Steel frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

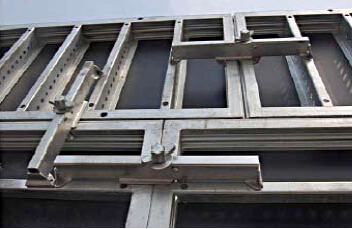

System Details & Application:

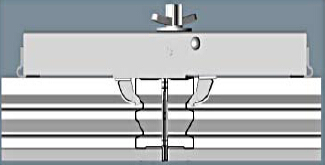

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for elevated walkways?

- Yes, steel formwork can be used for elevated walkways. Steel formwork is a versatile and durable construction material that can be used for various applications, including the construction of elevated walkways. Steel formwork systems are known for their strength and stability, making them ideal for supporting the weight and load of a walkway. The use of steel formwork for elevated walkways ensures a safe and robust structure that can withstand heavy foot traffic and adverse weather conditions. Additionally, steel formwork offers flexibility in design, allowing for the creation of customized walkways with different shapes and sizes. Overall, steel formwork is a suitable choice for constructing elevated walkways due to its strength, durability, and versatility.

- Q: What are the standard sizes of steel formwork panels?

- The standard sizes of steel formwork panels vary depending on the manufacturer and project requirements. However, commonly used sizes include 1.2 meters by 2.4 meters (4 feet by 8 feet), 1.5 meters by 3 meters (5 feet by 10 feet), and 2.4 meters by 3.6 meters (8 feet by 12 feet).

- Q: How does steel formwork contribute to the overall efficiency of concrete placement?

- Steel formwork plays a crucial role in enhancing the overall efficiency of concrete placement. Firstly, steel formwork is highly durable and can withstand the pressure exerted by fresh concrete. This durability ensures that the formwork remains intact during the pouring and curing process, thereby minimizing the need for repairs or replacements. Consequently, the construction process can proceed smoothly without delays, resulting in improved efficiency. Additionally, steel formwork is known for its high strength and stability. This allows for the construction of larger and taller concrete structures, as the formwork can support the weight and pressure of the concrete without buckling or deforming. With steel formwork, contractors have the flexibility to construct complex shapes and designs, enabling them to meet specific architectural requirements efficiently. Moreover, steel formwork offers easy and precise assembly. Its modular nature allows for quick installation and dismantling, reducing construction time significantly. The standardized components ensure that the formwork is accurately aligned, leading to consistent and uniform concrete placement. This not only enhances the efficiency of the construction process but also contributes to the quality and aesthetics of the final concrete structure. Furthermore, steel formwork is reusable. Unlike traditional timber formwork, steel formwork can be utilized multiple times, reducing material waste and saving costs. The ability to reuse the formwork eliminates the need for constant procurement and disposal of materials, streamlining the construction process and improving overall efficiency. Lastly, steel formwork provides a smooth finish to the concrete surface. The rigid structure of steel formwork prevents any bulges or deformities, resulting in a flat and even concrete surface. This eliminates the need for additional surface treatments, such as plastering or grinding, saving time and resources. The smooth finish not only enhances the aesthetic appeal of the concrete structure but also improves its durability and longevity. In conclusion, steel formwork significantly contributes to the overall efficiency of concrete placement. Its durability, strength, easy assembly, reusability, and ability to provide a smooth finish make it an invaluable tool in the construction industry. By utilizing steel formwork, contractors can expedite the construction process, reduce material waste, and achieve high-quality concrete structures efficiently.

- Q: How does steel formwork handle concrete finishing and curing agents?

- Steel formwork, a material specifically designed for concrete finishing and curing, is highly durable and versatile. Its strength and rigidity ensure a stable structure for controlled pouring and curing of concrete. During the concrete finishing stage, steel formwork allows for the smooth and even application of various finishing agents like troweling, brushing, or spraying. The smooth surface of steel formwork facilitates easy application and manipulation of these agents, resulting in a uniform and aesthetically pleasing finish. Furthermore, steel formwork is resistant to chemical reactions with concrete curing agents. These curing agents, such as sealers, compounds, or coatings, enhance the strength, durability, and appearance of freshly poured concrete. Steel formwork's non-reactive nature allows for the application and absorption of these agents by the concrete without any negative impact on the formwork material. Moreover, steel formwork is non-absorbent, meaning it does not soak up moisture from curing agents or the concrete itself. This characteristic is vital during the curing process as it allows the concrete to maintain its moisture content, ensuring proper hydration and strength development. Additionally, the non-absorbent nature of steel formwork prevents potential damage or degradation that could arise from moisture absorption, expansion, or corrosion. In conclusion, steel formwork is an excellent choice for handling concrete finishing and curing agents due to its strength, rigidity, non-reactive nature, and non-absorbent properties. It provides a stable structure for applying finishing agents while supporting proper curing and moisture retention in the concrete.

- Q: How does steel formwork affect the overall flexibility of the construction process?

- Steel formwork can significantly enhance the overall flexibility of the construction process. Due to its robustness and durability, steel formwork allows for the creation of complex and intricate designs, making it suitable for various construction projects. It enables the construction team to easily modify and adapt the formwork to meet specific project requirements, resulting in a more flexible construction process. Additionally, steel formwork can be easily dismantled and reused, providing cost-saving benefits and reducing construction waste.

- Q: How does steel formwork handle concrete temperature differentials?

- Steel formwork is a popular choice for concrete construction due to its durability and strength. When it comes to handling concrete temperature differentials, steel formwork offers several advantages. Firstly, steel has a high coefficient of thermal conductivity, meaning it can quickly absorb and distribute heat. This property allows steel formwork to efficiently dissipate the heat generated during the hydration process of concrete. As a result, steel formwork helps to minimize the risk of thermal cracking caused by temperature differentials. Furthermore, steel formwork is known for its dimensional stability. Unlike other materials like wood, steel does not expand or contract significantly with temperature changes. This stability ensures that the formwork maintains its shape and integrity, even when exposed to varying concrete temperatures. It helps to prevent any distortions, warping, or bulging that could affect the quality and appearance of the concrete structure. Additionally, steel formwork is resistant to fire and high temperatures, making it suitable for handling concrete that undergoes rapid temperature changes, such as in hot weather conditions or during the curing process. Its ability to withstand extreme temperatures without deforming or losing its structural integrity ensures that the formwork remains intact and provides the necessary support and containment for the concrete. In summary, steel formwork effectively handles concrete temperature differentials by efficiently dissipating heat, maintaining dimensional stability, and withstanding high temperatures. These properties contribute to the overall quality and durability of the concrete structure, while minimizing the risk of thermal cracking and other issues caused by temperature variations.

- Q: How does steel formwork affect the overall aesthetics of a structure?

- Steel formwork does not have a direct impact on the overall aesthetics of a structure as it is a temporary structure used for shaping and supporting concrete during construction. However, steel formwork can indirectly affect aesthetics by allowing for precise and smooth finishes, resulting in a more visually appealing final product. Additionally, steel formwork's strength and durability ensure structural integrity, which is essential for maintaining the long-term aesthetics of the structure.

- Q: How does steel formwork compare to aluminum formwork in terms of cost?

- Compared to aluminum formwork, steel formwork generally tends to be more expensive in terms of cost. This is because steel is a stronger and more durable material, leading to higher production and material costs. Additionally, due to its heavier weight, steel formwork requires more labor for handling and installation. On the other hand, aluminum formwork is lighter and easier to handle, reducing labor costs and increasing construction efficiency. Furthermore, aluminum formwork can be reused multiple times, resulting in significant cost savings for multiple projects. In summary, steel formwork offers superior strength and durability but comes with a higher initial cost compared to aluminum formwork, considering material and labor factors.

- Q: What are the different types of edge protection systems used in steel formwork?

- There are several types of edge protection systems used in steel formwork, including steel guardrails, toeboards, mesh panels, and safety nets. These systems are designed to prevent workers from falling or objects from being dropped off the edges of the formwork, ensuring a safe working environment.

- Q: Can steel formwork be used for curved or irregularly shaped structures?

- Yes, steel formwork can be used for curved or irregularly shaped structures. Steel formwork is highly flexible and can be easily customized to match the desired shape or form of the structure. Its strength and durability make it suitable for various construction projects, including those that involve unique or unconventional designs.

Send your message to us

Steel frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords