Steel-frame formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

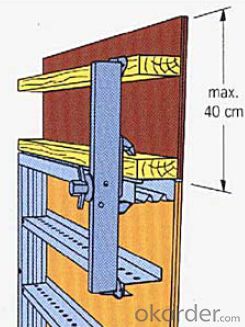

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used in heritage or conservation projects?

- Yes, steel formwork can be used in heritage or conservation projects. Steel formwork offers several advantages that make it suitable for such projects. Firstly, steel formwork is highly durable and long-lasting, which is crucial when working on historic structures that require preservation for future generations. It can withstand the rigors of construction and can be reused multiple times, making it a cost-effective solution. Additionally, steel formwork provides excellent strength and stability, ensuring accurate and precise concrete placement. This is especially important in heritage projects where maintaining the original design and structural integrity is crucial. The versatility of steel formwork also allows for complex shapes and intricate detailing, making it suitable for replicating historic architectural features. Furthermore, steel formwork is highly resistant to warping, shrinking, or expanding due to temperature changes and moisture, which can be common in conservation projects. This resistance ensures that the formwork remains stable throughout the construction process, minimizes the risk of damage to the heritage structure, and helps maintain the overall structural integrity. However, it is important to consider the specific requirements and restrictions of each heritage or conservation project. Some projects may have strict guidelines that require the use of traditional materials, in which case steel formwork may not be suitable. It is essential to consult with heritage experts and conservation specialists to ensure that the use of steel formwork aligns with the project's objectives and meets all necessary preservation standards.

- Q: How does steel formwork handle concrete bleeding and segregation?

- Steel formwork has a reputation for effectively managing concrete bleeding and segregation. Bleeding occurs when water in the concrete mixture rises to the surface, leaving a layer of water on top. Segregation, on the other hand, happens when the solid particles in the concrete mixture separate from the water, causing an uneven distribution. To minimize bleeding and segregation, steel formwork provides a sturdy structure that holds the concrete in place during pouring and curing. The strong construction and tight joints of steel formwork prevent any leaks or seepage, resulting in reduced bleeding. Moreover, steel formwork allows for better control over the placement and compaction of the concrete. The smooth and non-absorbent surface of steel formwork facilitates a uniform distribution of the concrete mixture, minimizing the risk of segregation. Additionally, using steel formwork enables proper vibration and consolidation of the concrete, eliminating any voids or air pockets that could contribute to segregation. Furthermore, steel formwork ensures stability during the curing process, preventing significant movement of the concrete. This stability helps avoid disturbances that could lead to bleeding or segregation. In conclusion, steel formwork is highly effective in managing concrete bleeding and segregation due to its rigid structure, tight joints, smooth surface, and stability. Its use promotes a more consistent and consolidated placement of concrete, resulting in a higher quality finished product.

- Q: Can steel formwork be used for soundproofing walls?

- No, steel formwork alone cannot be used for soundproofing walls. Soundproofing typically requires the use of specialized materials and techniques, such as acoustic insulation and sound-absorbing panels, to effectively reduce noise transmission.

- Q: How does steel formwork handle different weather conditions?

- Steel formwork is known for its durability and resistance to various weather conditions. It has the ability to handle extreme temperatures, heavy rain, strong winds, and even snow. One of the main advantages of steel formwork is its ability to withstand high temperatures. It does not deform or lose its structural integrity when exposed to extreme heat. This makes it suitable for use in hot climates where temperatures can reach high levels. In addition, steel formwork does not absorb heat easily, which means it remains cool to the touch even in direct sunlight. Steel formwork is also highly resistant to heavy rain and water exposure. It does not rot, warp, or degrade when in contact with water, making it ideal for use in areas with high rainfall or high humidity. Additionally, steel does not absorb moisture, preventing the growth of mold or mildew, which can be a concern with other types of formwork materials. Another advantage of steel formwork is its ability to withstand strong winds. The inherent strength and rigidity of steel make it highly resistant to wind loads. This is particularly important in areas prone to hurricanes, cyclones, or strong gusts of wind. Steel formwork provides stability and ensures that the structure remains intact even during severe weather conditions. Furthermore, steel formwork is capable of handling snow and cold temperatures. It does not crack or become brittle when exposed to freezing temperatures, making it suitable for use in cold climates. The strength and durability of steel formwork ensure that it can handle the weight of accumulated snow without any structural damage. In summary, steel formwork is a reliable and robust solution that can handle different weather conditions effectively. Its ability to withstand extreme temperatures, heavy rain, strong winds, and snow make it a popular choice in construction projects worldwide.

- Q: How does steel formwork affect the overall accuracy of concrete structures?

- The accuracy of concrete structures can be significantly improved through the use of steel formwork. By providing precise alignment and dimensional accuracy, steel formwork ensures a more uniform and accurate structure. To maintain the desired shape and dimensions of the concrete during pouring and curing, steel formwork offers a rigid and stable framework. This stability prevents any potential deformation or distortion, ensuring that the final structure adheres to its design specifications. Additionally, steel formwork contributes to a smoother surface finish of the concrete. The smoothness of the formwork surface reduces the likelihood of imperfections or irregularities in the final structure, ultimately enhancing its aesthetics and overall quality. Moreover, steel formwork allows for greater control and precision in the placement and positioning of reinforcement bars, which are crucial for the structural integrity of the concrete. Accurate placement of reinforcement bars guarantees proper embedding within the concrete, resulting in a stronger and more durable structure. Furthermore, the high level of reusability provided by steel formwork further enhances accuracy. Its durability allows for multiple uses, minimizing the risk of wear and tear that could affect the formwork's alignment and accuracy. In conclusion, steel formwork plays a vital role in ensuring the overall accuracy of concrete structures. It provides stability, precise alignment, smooth formwork surfaces, and reusability, all of which contribute to a more accurate and aesthetically pleasing final product.

- Q: What are the common design considerations for steel formwork in high-rise buildings?

- When it comes to designing steel formwork for high-rise buildings, there are several common considerations that need to be taken into account. These considerations are crucial for ensuring the structural integrity, safety, and efficiency of the formwork system. 1. Load capacity: Steel formwork needs to be able to withstand the loads it will be subjected to during the construction process. This includes the weight of the concrete, workers, equipment, and any other imposed loads. The formwork should be designed to have sufficient load capacity to prevent any deformation or failure. 2. Stability: High-rise buildings are subjected to various external forces such as wind and seismic loads. The formwork system needs to be stable and resistant to these forces to prevent any accidents or collapse. Proper bracing, tie-downs, and anchorage systems should be incorporated into the design to ensure stability. 3. Durability: Steel formwork must be able to withstand the harsh conditions of construction sites, including exposure to moisture, chemicals, and physical impact. The material selection and protective coatings should be chosen carefully to ensure long-term durability and prevent corrosion. 4. Flexibility: High-rise buildings often have complex geometries with different floor layouts, wall configurations, and column sizes. The formwork system should be flexible enough to accommodate these variations and allow for easy adjustments and reusability. Modular formwork systems are commonly used to provide this flexibility. 5. Safety: Safety is of utmost importance in high-rise construction. The design of the formwork system should incorporate safety features such as non-slip surfaces, guardrails, access platforms, and fall protection systems. Adequate space for workers to move around and perform their tasks safely should also be considered. 6. Construction timeline: Time is a critical factor in high-rise construction projects. The formwork system should be designed to enable fast and efficient construction, minimizing downtime and delays. This could involve using pre-fabricated components, easy assembly and disassembly methods, and efficient material handling systems. 7. Cost-effectiveness: The design of the steel formwork system should optimize cost-effectiveness without compromising on quality and safety. This includes factors such as material selection, formwork reuse, efficient use of labor, and minimizing waste. Overall, the design considerations for steel formwork in high-rise buildings revolve around load capacity, stability, durability, flexibility, safety, construction timeline, and cost-effectiveness. By carefully addressing these considerations, designers can ensure a successful and efficient construction process for high-rise buildings.

- Q: Can steel formwork be used in areas with limited labor availability?

- Yes, steel formwork can be used in areas with limited labor availability. Steel formwork is a versatile and durable system that requires less labor compared to traditional formwork methods. It is easy to assemble and disassemble, and can be reused multiple times, reducing the need for continuous labor for formwork construction. Additionally, steel formwork is lightweight and can be easily transported to remote areas, making it suitable for construction projects in locations with limited labor resources. Overall, the use of steel formwork can help streamline the construction process and optimize labor usage in areas with limited labor availability.

- Q: What are the common safety training requirements for steel formwork installation?

- To ensure worker safety and project success, steel formwork installation requires adherence to various safety training requirements. These requirements may differ based on local regulations and company policies. However, some common safety training requirements for steel formwork installation are as follows: 1. Comprehensive Construction Safety Training: Workers involved in steel formwork installation must undergo general construction safety training. This training covers topics like hazard identification, proper use of personal protective equipment (PPE), emergency procedures, and safe work practices. It equips workers with a basic understanding of construction site safety. 2. Fall Protection Training: Given the elevated nature of steel formwork installation, fall protection training is crucial. Workers must be trained on the appropriate use and inspection of fall protection equipment, such as harnesses, lanyards, and anchor points. They should also learn how to set up and dismantle temporary fall protection systems like guardrails and safety nets. 3. Training for Material Handling and Lifting: Steel formwork components can be heavy and require proper lifting techniques to prevent injuries. Workers should receive training on safe lifting practices, including correct body mechanics, proper use of lifting equipment like cranes or forklifts, and an understanding of load capacities. 4. Scaffold Safety Training: Scaffold usage is common in steel formwork installation to access higher areas. Workers should be trained on safe scaffold erection, inspection, and usage. This includes knowledge of scaffold components, stability, fall protection while on scaffolds, and safe work practices. 5. Electrical Safety Training: Steel formwork installation may involve working near electrical systems or equipment. Workers should receive training on electrical safety, including identifying electrical hazards, implementing lockout/tagout procedures, and maintaining safe distances from power lines. 6. Hazard Communication Training: Workers should undergo training on hazard communication protocols, including the identification and comprehension of safety data sheets (SDS) and proper handling of hazardous materials commonly used in steel formwork installation. 7. First Aid and CPR Training: In the event of an accident or injury on the job site, workers should be trained in basic first aid and cardiopulmonary resuscitation (CPR) techniques. This training enables workers to stabilize injured individuals until professional medical assistance arrives. Employers must ensure that all workers receive comprehensive safety training prior to beginning steel formwork installation. Regular refresher courses and ongoing safety awareness programs should also be conducted to reinforce safe work practices and maintain a high level of job site safety.

- Q: Can steel formwork be used in airport or transportation infrastructure projects?

- Yes, steel formwork can be used in airport or transportation infrastructure projects. Steel formwork is a versatile and durable option for construction projects, including those in the airport and transportation sectors. It offers several benefits such as high load-bearing capacity, ease of assembly and disassembly, and the ability to withstand harsh weather conditions and heavy usage. Steel formwork also provides excellent dimensional accuracy, ensuring precise and consistent results. Additionally, it can be easily reused, making it a cost-effective choice for large-scale projects like airports and transportation infrastructure. Overall, steel formwork is a suitable and efficient solution for constructing various elements in airport or transportation projects, such as foundations, columns, beams, and slabs.

- Q: How does steel formwork handle different concrete testing procedures?

- The construction industry favors steel formwork because of its durability and versatility. When it comes to concrete testing, steel formwork proves highly capable and efficient. To begin with, steel formwork can withstand the pressure and weight exerted by concrete during various testing procedures. Regardless of whether it's a compression test, slump test, or any other form of concrete testing, the robustness of steel formwork guarantees it remains intact and does not deform under the load. In addition, steel formwork provides a smooth and even surface for concrete testing. This is crucial for obtaining accurate test results since any irregularities or inconsistencies in the formwork can impact the quality and integrity of the concrete sample being tested. Steel formwork is renowned for its precision, ensuring the concrete is poured and shaped precisely as required for each specific testing procedure. Furthermore, steel formwork is adaptable and easily modified to accommodate different concrete testing procedures. It can be adjusted or reconfigured to meet the specific requirements of various tests, such as creating different shapes, sizes, or depths for concrete samples. This flexibility allows for efficient and accurate testing, as the formwork can be customized according to the testing procedure being carried out. Moreover, steel formwork is reusable, providing cost-effectiveness and sustainability in concrete testing. Unlike other types of formwork that may need to be discarded after a single use, steel formwork can be dismantled, cleaned, and reused multiple times. This reduces overall expenses associated with concrete testing procedures and minimizes waste generation, making it an environmentally friendly option. In conclusion, steel formwork is well-suited for handling different concrete testing procedures due to its strength, precision, adaptability, and reusability. It offers a stable and consistent surface for accurate testing, ensuring reliable results. With its numerous advantages, steel formwork remains the preferred choice in the construction industry for various concrete testing requirements.

Send your message to us

Steel-frame formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords