Steel Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

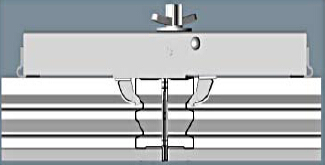

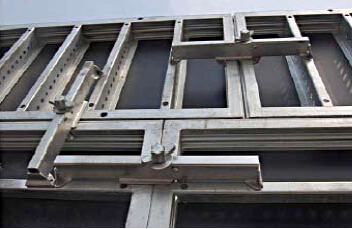

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the different types of finishes applied to steel formwork surfaces?

- Steel formwork surfaces can be enhanced with various finishes, each serving a specific purpose. These finishes aim to improve the appearance, durability, and performance of the steel formwork. Here are some commonly used finishes: 1. Galvanized Finish: A popular choice for outdoor or high-moisture environments, this finish involves coating the steel with a layer of zinc, offering excellent corrosion resistance. 2. Powder Coating: In this process, a dry powder is electrostatically applied to the steel surface and then cured under heat. The result is a hard, long-lasting finish that resists chipping, scratching, and fading. Powder coatings come in a wide range of colors and textures. 3. Paint Finish: Paint finishes are commonly used to enhance the aesthetics of steel formwork. They provide a smooth, uniform appearance and can be customized to match specific color requirements. Paint finishes also offer some protection against corrosion and weathering. 4. Epoxy Coating: Known for their chemical resistance and durability, epoxy coatings are often used in industrial applications where the steel formwork may be exposed to chemicals, acids, or solvents. These coatings also provide good adhesion and resistance to abrasion. 5. Anodized Finish: The anodizing process forms a layer of aluminum oxide on the steel formwork surface, resulting in enhanced corrosion resistance and a decorative appearance. Anodized finishes are commonly used in architectural applications. 6. Stainless Steel Finish: In certain steel formwork applications, a stainless steel finish may be preferred. Stainless steel is naturally resistant to corrosion and has a sleek, modern appearance. It is often used in environments with high humidity or chemical exposure. These examples highlight the different finishes available for steel formwork surfaces. The choice of finish depends on factors such as the formwork's intended use, desired aesthetics, and environmental conditions it will face.

- Q: Are there any specific quality control measures for steel formwork installation?

- Yes, there are specific quality control measures for steel formwork installation. These quality control measures are put in place to ensure that the steel formwork is installed correctly and meets the required standards. One of the key quality control measures is the inspection of the steel formwork before installation. This involves checking the formwork for any damages, defects, or deviations from the required specifications. Any issues found during the inspection should be addressed and resolved before proceeding with the installation. Another quality control measure is the verification of the dimensions and alignment of the steel formwork. This is done to ensure that the formwork is fabricated according to the required dimensions and that it is properly aligned with the structure. Inaccurate dimensions or misalignment can lead to problems during the concrete pouring process and can affect the quality of the final structure. Additionally, quality control measures include checking the stability and strength of the steel formwork. This involves verifying that the formwork is properly braced and supported to withstand the pressure exerted by the concrete. It is important to ensure that the formwork can handle the load without any deformation or failure. Furthermore, the installation process itself should be closely monitored to ensure compliance with the required procedures and standards. This includes checking that the formwork is securely fastened and that all connections are properly made. Any deviations from the installation procedures should be immediately addressed and corrected. Regular inspections and audits should be conducted throughout the installation process to track the progress and identify any potential issues. This allows for timely interventions and corrections, ensuring that the steel formwork installation meets the required quality standards. Overall, specific quality control measures for steel formwork installation are essential to ensure the integrity and safety of the structure. By implementing these measures, any potential issues or defects can be identified and resolved early on, minimizing the risk of costly rework or structural failures.

- Q: Can steel formwork be used for different types of concrete finishes?

- Yes, steel formwork can be used for different types of concrete finishes. Steel formwork is highly versatile and can be customized to create various concrete finishes such as smooth, textured, or patterned surfaces. The steel formwork allows for precise shaping and molding of the concrete, enabling the creation of different finishes according to the desired design and aesthetic requirements. Additionally, steel formwork can be easily adjusted and reused for different projects, making it a cost-effective choice for achieving diverse concrete finishes.

- Q: Can steel formwork be used for both reinforced and non-reinforced concrete structures?

- Yes, steel formwork can be used for both reinforced and non-reinforced concrete structures. Steel formwork provides a strong and durable framework for concrete pouring and can be easily customized to accommodate different structural requirements, whether it involves reinforcing steel bars or not.

- Q: Can steel formwork be used for both monolithic and composite construction?

- Yes, steel formwork can be used for both monolithic and composite construction.

- Q: Are there any specific safety measures to be followed during steel formwork installation?

- During steel formwork installation, it is important to adhere to specific safety measures. Here are some of the most crucial ones: 1. Personal Protective Equipment (PPE) must be worn by all workers involved. This includes safety helmets, gloves, safety glasses, and steel-toed boots. These protective gears are essential for safeguarding against potential head, hand, eye, and foot injuries. 2. Workers should undergo proper training and be competent in steel formwork installation. They should have a thorough understanding of the equipment used, correct installation techniques, and potential hazards associated with the work. 3. Before commencing the installation process, a thorough inspection of all formwork equipment, such as steel frames, braces, and connectors, should be conducted to identify any damage or defects. Damaged or defective equipment should be immediately replaced. 4. To ensure safety, a secure and stable platform should be established for workers to carry out the installation. This may involve the use of scaffolding or other supporting structures. The platform should be erected properly and undergo stability inspection prior to work commencement. 5. Fall protection measures should be implemented to prevent workers from falling during the installation process. This may include the use of guardrails, safety harnesses, and safety nets. Workers should receive adequate training on the proper use of fall protection equipment and procedures. 6. When moving and positioning steel formwork, proper lifting and handling techniques should be employed. Workers should avoid overexertion and utilize mechanical aids, such as cranes or hoists, when necessary. Additionally, workers should be mindful of their posture and avoid awkward or strenuous lifting positions. 7. Effective communication and coordination among workers are vital during steel formwork installation. Clear instructions, proper signaling, and a designated person in charge of coordinating the work are essential to prevent accidents and ensure a smooth and safe installation process. By adhering to these safety measures, the risk of accidents and injuries during steel formwork installation can be significantly reduced, thereby creating a safer working environment for all individuals involved.

- Q: Can steel formwork be used for both standard and non-standard concrete sections?

- Steel formwork is suitable for both standard and non-standard concrete sections. It is a highly versatile option that can be customized to fit different shapes and sizes of concrete sections. Construction projects that involve unique or complex concrete structures often utilize steel formwork. It offers flexibility in creating non-standard shapes like curves, slopes, and irregular geometries. Moreover, steel formwork provides excellent strength and durability, making it perfect for both standard and non-standard concrete sections that require high load-bearing capacity. Its reusability also contributes to its cost-effectiveness, making it a viable choice for projects with varying concrete sections. In summary, steel formwork is the ideal solution for construction projects that require the flexibility and strength to accommodate both standard and non-standard concrete sections.

- Q: How does steel formwork handle formwork stability during concrete pouring?

- Steel formwork provides excellent formwork stability during concrete pouring due to its high strength and rigidity. It can withstand the pressure and weight of the fresh concrete without deformation or collapse, ensuring the desired shape and structure of the concrete elements. Additionally, steel formwork can be easily adjusted and secured in place, allowing for precise alignment and stability during the pouring process.

- Q: What are the common safety certifications for steel formwork systems?

- The common safety certifications for steel formwork systems include ISO 9001:2015, OHSAS 18001, and EN 12811-1.

- Q: Can steel formwork be used for complex geometric designs?

- Yes, steel formwork can be used for complex geometric designs. Steel is a versatile material that can be easily shaped and molded into various intricate forms, making it suitable for complex geometric designs. Steel formwork allows for precise and accurate construction, ensuring that the desired shape and dimensions of the design are achieved. Additionally, the strength and durability of steel make it suitable for supporting the weight and pressure exerted during the concrete pouring process. This makes steel formwork a reliable choice for creating complex geometric designs in construction projects.

Send your message to us

Steel Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords