Steel-Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

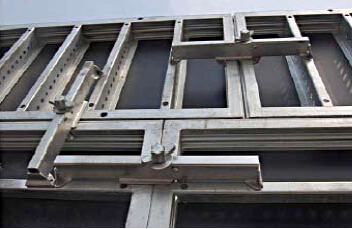

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

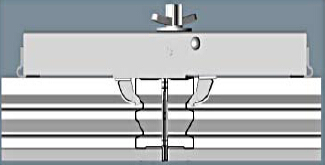

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork handle formwork stripping and repositioning?

- Steel formwork is an option that is highly durable and versatile for the handling of formwork stripping and repositioning. It is designed to withstand the pressure exerted during the concrete pouring process and can easily manage the removal of the formwork once the concrete has set. When it comes to the removal of formwork, steel formwork offers several advantages. Firstly, it ensures a high-quality end result by providing a smooth surface finish to the concrete. The steel panels are typically coated with a protective layer, preventing concrete from sticking to the formwork and making stripping easier. The steel formwork system is engineered to facilitate quick and efficient formwork removal. This is achieved through the use of various mechanisms such as wedge clamps, pins, or hooks, which securely hold the formwork panels in place during the pouring process. Once the concrete has gained sufficient strength, these mechanisms can be easily released, allowing for smooth and effortless stripping of the formwork. Furthermore, steel formwork can be easily repositioned and reused for multiple construction projects. The modular design of steel panels allows for flexibility in adjusting the formwork to different dimensions and shapes. This reusability significantly reduces the overall cost of formwork, making it a cost-effective solution for construction projects. In addition, steel formwork provides excellent strength and stability, ensuring the integrity of the structure throughout the formwork stripping and repositioning process. This is particularly crucial in high-rise or complex structures where the formwork must withstand significant loads and pressures. In conclusion, steel formwork is a dependable and efficient choice for handling formwork stripping and repositioning. Its durability, ease of use, and adaptability make it the preferred option for construction projects of various sizes and complexities.

- Q: How does steel formwork contribute to the sustainability of the construction industry?

- Steel formwork contributes to the sustainability of the construction industry in several ways. Firstly, steel formwork is highly durable and long-lasting. Unlike traditional wooden formwork, which often needs to be replaced after a few uses, steel formwork can be reused multiple times, reducing the need for new materials and minimizing waste. This not only saves money for construction companies but also reduces the environmental impact of the industry by reducing the demand for timber. Secondly, steel formwork is more efficient and time-saving compared to other types of formwork. The use of steel allows for faster assembly and disassembly, reducing construction time and costs. This efficiency translates into reduced energy consumption and lower carbon emissions, thereby contributing to the sustainability of the construction process. Moreover, steel formwork offers flexibility and adaptability in design, allowing for the construction of complex structures with ease. This versatility reduces the need for additional materials and resources, as the same formwork can be used for various projects. This adaptability also minimizes construction waste, further enhancing the sustainability of the industry. Additionally, steel formwork has a high load-bearing capacity, enabling the construction of taller and stronger structures. This means that fewer materials are required to achieve the same structural integrity, reducing resource consumption and waste generation. The ability to construct more durable buildings also contributes to the long-term sustainability of the construction industry by reducing the need for frequent repairs or replacements. Lastly, steel formwork is recyclable. At the end of its lifespan, steel formwork can be easily and efficiently recycled, reducing the demand for new steel production and minimizing the environmental impact associated with its extraction and manufacturing. In conclusion, steel formwork contributes to the sustainability of the construction industry through its durability, efficiency, flexibility, load-bearing capacity, and recyclability. Its ability to reduce waste, energy consumption, and carbon emissions makes it an environmentally-friendly choice for construction projects, promoting a more sustainable and responsible construction industry.

- Q: What are the different types of sealing systems used with steel formwork?

- There are primarily three types of sealing systems used with steel formwork: mechanical seals, chemical seals, and hydraulic seals. Mechanical seals involve using gaskets, rubber strips, or other mechanical devices to create a tight seal between the formwork components. Chemical seals involve applying chemical sealants or adhesives to fill any gaps or joints in the formwork, ensuring a watertight seal. Hydraulic seals use hydraulic pressure to create a seal, typically achieved through the use of specialized hydraulic clamps or seals. Each sealing system has its advantages and disadvantages depending on the specific requirements of the construction project.

- Q: Can steel formwork be used for water tanks or swimming pools?

- Yes, steel formwork can be used for water tanks or swimming pools. Steel formwork is highly durable and can withstand the pressure exerted by the water. It provides a strong structure for the tank or pool, ensuring stability and longevity. Additionally, steel formwork allows for flexibility in design and can be easily customized to meet specific project requirements.

- Q: Can steel formwork be used for water storage tanks?

- No, steel formwork is not suitable for water storage tanks as it is not water-resistant and may corrode over time.

- Q: What are the different finishes that can be achieved with steel formwork?

- The desired aesthetic and functional requirements of a project determine the various finishes that can be achieved with steel formwork. 1. To achieve a clean and seamless appearance, smooth surfaces can be created with steel formwork. This finish is commonly preferred for architectural applications and high-end buildings. 2. Textured finishes can be achieved by incorporating patterns, designs, or textures onto the steel formwork or using form liners. These finishes add visual interest and can mimic natural materials like stone, wood, or brick. 3. Exposing the aggregate in the concrete surface creates a rough and textured appearance, showcasing the natural beauty of the aggregates. This finish is often used decoratively in applications like sidewalks, driveways, and patios. 4. By using rubber stamps with steel formwork, stamped finishes with intricate patterns and designs like brick, tile, or stone imprints can be created. These finishes are commonly used to add decorative elements to concrete floors, walls, or pavements. 5. A polished finish can be achieved by grinding and polishing the concrete surface, resulting in a smooth, glossy, and reflective surface. This finish is commonly used in commercial and residential buildings, as well as in high-traffic areas that require durability and low maintenance. In summary, steel formwork offers a versatile and flexible solution for achieving different finishes in concrete construction. The choice of finish depends on specific design requirements, project goals, and desired aesthetic outcomes.

- Q: How does steel formwork contribute to the overall moisture resistance of the structure?

- Steel formwork contributes to the overall moisture resistance of a structure in several ways. Firstly, steel formwork is designed to be highly durable and resistant to corrosion. This means that it can withstand exposure to moisture without deteriorating or losing its structural integrity. Additionally, steel formwork is constructed with tight joints and connections, minimizing the potential for water infiltration. Unlike traditional timber formwork, steel formwork does not shrink or warp when exposed to moisture, ensuring that there are no gaps or openings that would allow water to seep into the structure. Furthermore, steel formwork is often coated with protective finishes, such as epoxy or galvanized coatings, which provide an extra layer of moisture resistance. These coatings act as a barrier, preventing water from penetrating the steel and reaching the concrete structure. By providing a strong, watertight enclosure during the construction process, steel formwork helps to prevent moisture from entering the structure. This is particularly important for structures that will be exposed to external elements, such as bridges or buildings located in humid or rainy climates. Overall, steel formwork's durability, tight joints, and protective coatings contribute to the overall moisture resistance of a structure, ensuring that it remains structurally sound and free from water damage.

- Q: How does steel formwork affect the overall fire resistance of the structure?

- Steel formwork does not directly affect the overall fire resistance of a structure. Fire resistance of a building mainly depends on the materials used for the structural elements such as columns, beams, and floors. Steel formwork, which is used as a temporary mold or support during construction, is not a structural element itself. However, steel formwork can indirectly influence the fire resistance of a structure in two ways. Firstly, if the steel formwork is left in place after construction, it can act as an additional layer of protection against fire. Steel has a high melting point and can withstand high temperatures for a longer duration compared to other materials. Therefore, if the formwork is left in place, it can provide some level of fire resistance to the structure. Secondly, the use of steel formwork can affect the fire resistance of the structure by influencing the construction process. The formwork system should be installed and secured properly to ensure the structural elements are correctly positioned and aligned. Properly installed formwork helps in achieving accurate dimensions and proper reinforcement placement, which are crucial for maintaining the fire resistance of a structure. In summary, steel formwork itself does not have a direct impact on the fire resistance of a structure. However, if the formwork is left in place after construction, it can provide some additional fire resistance. Moreover, the proper installation and use of steel formwork can indirectly contribute to the fire resistance of a structure by ensuring accurate construction and reinforcement placement.

- Q: Can steel formwork be used for precast concrete columns?

- Yes, steel formwork can be used for precast concrete columns. Steel formwork offers several advantages for precast concrete column construction. Firstly, steel formwork is durable and can withstand the pressure exerted by the concrete during the casting process. This ensures that the formwork maintains its shape and integrity, resulting in accurately shaped columns. Additionally, steel formwork provides a smooth and consistent surface finish to the concrete columns. This is important for aesthetic purposes, as well as ensuring that the columns meet the required specifications. Steel formwork also allows for easy demolding and reusability, which can significantly reduce construction time and cost. Furthermore, steel formwork can be easily customized and adapted to different column designs and dimensions. This flexibility makes it suitable for a wide range of precast concrete column applications, including various shapes and sizes. However, it is important to consider certain factors when using steel formwork for precast concrete columns. The weight of the steel formwork should be adequately supported to prevent any deformation or collapse during the casting process. Additionally, proper precautions should be taken to prevent rusting or corrosion of the steel formwork, as this can affect the quality of the concrete. Overall, steel formwork is a viable option for precast concrete column construction, offering durability, flexibility, and ease of use.

- Q: What are the considerations when selecting the appropriate formwork system for a project?

- When selecting the appropriate formwork system for a project, there are several considerations that need to be taken into account. These considerations include the type of structure being constructed, the required finish of the concrete, the project timeline, the budget, and the available resources. The type of structure being constructed is a crucial factor in selecting the formwork system. Different structures, such as walls, columns, or slabs, require different types of formwork systems to ensure proper support and stability. It is important to understand the specific requirements of the structure before choosing a formwork system. The required finish of the concrete also plays a role in selecting the appropriate formwork system. If a smooth and seamless finish is desired, a formwork system that can provide the necessary level of detail and precision must be chosen. On the other hand, if a rough finish is acceptable, a simpler and less expensive formwork system may be sufficient. The project timeline is another key consideration. Some formwork systems are quicker and easier to assemble and dismantle, which can help speed up the construction process. Additionally, the availability of the formwork system and the lead time required for procurement should also be considered to ensure that it aligns with the project schedule. Budget is always an important consideration in any construction project. Formwork systems vary in cost, and it is essential to select a system that fits within the project's budget. It is also important to consider the long-term cost implications, such as maintenance and reusability, to determine the overall cost-effectiveness of the chosen formwork system. Lastly, the available resources, including labor and equipment, should be taken into account when selecting a formwork system. Some systems may require specialized labor or equipment, which may not be readily available or may require additional costs. Considering the resources at hand will help determine the feasibility and practicality of a particular formwork system. In conclusion, selecting the appropriate formwork system for a project requires careful consideration of the type of structure, required concrete finish, project timeline, budget, and available resources. By evaluating these factors, project managers can make informed decisions that will contribute to the successful completion of the project.

Send your message to us

Steel-Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords