Steel-Frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

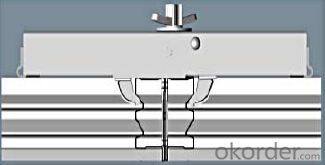

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the different types of ties used in steel formwork construction?

- Steel formwork construction utilizes various types of ties to hold the formwork panels together and ensure the stability and integrity of the structure. Some commonly used ties in this construction method include: 1. Snap ties are the most frequently employed ties in steel formwork construction. They consist of a metal rod and a flat plate. The rod is inserted through holes in the formwork panels, and the plate is attached to secure the panels. Snap ties are quick and easy to install and can be easily removed after the concrete cures. 2. Tie rods are long steel rods with threading on both ends. They are used to connect the formwork panels by passing them through the panel holes and securing them with nuts and washers. Tie rods provide robust and stable connections that can withstand high pressure and loads. 3. She-bolts are similar to tie rods but have a fixed female thread at one end. Used in combination with wing nuts and washers, she-bolts hold the formwork panels together. They are particularly useful when tie rods need to be quickly and easily removed. 4. Flat ties are flat-shaped steel wires or bars. They are inserted through the formwork panel holes and secured with cones or washers. Flat ties establish a secure connection between the panels and are commonly used in large-scale construction projects. 5. Coil ties are flexible steel wires coiled at one end and threaded at the other. They are inserted through the formwork panel holes and secured with cones or washers. Coil ties are especially advantageous in curved or irregular-shaped structures. 6. Combination ties merge the characteristics of snap ties and tie rods. They consist of a metal rod with a flat plate at one end and a threaded end at the other. Combination ties are versatile and can be utilized in diverse formwork applications. Choosing the appropriate tie type is crucial for steel formwork construction projects. Factors such as the structure's size and shape, required load-bearing capacity, and ease of installation and removal influence the tie selection.

- Q: Can steel formwork be used for airport construction projects?

- Yes, steel formwork can be used for airport construction projects. Steel formwork is a versatile and durable option for constructing various concrete structures, including those found in airports. It offers several advantages such as high strength, stability, and reusability, making it suitable for large-scale projects like airport construction. Steel formwork can withstand the heavy loads and pressures associated with airport infrastructure, allowing for the construction of runways, taxiways, aprons, and other structures. Additionally, its modular design and flexibility enable easy customization and adaptation to different project requirements. Overall, steel formwork is a reliable choice for airport construction projects due to its strength, durability, and adaptability.

- Q: How are steel formwork panels connected together?

- Steel formwork panels are usually connected together using a combination of different methods such as interlocking pins, bolts, or clamps. These connections ensure that the panels remain securely in place, forming a strong and stable structure for concrete pouring.

- Q: Can steel formwork be used for fire-resistant concrete structures?

- Yes, steel formwork can be used for fire-resistant concrete structures. Steel is known for its high strength and resistance to heat, making it an ideal material for constructing formwork for fire-resistant concrete structures. Additionally, steel formwork offers several advantages such as durability, reusability, and easy assembly and disassembly. It provides the necessary support and containment for pouring and curing fire-resistant concrete, ensuring the structure's integrity and safety in the event of a fire. However, it is important to note that the fire resistance of the concrete itself is determined by factors such as the mix design, aggregate selection, and thickness, and not solely dependent on the formwork material.

- Q: How does steel formwork impact the overall construction cost?

- Steel formwork can have a significant impact on the overall construction cost. While it may have a higher initial cost compared to other formwork materials, steel formwork offers durability, reusability, and strength, leading to reduced labor and material expenses. Its ability to withstand multiple uses and require less maintenance can offset the initial investment, making it a cost-effective choice in the long run. Additionally, steel formwork allows for faster construction cycles, leading to savings in labor costs and overall project timelines.

- Q: How is steel formwork used in construction projects?

- Steel formwork is a widely used construction technique that involves the use of steel panels and frames to create temporary molds or formworks. These formworks are used to shape and support wet concrete until it sets and hardens into the desired structure. In construction projects, steel formwork is primarily used for large-scale projects such as high-rise buildings, bridges, and dams. The use of steel formwork offers several advantages over traditional timber formwork, including increased strength, durability, and reusability. To use steel formwork, the first step is to design and fabricate the steel panels and frames according to the specific project requirements. These panels are typically made of high-quality steel, which makes them strong enough to withstand the weight and pressure of wet concrete. Once the steel formwork is fabricated, it is transported to the construction site and assembled by skilled workers. The panels are joined together using various connecting methods such as clamps or bolts to create a sturdy framework. This framework acts as a mold, providing support and containment for the wet concrete. The steel formwork is then carefully positioned and aligned in accordance with the project plans. Reinforcement bars, also known as rebars, are often placed within the formwork to add strength to the final structure. Once everything is in place, the concrete is poured into the formwork, filling up the designated areas. During the curing process, the steel formwork plays a crucial role in ensuring the concrete retains its shape and strength. The steel panels prevent the concrete from bulging or deforming under its own weight, resulting in a high-quality and structurally sound finished product. Once the concrete has hardened and gained enough strength, the steel formwork can be removed. Due to its durability and reusability, the steel formwork can be disassembled and used in multiple construction projects, making it a cost-effective and sustainable option. In conclusion, steel formwork is an essential component in construction projects as it provides a reliable and efficient method for shaping and supporting wet concrete. Its strength, durability, and reusability make it a popular choice for large-scale projects, ensuring the successful completion of various structures.

- Q: What are the common cost implications of using steel formwork in a construction project?

- The common cost implications of using steel formwork in a construction project include higher initial costs compared to other formwork materials, such as wood or plastic. However, steel formwork offers durability and can be reused multiple times, reducing the overall cost of formwork over the long term. Additionally, steel formwork provides better quality and accuracy in concrete finishing, saving costs on rework or repairs.

- Q: Production of steel plate for bridge steel plate SPHC and Q235 which material is good? What is the difference?

- SPHC this brand is actually the first brand in Germany, Japan also used,

- Q: I would like to ask you 60 models of building steel formwork, steel mold fixed method and fixed plate type fixed hole number

- U card is used in the calculation of the formula, in general, each square is about 15 U card

- Q: How does steel formwork affect the overall fire resistance of a structure?

- Steel formwork does not directly affect the overall fire resistance of a structure. Fire resistance primarily depends on the materials used for structural elements, such as beams, columns, and floors. However, steel formwork can indirectly contribute to fire resistance by ensuring the proper placement and alignment of concrete during construction, which can enhance the overall structural integrity and fire resistance of the building.

Send your message to us

Steel-Frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords