste generation. Furthermore, steel formwork provides superior strength and stability, allowing for the construction of concrete structures with greater precision and efficiency. This facilitates the use of less concrete, reducing the overall carbon footprint of the structure. Additionally, the use of steel formwork can result in faster construction times, minimizing energy consumption and reducing the project's environmental impact. Moreover, steel formwork allows for greater flexibility in design and construction techniques, enabling the creation of more sustainable structures. It can be easily customized to fit various shapes and sizes, optimizing the use of space and reducing material wastage. This flexibility also allows for the integration of sustainable features such as energy-efficient insulation, green roofs, or rainwater harvesting systems. In summary, steel formwork positively impacts the overall sustainability of a concrete structure through its reusability, durability, strength, and flexibility. By reducing waste generation, minimizing the use of concrete, and enabling sustainable design options, steel formwork contributes to the creation of more environmentally-friendly and efficient structures.

- Q: What are the different types of steel used in formwork construction?

- Formwork construction utilizes various types of steel, each possessing distinct characteristics and applications. 1. Mild Steel: The most frequently employed steel in formwork construction, mild steel offers affordability, availability, and ease of handling. It is suitable for numerous formwork applications, boasting commendable strength and durability. 2. High Tensile Steel: Distinguishing itself from mild steel, high tensile steel exhibits superior strength and tensile properties, rendering it ideal for robust formwork structures. Its ability to resist bending and deformation under heavy loads makes it particularly fitting for extensive construction projects. 3. Reinforcing Steel: Also referred to as rebar, reinforcing steel reinforces concrete structures in formwork construction. Typically composed of carbon steel, it comes in various grades and sizes. Reinforcing steel is employed to enhance concrete's tensile strength, diminish cracking, and prevent structural failure. 4. Stainless Steel: When prioritizing resistance to corrosion, formwork construction turns to stainless steel. This material excels in environments with harsh conditions or exposure to corrosive substances. Its exceptional resistance to corrosion results in a long-lasting and durable choice for formwork construction. 5. Alloy Steel: Utilized in formwork construction for its augmented properties, alloy steel combines with other elements to enhance its characteristics. This type of steel is commonly employed for its high strength, toughness, and resistance to wear and tear. Formwork systems requiring outstanding performance and durability often rely on alloy steel to withstand substantial loads. Ultimately, the selection of steel for formwork construction hinges upon project-specific requirements, encompassing load-bearing capacity, durability, and corrosion resistance. The appropriate type of steel must be chosen to guarantee the safety and longevity of the formwork structure.

- Q: How does steel formwork affect the overall energy efficiency of a building?

- The overall energy efficiency of a building can be significantly impacted by steel formwork. Firstly, the durability and longevity of steel formwork are well-known. This means that the steel can be reused multiple times after the concrete is poured and the formwork is removed, reducing the need for new materials. The reuse of steel formwork decreases the energy and resources required for manufacturing new formwork, thus decreasing the embodied energy of the building. Additionally, steel formwork provides better insulation properties compared to traditional timber formwork. This improved insulation helps to minimize heat transfer through the building envelope, which in turn reduces the energy consumption needed for heating and cooling. The thermal mass of steel formwork also aids in regulating temperatures within the building, resulting in increased energy efficiency. Furthermore, steel formwork allows for precise and accurate construction, leading to tighter joints and fewer air leaks. This improves the overall air tightness of the building, reducing the infiltration of outside air and enhancing the energy efficiency of the HVAC system. The reduced air leakage also contributes to better indoor air quality by preventing the entry of pollutants and allergens. Moreover, steel formwork facilitates the integration of other sustainable technologies, such as renewable energy systems and advanced insulation materials. The strength and flexibility of steel enable the incorporation of larger windows, maximizing natural light and reducing the need for artificial lighting during the day. In conclusion, steel formwork has positive effects on the energy efficiency of a building by reducing embodied energy, improving insulation, enhancing air tightness, and enabling the integration of sustainable technologies. By opting for steel formwork, builders and developers can contribute to the long-term sustainability and energy efficiency of the built environment.

- Q: What are the different types of steel formwork joint solutions?

- There are several types of steel formwork joint solutions used in construction projects. These joint solutions are designed to provide stability, strength, and flexibility to the formwork system. Some of the commonly used types of steel formwork joint solutions include: 1. Butt Joint: This is a simple and commonly used joint where two steel formwork panels are joined together by aligning the edges and securing them with bolts or clamps. Butt joints are easy to assemble and disassemble, making them suitable for various construction applications. 2. Corner Joint: As the name suggests, corner joints are used when two steel formwork panels meet at a corner. These joints are typically formed by overlapping the panels and securing them with bolts or clamps. Corner joints provide stability and reinforcement to the formwork system, particularly in areas where walls or columns are being constructed. 3. T-Joint: T-joints are used when three steel formwork panels meet at one point. This joint solution is formed by overlapping the panels and securing them with bolts or clamps. T-joints are commonly used in construction projects where complex shapes or structures are being built. 4. L-Joint: L-joints are similar to T-joints but involve only two steel formwork panels meeting at right angles. These joints are formed by overlapping the panels and securing them with bolts or clamps. L-joints are used to create corners in formwork systems, such as when constructing columns or beams. 5. Hinged Joint: Hinged joints are used when there is a need for flexibility in the formwork system. These joints allow the formwork panels to pivot or rotate, accommodating changes in shape or position. Hinged joints are commonly used in curved or irregular structures where rigid joints may not be suitable. 6. Adjustable Joint: Adjustable joints are used when there is a requirement for height or width adjustment in the formwork system. These joints allow for easy modification of the formwork dimensions to accommodate changes in design or construction requirements. Adjustable joints are particularly useful in projects that involve varying dimensions or levels. It is important to select the appropriate steel formwork joint solution based on the specific construction requirements and structural design. Proper installation and reinforcement of these joints ensure the stability and integrity of the formwork system, which is crucial for the successful execution of the construction project.

Send your message to us

Steel-frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords