Steel Frame SF140 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

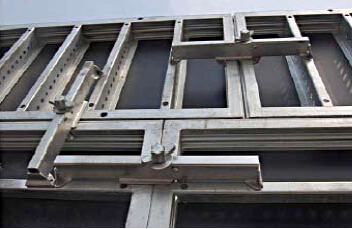

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

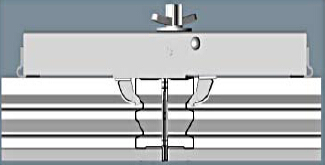

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for architectural concrete finishes?

- Architectural concrete finishes can indeed utilize steel formwork. Steel formwork possesses several advantages that render it suitable for producing top-notch architectural finishes. Firstly, it offers exceptional dimensional accuracy and stability, guaranteeing that the concrete is poured and cured in the desired size and shape. This enables the achievement of precise and intricate architectural detailing. Moreover, steel formwork is highly durable and capable of withstanding the pressure and weight imposed by the concrete during the pouring and curing stages. Its durability ensures that the formwork remains intact, preventing any deformation or warping and resulting in a smooth and uniform concrete finish. Additionally, steel formwork facilitates easy demolding as it can be effortlessly dismantled without causing any harm to the concrete structure. This convenience is particularly advantageous for achieving architectural finishes that necessitate complex shapes or multiple components. Furthermore, steel formwork can be readily reused, making it a cost-effective choice for architectural projects. Its ability to withstand multiple uses reduces the necessity for frequent replacements, saving both time and money. However, it is crucial to acknowledge that the selection of formwork material depends on the specific requirements of the architectural concrete finish. While steel formwork proves suitable for most applications, there may be instances where alternative materials such as wood or plastic formwork are more appropriate. Seeking advice from a structural engineer or construction professional can aid in determining the most suitable formwork material for a particular architectural concrete finish.

- Q: Are there any specific considerations for using steel formwork in earthquake-prone areas?

- In earthquake-prone areas, there are specific factors to consider when using steel formwork. Steel formwork is preferred in seismic regions due to its strength and durability. However, certain aspects need to be taken into account: 1. Flexibility is crucial. Steel formwork must be designed to withstand seismic forces and absorb and dissipate energy during an earthquake to minimize structural damage. 2. Connection details must be carefully engineered to ensure proper load transfer and resistance to seismic forces. Special attention should be given to joints and connections to prevent failure during an earthquake. 3. Additional reinforcement may be necessary to enhance the strength and stiffness of the steel formwork system. This can include extra steel bars, cross bracing, or diagonal struts to resist lateral forces. 4. Proper anchorage of the steel formwork is vital in earthquake-prone areas. It should be securely anchored to the foundation or structural elements to prevent displacement or movement during an earthquake. 5. Regular inspection and maintenance of the steel formwork system are essential in earthquake-prone areas. Any damage or wear should be promptly identified and repaired to maintain the system's integrity and stability. 6. Compliance with local building codes and regulations for seismic design is crucial. These codes provide guidelines and requirements for the design, installation, and use of formwork in earthquake-prone areas. By considering these specific factors, the use of steel formwork in earthquake-prone areas can enhance structural resilience and contribute to the overall safety and durability of construction projects.

- Q: What are some of the components of the combined steel template, what role?

- The steel template is provided with the template system which is composed of a variety of specifications of the standard steel template and the connecting piece and the supporting parts. The template system has strong versatility, flexible assembly, convenient assembly and disassembly, high strength, high rigidity, high precision, tight joints, smooth surface, rapid assembly and can be assembled into large, mechanized construction; turnover frequency (50 times), wood saving, reduce construction cost and other advantages. Only one-time investment is higher. It is a widely used template type and system in china. This technology is applicable to industrial and civil construction of cast-in-situ concrete frame and cast in place concrete columns, beams, plates, shear walls and other formwork works.

- Q: Can steel formwork be used in areas with high seismic activities?

- Yes, steel formwork can be used in areas with high seismic activities. Steel is a strong and durable material that can withstand the forces generated during an earthquake. It provides stability and structural integrity, making it suitable for use in seismic zones. Additionally, steel formwork can be easily assembled and disassembled, allowing for efficient construction practices in areas prone to earthquakes.

- Q: Can steel formwork be used for both manual and mechanical concrete pouring?

- Yes, steel formwork can be used for both manual and mechanical concrete pouring. Steel formwork is known for its durability and strength, making it suitable for handling the pressure and weight of concrete, whether it is poured manually or mechanically. It provides a stable and rigid structure that can withstand the forces exerted during pouring and curing of concrete. Additionally, steel formwork is versatile and can be easily adjusted or reassembled to accommodate different shapes and sizes of concrete structures. Hence, it is commonly used in construction projects where both manual and mechanical concrete pouring methods are employed.

- Q: How does steel formwork handle different concrete reinforcement types?

- Steel formwork is a versatile and durable option for handling different types of concrete reinforcement. It is commonly used in construction projects to create temporary molds or structures to hold concrete in place during the pouring and curing process. One of the advantages of steel formwork is its ability to handle different concrete reinforcement types. Whether it is traditional reinforcement such as steel bars or modern reinforcement techniques like fiber-reinforced polymers (FRP), steel formwork can accommodate them all. Steel formwork is designed to be strong and rigid, which allows it to support the weight and pressure exerted by different types of reinforcement materials. Whether it is the weight of steel bars or the tensile strength of FRP, steel formwork can withstand these forces without deforming or collapsing. Additionally, steel formwork is highly adaptable and can be easily adjusted or modified to accommodate different reinforcement types. It can be cut or welded to create openings or recesses for steel bars or other reinforcement materials to pass through. This flexibility ensures that steel formwork can be customized to suit the specific needs of each construction project. Furthermore, steel formwork offers a smooth and even surface finish, which is crucial for ensuring proper adhesion between the concrete and the reinforcement materials. This ensures that the reinforcement is securely embedded within the concrete structure, providing the necessary structural integrity and strength. In conclusion, steel formwork is a reliable and effective solution for handling different concrete reinforcement types. Its strength, adaptability, and ability to provide a smooth surface finish make it an ideal choice for construction projects that require diverse reinforcement materials.

- Q: What are the considerations when designing steel formwork for retaining walls?

- When designing steel formwork for retaining walls, several considerations need to be taken into account. First, the formwork should be strong enough to withstand the pressure exerted by the wet concrete, ensuring it does not collapse or deform during the pouring process. Additionally, the formwork should be able to resist the lateral pressure exerted by the soil behind the retaining wall. Proper bracing and reinforcement are crucial to ensure stability. The formwork should also be designed to allow for easy removal once the concrete has cured, considering factors such as the type of release agent used and the desired finish of the wall. Lastly, considerations should be given to factors such as cost, time, and ease of assembly and disassembly, as these can impact the overall efficiency and effectiveness of the formwork.

- Q: How does steel formwork affect the overall waste management of the construction process?

- The overall waste management of the construction process can be significantly impacted by steel formwork. Unlike traditional timber formwork, steel formwork is highly durable and can be reused multiple times, which helps to minimize the generation of waste. This is because steel formwork does not need frequent replacements, resulting in a reduction of waste from discarded formwork materials. Additionally, steel formwork is usually fabricated off-site and can be easily disassembled and transported to different construction sites. This not only saves time and labor but also decreases the amount of waste produced during the construction process. Apart from its reusability, steel formwork is also recyclable. When it reaches the end of its life cycle, steel formwork can be melted down and used to create new steel products. This creates a closed-loop recycling system that reduces the requirement for raw material extraction and minimizes the environmental impact associated with steel production. Another factor to consider is the reduced maintenance needed for steel formwork compared to other types of formwork. Due to its high resistance to wear and tear, steel formwork requires minimal repairs or replacements. This further reduces the waste generated during the construction process. Furthermore, steel formwork provides better dimensional accuracy and stability than other formwork materials. This results in reduced material wastage as the formwork ensures precise shape and alignment, minimizing the need for excessive concrete pouring or trimming. In conclusion, the use of steel formwork has a positive impact on waste management in the construction process by minimizing waste generation, promoting reusability, facilitating recycling, reducing maintenance needs, and improving construction accuracy.

- Q: Are there any fire safety considerations when using steel formwork?

- Yes, there are fire safety considerations when using steel formwork. Steel is a non-combustible material, which means it does not burn or contribute to the spread of fire. However, during a fire, steel can lose its strength and structural integrity due to high temperatures. This can lead to structural failure, collapse, and the potential for injuries or fatalities. To mitigate these risks, it is important to implement proper fire safety measures when using steel formwork. Some considerations include: 1. Fire-resistant coatings: Applying fire-resistant coatings to the steel formwork can help protect it from heat and reduce the risk of structural failure during a fire. These coatings can provide additional fire resistance and can be rated for specific fire durations. 2. Adequate fire protection systems: Installing and maintaining fire protection systems, such as sprinklers, fire extinguishers, and fire alarms, is important to detect and extinguish fires early on. This can help prevent the fire from reaching the steel formwork and minimize the risk of structural damage. 3. Fire-resistant barriers: Installing fire-resistant barriers, such as fire-rated walls or partitions, can help contain the spread of fire and provide additional protection to the steel formwork. These barriers can limit the exposure of the formwork to high temperatures and minimize the risk of structural failure. 4. Regular inspections and maintenance: Regularly inspecting the steel formwork for any signs of damage or corrosion is crucial for identifying potential weak points that could compromise its fire resistance. Any issues should be promptly addressed, and damaged or corroded sections should be repaired or replaced. 5. Adequate fire escape routes: Ensuring that there are accessible and well-marked fire escape routes in the vicinity of the steel formwork is essential to ensure the safety of workers in the event of a fire. These escape routes should be clear of any obstructions and easily accessible to allow for quick evacuation. By implementing these fire safety considerations, the risk of structural failure and injuries related to steel formwork can be significantly reduced. It is important to comply with local building codes and regulations and consult with fire safety professionals to ensure appropriate fire protection measures are in place.

- Q: How does steel formwork affect the overall construction site waste recycling?

- The overall waste recycling at a construction site can be greatly influenced by steel formwork. In contrast to traditional timber formwork, steel formwork is more long-lasting and can be reused multiple times. This results in a decrease in waste production at the construction site since there is less necessity for the production and disposal of new formwork materials. Furthermore, cleaning and maintaining steel formwork is simpler, which extends its lifespan and reduces the need for replacement. This not only decreases waste but also saves costs associated with purchasing new formwork materials for each construction project. Moreover, steel formwork is highly recyclable. Once its life cycle is complete, it can be recycled and utilized to manufacture new steel products, diminishing the demand for fresh materials and reducing the environmental impact. Through the utilization of steel formwork, construction sites can greatly diminish their waste generation and contribute to a more sustainable construction industry. This not only benefits the environment but also promotes a more efficient and cost-effective approach to construction.

Send your message to us

Steel Frame SF140 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords