Steel Frame SF140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

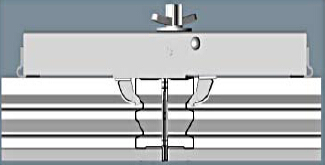

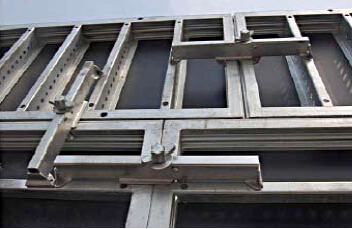

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork affect the overall project timeline?

- Steel formwork can have a positive impact on the overall project timeline. Its durability and reusability allow for faster and more efficient construction processes, reducing the time required for formwork installation and removal. Additionally, steel formwork often requires less maintenance and repairs compared to traditional wooden formwork, minimizing potential delays caused by formwork issues.

- Q: Can steel formwork be used for both thin and thick concrete elements?

- Yes, steel formwork can be used for both thin and thick concrete elements. Steel formwork is versatile and can be easily adjusted or modified to accommodate different thicknesses of concrete. It provides strength and stability, making it suitable for various construction projects, such as walls, columns, beams, slabs, and even complex architectural structures. Steel formwork also offers a smooth and precise finish to the concrete, ensuring high-quality results. Additionally, steel formwork is durable and can be reused multiple times, making it a cost-effective choice for both thin and thick concrete elements.

- Q: How does steel formwork contribute to the strength of the structure?

- Steel formwork contributes to the strength of a structure by providing a rigid framework that supports the concrete during the pouring and curing process. This ensures that the concrete is evenly distributed and properly shaped, resulting in a more durable and structurally sound building. The steel formwork also helps prevent any deformation or collapse of the structure under the weight and pressure of the concrete, ultimately enhancing its overall strength and stability.

- Q: Can steel formwork be used for decorative concrete finishes?

- Yes, steel formwork can be used for decorative concrete finishes. It provides sturdy support and precise shaping, allowing for intricate designs and smooth finishes in decorative concrete applications.

- Q: How is steel formwork secured to the ground?

- To ensure stability and safety during the construction process, there are several methods available for securing steel formwork to the ground. Ground anchors are commonly used, typically made of steel or concrete. These anchors are driven into the ground at regular intervals along the formwork's perimeter. Steel rods or cables are then used to connect the anchors with the formwork, creating a strong and secure attachment to the ground. Alternatively, steel stakes can be employed when the ground is unsuitable for ground anchors, such as in rocky or uneven terrains. These stakes are driven into the ground at regular intervals, and the formwork is attached to them using various clamps or brackets. In addition to ground anchors and stakes, concrete footing or foundation can also be utilized to secure the steel formwork to the ground. This method involves pouring concrete footings or foundations at regular intervals along the formwork's perimeter. Bolts or other fasteners are then employed to attach the formwork to the concrete, ensuring a solid and stable connection. The specific method for securing steel formwork to the ground may vary depending on the construction project's requirements and the ground conditions. Following the manufacturer's instructions and consulting with structural engineers is crucial to ensure the proper installation and secure attachment of the formwork to the ground.

- Q: Can steel formwork be customized for specific project requirements?

- Yes, steel formwork can be customized for specific project requirements. Steel is a highly versatile material that can be easily molded and shaped according to the specific needs of a project. This allows for the creation of various sizes, shapes, and designs to accommodate different construction requirements. Steel formwork can be easily modified or adjusted on-site to meet the specific dimensions and specifications of a project. Additionally, steel formwork can also be pre-fabricated off-site, where it can be tailored to the exact requirements of the project before being transported to the construction site. This customization of steel formwork ensures that it can be effectively used in a wide range of construction projects, including complex structures, high-rise buildings, bridges, tunnels, and more.

- Q: Can steel formwork be used for architectural construction projects?

- Indeed, architectural construction projects can utilize steel formwork. This versatile and durable construction material is commonly employed in architectural projects due to its numerous advantages. Steel formwork provides high strength, stability, and reusability. It can withstand high pressure and deliver a smooth and precise finish to concrete structures. Moreover, it is resistant to warping, bending, and shrinking, guaranteeing the structural integrity of the construction. Steel formwork is highly customizable, accommodating any shape or size, thus enabling architects to design unique and intricate structures. Thanks to its strength and durability, steel formwork can be reused multiple times, making it a cost-effective choice for construction projects. All in all, steel formwork is a dependable and efficient option for architectural construction endeavors.

- Q: What are the common challenges faced during steel formwork removal?

- One of the common challenges faced during steel formwork removal is the difficulty in disassembling the formwork due to the tight connections and fasteners used in its construction. Steel formwork is designed to provide a rigid structure, and as a result, it can be challenging to remove without the proper tools and techniques. Another challenge is the weight of the steel formwork. Steel is a heavy material, and when used in formwork, it can make the removal process physically demanding. Proper lifting equipment and techniques are required to safely remove the formwork without causing any injuries to the workers. Corrosion can also be a challenge during steel formwork removal. Over time, steel formwork can be exposed to moisture, which can lead to rust and corrosion. This can make the formwork more difficult to dismantle, as the rusted parts may be stuck together or weakened. Proper maintenance and regular inspections can help prevent or identify corrosion early on, reducing the challenges during removal. Additionally, the presence of concrete residue can pose challenges during steel formwork removal. Concrete can adhere to the formwork, making it difficult to separate the two. This can be time-consuming and may require additional tools or methods, such as chipping or using release agents, to facilitate the removal process. Lastly, the coordination and timing of the formwork removal can be a challenge. Removing the formwork too early can result in structural instability, while removing it too late can cause delays in subsequent construction activities. Proper planning and communication between the construction team are crucial to ensure the formwork removal is done at the right time and in the correct sequence. In conclusion, the common challenges faced during steel formwork removal include tight connections and fasteners, the weight of the formwork, corrosion, concrete residue, and coordination and timing. Overcoming these challenges requires proper tools, techniques, maintenance, and effective communication among the construction team.

- Q: Are there any specific design considerations for steel formwork systems?

- Yes, there are several specific design considerations for steel formwork systems. Firstly, the design of steel formwork systems should consider the load-bearing capacity of the structure. Steel formwork systems should be designed to withstand the weight of the concrete being poured, as well as any additional loads such as workers or construction equipment. The design should ensure that the steel formwork is strong enough to support these loads without any deformation or failure. Secondly, the design of steel formwork systems should take into account the dimensional accuracy and stability requirements of the concrete structure. Steel formwork systems need to be designed with precision and accuracy to ensure that the final concrete structure meets the desired specifications. The formwork should be rigid and stable, preventing any movement or shifting during the concrete pouring and curing process. Additionally, the design of steel formwork systems should consider the ease of assembly, disassembly, and reusability. Steel formwork systems are typically assembled and disassembled multiple times throughout a construction project. Therefore, the design should allow for easy and efficient installation and removal, minimizing downtime and labor costs. Furthermore, the steel formwork should be durable and reusable, reducing the need for frequent replacement and contributing to cost savings. Lastly, the design of steel formwork systems should consider safety aspects. The formwork should be designed to provide a safe working environment for construction workers. This includes features such as non-slip surfaces, guardrails, and safety barriers to prevent falls or accidents. The design should also incorporate proper access and egress points, ensuring easy movement for workers within the formwork system. In summary, specific design considerations for steel formwork systems include load-bearing capacity, dimensional accuracy, ease of assembly and reusability, and safety features. By taking these factors into account, designers can ensure the successful and efficient construction of concrete structures using steel formwork systems.

- Q: What are the common maintenance practices for steel formwork?

- To ensure the steel formwork's optimal performance, various maintenance practices should be followed. These include regular cleaning and inspection, lubrication of movable parts, repair of any damage or wear, and appropriate storage when not in use. To maintain cleanliness, it is crucial to remove any concrete residue, dirt, or debris that may accumulate on the formwork. This can be achieved by using water, a mild detergent, and a stiff brush. Caution should be exercised to avoid abrasive materials or chemicals that may harm the steel. It is necessary to conduct routine inspections to identify signs of wear, damage, or corrosion. This should be done both before and after each use of the formwork. Any cracks, deformations, or loose parts should be promptly repaired or replaced to ensure the formwork remains safe and functional. Lubricating moving parts, such as hinges, locks, and adjustable components, is of utmost importance to guarantee smooth operation. Applying a suitable lubricant to these parts helps prevent rust, corrosion, and sticking. This practice helps maintain the formwork's functionality and ease of use. Repairing any damage or wear is vital to uphold the structural integrity of the formwork. Swift action should be taken to repair any cracks or deformations using appropriate methods like welding or reinforcing. Damaged parts must be replaced with new ones to uphold the formwork's strength and stability. Proper storage is essential to prolong the lifespan of steel formwork and prevent damage. It should be stored in a dry and well-ventilated area to avoid corrosion. Additionally, formwork should be stacked or stored in a manner that prevents distortion or bending of the steel components. Furthermore, protecting the formwork from moisture and excessive heat is crucial to avoid potential damage. By adhering to these common maintenance practices, the steel formwork can be preserved in excellent condition, ensuring its durability and reliability for future use.

Send your message to us

Steel Frame SF140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords