Steel-Frame Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

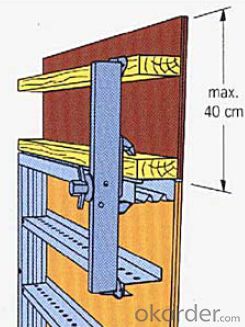

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork handle different concrete expansion properties?

- Steel formwork is a highly versatile and reliable choice when it comes to handling different concrete expansion properties. The primary reason for this is that steel has excellent tensile strength and durability, allowing it to withstand the forces exerted by expanding concrete. Concrete expands and contracts due to temperature changes, moisture absorption, and chemical reactions. Steel formwork is designed to accommodate these expansion properties through its flexible nature. The steel panels used in formwork systems can be easily adjusted, allowing for expansion and contraction without causing damage to the structure. In addition to its flexibility, steel formwork also provides stability to the concrete during the curing process. It prevents the concrete from sagging or deforming under its own weight, ensuring a uniform and even surface. This stability is crucial in preventing cracks or other structural issues caused by uneven expansion. Moreover, steel formwork is known for its heat conductivity. This property helps in dissipating heat generated during the hydration process of concrete, reducing the risk of thermal cracks. By efficiently managing the heat generated, steel formwork minimizes the impact of temperature fluctuations on the concrete's expansion properties. Furthermore, steel formwork can be easily reinforced with additional supports or braces, if needed, to further enhance its ability to handle different concrete expansion properties. These reinforcements can be strategically placed to provide additional strength and stability, allowing the formwork to accommodate any expansion or contraction without compromising the integrity of the structure. Overall, steel formwork is a reliable and effective choice for handling different concrete expansion properties. Its flexibility, stability, and ability to dissipate heat make it an ideal material for accommodating the natural movements of concrete, ensuring a durable and long-lasting structure.

- Q: Can steel formwork be used in areas with high wind uplift forces?

- Indeed, areas with high wind uplift forces can accommodate the use of steel formwork. Renowned for its robustness and longevity, steel formwork is an ideal choice for construction ventures in regions prone to high wind uplift forces. By incorporating supplementary reinforcement and bracing, the steel formwork system can be tailored to endure these forces, ensuring steadfastness and averting potential harm or malfunction. Engineering calculations and structural analysis can be undertaken to ascertain the specific criteria essential for the steel formwork to withstand the formidable high wind uplift forces. Moreover, the implementation of appropriate installation and anchoring techniques can further fortify the steel formwork system against these forces.

- Q: Can steel formwork be used for both straight and sloping structures?

- Yes, steel formwork can be used for both straight and sloping structures. Steel formwork is a versatile and flexible construction material that can be customized to fit various shapes and configurations. It can be easily adjusted and secured to create straight walls and columns. Additionally, with the use of specialized accessories and components, steel formwork can also be adapted to create sloping structures such as ramps, inclined walls, and curved surfaces. This flexibility and adaptability make steel formwork a preferred choice for construction projects with varying design requirements.

- Q: Can steel formwork be used for theater construction projects?

- Yes, steel formwork can be used for theater construction projects. Steel formwork refers to temporary or permanent molds made of steel that are used to shape and support concrete during the construction process. It is a versatile and durable formwork material that can be used for various construction projects, including theater construction. Steel formwork offers several advantages for theater construction projects. First, it provides a high level of strength and stability, ensuring that the concrete structures built for theaters are sturdy and long-lasting. This is particularly important in theaters, where safety is a top priority due to the large number of people that gather in these spaces. Additionally, steel formwork allows for intricate and complex designs to be achieved, which is often required in theater construction. The flexibility of steel formwork enables the creation of customized shapes, curves, and patterns, allowing architects and designers to bring their creative vision to life. Moreover, steel formwork is reusable, which makes it a cost-effective option for theater construction projects. Unlike traditional wooden formwork that needs to be replaced after a single use, steel formwork can be used multiple times, reducing material and labor costs. Lastly, steel formwork offers a faster construction process. Its ease of assembly and disassembly speeds up the construction timeline, allowing theater projects to be completed in a shorter time frame. In conclusion, steel formwork is a suitable choice for theater construction projects due to its strength, versatility, flexibility, reusability, and efficiency. It offers numerous benefits that contribute to the successful and timely completion of theater construction projects.

- Q: What are the common safety guidelines when working with steel formwork in confined spaces?

- When working with steel formwork in confined spaces, some common safety guidelines include ensuring proper ventilation to prevent the buildup of hazardous gases, regularly monitoring the atmosphere for toxic substances, providing adequate lighting and emergency exit routes, wearing appropriate personal protective equipment such as gloves, safety glasses, and respiratory protection, training workers on the potential hazards and safe work practices, and having a standby person outside the confined space to monitor and assist if needed.

- Q: Are there any special considerations when using steel formwork in cold weather conditions?

- Special considerations should be taken into account when using steel formwork in cold weather conditions. Firstly, the cold temperatures can cause steel to contract and become more brittle, increasing the risk of cracks or fractures in the formwork. Therefore, it is important to ensure that the steel formwork is properly designed and reinforced to withstand the potential stress caused by temperature changes. Secondly, the curing process of concrete can be affected by the cold weather. Steel formwork tends to conduct heat away from the concrete, slowing down the curing process. This can result in insufficient strength development and compromise the structural integrity. To address this, additional measures may be necessary, such as using insulating materials or applying external heat sources to maintain optimal curing conditions. Furthermore, cold weather can lead to the formation of ice on the surface of the steel formwork due to moisture freezing. This can increase the weight of the formwork and make its removal difficult. Additionally, it can cause damage if not properly managed. Therefore, preventive measures must be taken, such as using anti-freeze agents or ensuring adequate drainage to prevent ice buildup. Lastly, working in cold weather conditions can pose challenges for construction workers. It is crucial to implement appropriate safety measures, including providing sufficient insulation, heating facilities, and protective clothing to prevent workers from experiencing hypothermia or other cold-related illnesses. In conclusion, when working with steel formwork in cold weather conditions, it is important to consider the increased risk of brittleness, the impact on concrete curing, the potential for ice formation, and the well-being of workers. By taking these special considerations into account, the use of steel formwork can still be efficient and effective in cold weather conditions.

- Q: What are the different types of formwork accessories used with steel formwork?

- Steel formwork commonly utilizes various types of formwork accessories to enhance functionality, efficiency, and worker safety during construction. 1. Formwork clamps securely fasten formwork panels together, ensuring their stability and preventing movement during concrete pouring. They come in different sizes and designs to accommodate various formwork systems. 2. Formwork props are adjustable steel supports used to provide vertical stability and load-bearing capacity to formwork panels. This ensures worker safety while operating on the system. 3. Formwork ties firmly hold formwork panels in place, preventing bulging or deflection under the weight of concrete. Made of steel, they are available in different lengths and designs to meet project requirements. 4. Formwork connectors join formwork panels at corners or joints, ensuring a tight and secure fit. They come in various shapes and sizes, including corner connectors, wedge connectors, and pin connectors. 5. Formwork brackets support formwork panels horizontally, providing additional stability and reinforcement. They are commonly used in beam and slab construction to support formwork across long spans. 6. Formwork release agents are chemical substances applied to the formwork surface to prevent concrete adhesion. This allows for easy removal of the formwork after concrete curing, facilitating efficient and smooth formwork removal. In conclusion, these formwork accessories are vital for the success of a steel formwork system, providing the necessary support, stability, and reinforcement for efficient and safe construction of concrete structures.

- Q: How does steel formwork affect the overall stability of a structure?

- Steel formwork can greatly enhance the overall stability of a structure. Its rigid and durable nature provides strong support during the construction process, allowing for accurate placement and alignment of concrete. This ensures that the structure achieves the desired strength and integrity. Additionally, steel formwork offers excellent load-bearing capacity, minimizing the risk of deformation or collapse during and after construction. Its ability to withstand extreme weather conditions and resist external forces further contributes to the long-term stability and safety of the structure.

- Q: Can steel formwork be used for precast concrete columns?

- Yes, steel formwork can be used for precast concrete columns. Steel formwork offers durability and strength, making it suitable for creating precise and complex shapes required for precast concrete columns. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for precast concrete column production.

- Q: What are the different types of steel formwork joint solutions?

- Construction projects utilize various types of steel formwork joint solutions to enhance stability, strength, and flexibility in the formwork system. Commonly employed joint solutions include: 1. Butt Joint: This uncomplicated joint involves aligning and securing two steel formwork panels using bolts or clamps. It is easily assembled and disassembled, rendering it suitable for diverse construction applications. 2. Corner Joint: Used when two steel formwork panels meet at a corner, these joints entail overlapping the panels and securing them with bolts or clamps. Corner joints reinforce the formwork system, particularly in areas where walls or columns are being constructed. 3. T-Joint: When three steel formwork panels converge at a single point, T-joints are employed. These joints are created by overlapping the panels and securing them with bolts or clamps. T-joints are commonly utilized in projects involving complex shapes or structures. 4. L-Joint: Similar to T-joints, L-joints involve two steel formwork panels meeting at right angles. These joints are formed by overlapping the panels and securing them with bolts or clamps. L-joints are utilized for forming corners in formwork systems, such as during column or beam construction. 5. Hinged Joint: Hinged joints allow flexibility in the formwork system, enabling the panels to pivot or rotate to accommodate changes in shape or position. They are typically employed in curved or irregular structures where rigid joints may not be suitable. 6. Adjustable Joint: Adjustable joints facilitate height or width adjustments in the formwork system. These joints enable easy modification of formwork dimensions to accommodate changes in design or construction requirements. Adjustable joints are particularly useful in projects with varying dimensions or levels. It is crucial to select the appropriate steel formwork joint solution based on specific construction requirements and structural design. Proper installation and reinforcement of these joints ensure the stability and integrity of the formwork system, which is imperative for successful project execution.

Send your message to us

Steel-Frame Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords