Steel-frame Formwork and Scaffolding System SF-140

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel-frame Formwork and Scaffolding System SF-140

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel-frame Formwork and Scaffolding System SF-140

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

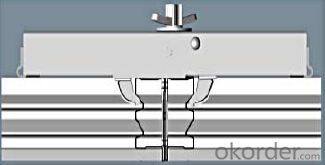

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

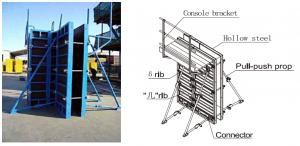

3. Steel-frame Formwork and Scaffolding System SF-140 Images

4. Steel-frame Formwork and Scaffolding System SF-140 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel-frame Formwork and Scaffolding System SF-140

1) What can we do for you?

.We can ensure the quality of the Steel-frame Formwork and Scaffolding System SF-140 and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel-frame Formwork and Scaffolding System SF-140, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork SF140 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel-frame Formwork and Scaffolding System SF-140, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:Can steel formwork be used for dam construction?

- Yes, steel formwork can be used for dam construction. Steel formwork is a versatile and durable option that is commonly used in various construction projects, including dams. It offers several advantages such as high strength, rigidity, and the ability to withstand the immense pressure and weight of concrete used in dam construction. Steel formwork can be easily assembled and disassembled, allowing for efficient and quick construction. Additionally, it provides a smooth and uniform finish to the concrete, ensuring the structural integrity and longevity of the dam.

- Q:How does steel formwork handle different concrete curing temperatures?

- Steel formwork is a highly durable and versatile construction material that is well-suited to handle different concrete curing temperatures. The key advantage of steel formwork is its ability to withstand high temperatures without deformation or structural damage. Concrete curing temperatures can vary depending on several factors, such as the climate, project specifications, and construction schedule. Steel formwork is designed to withstand these variations and maintain its structural integrity throughout the curing process. In instances where the concrete curing temperature is high, steel formwork effectively dissipates the heat due to its excellent thermal conductivity. This helps to prevent excessive heat buildup, which could potentially lead to premature curing or thermal cracking of the concrete. The steel formwork acts as a heat sink, absorbing and distributing the heat evenly, ensuring uniform curing throughout the concrete structure. On the other hand, steel formwork also performs well in low-temperature curing conditions. Its high tensile strength and rigidity allow it to withstand the pressure exerted by the cold concrete mix during the curing process. This prevents any distortion or deformation of the formwork, ensuring accurate and precise shaping of the concrete structure. Furthermore, steel formwork is also resistant to moisture and humidity, which are critical factors in curing concrete. It does not absorb water or release moisture, maintaining a consistent moisture content in the concrete during the curing process. This is particularly advantageous in areas with high humidity or where the curing time is extended. Overall, steel formwork is a reliable and robust material that can effectively handle different concrete curing temperatures. Its ability to dissipate heat, withstand cold temperatures, and resist moisture makes it a preferred choice for construction projects where temperature variations are a concern.

- Q:What are the different types of alignment systems used with steel formwork?

- There are several different types of alignment systems that are commonly used with steel formwork in construction projects. These alignment systems serve to ensure that the formwork is properly aligned and positioned, allowing for accurate and precise concrete placement. 1. Pin and wedge system: This is one of the most widely used alignment systems with steel formwork. It involves the use of steel pins, which are inserted into pre-drilled holes in the formwork panels, and wedges that are driven into the pins to secure the panels together. This system provides a strong and reliable connection, allowing for precise alignment. 2. Flat tie system: This alignment system uses flat ties, which are inserted through the formwork panels and secured using various methods such as nuts and washers or locking pins. The flat ties provide stability and alignment by connecting the formwork panels together. 3. Adjustable clamp system: This system utilizes adjustable clamps that are attached to the formwork panels. The clamps can be adjusted to achieve the desired alignment and are tightened to hold the panels in place. This system offers flexibility and ease of adjustment during the formwork installation process. 4. Strut and prop system: This alignment system involves the use of vertical struts and props to support and align the formwork panels. The struts are connected to the formwork panels and the props are used to adjust the height and alignment. This system is particularly useful for large or complex formwork structures. 5. Magnetic alignment system: This is a relatively new alignment system that utilizes magnets to hold the formwork panels together. The magnets are embedded in the formwork panels, allowing for quick and easy alignment without the need for additional tools or fasteners. This system offers convenience and speed in formwork installation. Overall, the choice of alignment system depends on factors such as the size and complexity of the formwork structure, the required level of precision, and the specific requirements of the construction project. Contractors and engineers select the most appropriate alignment system based on these considerations to ensure the successful installation and alignment of steel formwork.

- Q:Are there any environmental considerations when using steel formwork?

- Yes, there are several environmental considerations when using steel formwork. Firstly, steel production is energy-intensive and contributes to greenhouse gas emissions. However, steel formwork can be reused multiple times, reducing the need for new materials and minimizing waste generation. Additionally, proper disposal and recycling of steel formwork at the end of its lifespan is important to reduce environmental impact. Overall, while steel formwork has certain environmental drawbacks, its reusability and recyclability make it a more sustainable option compared to other formwork materials.

- Q:Can steel formwork be used for railway construction projects?

- Railway construction projects can indeed utilize steel formwork. Steel formwork proves to be a robust and adaptable material capable of withstanding the immense loads and pressures linked to railway construction. It offers a sturdy and inflexible framework for pouring concrete and shaping desired forms for various railway infrastructure components like tunnels, bridges, platforms, and retaining walls. The utilization of steel formwork in railway construction projects presents numerous advantages. Firstly, it boasts a remarkable capacity to bear heavy loads, enabling it to support both the weight of the concrete and any additional burdens. This attribute is particularly crucial in railway construction, as safety and stability are of utmost importance. Secondly, steel formwork is reusable, making it a cost-effective option for large-scale endeavors. It can be effortlessly disassembled, cleaned, and reassembled for future applications, reducing the need for additional formwork materials and minimizing waste. Furthermore, steel formwork guarantees exceptional dimensional accuracy and surface finish. It ensures that the resulting concrete structures are of superior quality and align with the required specifications and standards for railway construction. Additionally, steel formwork exhibits exceptional resistance to moisture, chemicals, and other environmental factors that may deteriorate the formwork material. This renders it suitable for both indoor and outdoor railway construction projects that often face exposure to harsh weather conditions. Overall, steel formwork stands as a dependable and efficient choice for railway construction projects. Its strength, reusability, dimensional accuracy, and resistance to environmental factors make it an ideal material for shaping and pouring concrete structures in railway infrastructure development.

- Q:What are the different types of coatings available for steel formwork panels?

- Steel formwork panels can be coated in various ways, each with its own advantages and uses. 1. Galvanized Coating: This type of coating is commonly used and involves applying a layer of zinc to the steel surface through galvanization. Galvanized coatings offer excellent resistance to corrosion, making them suitable for outdoor and high-moisture environments. 2. Epoxy Coating: Known for their exceptional chemical and abrasion resistance, epoxy coatings consist of resin and a hardener. They create a strong and durable surface that can withstand heavy use and exposure to chemicals, making them ideal for industrial settings or applications requiring high performance. 3. Polyurethane Coating: Polyurethane coatings are highly durable and provide excellent resistance to abrasion, impact, and weathering. They are commonly used in construction projects or infrastructure development where durability is essential. These coatings also adhere well to the steel surface, ensuring long-lasting protection. 4. Powder Coating: In this dry finishing process, a fine powder is electrostatically applied to the steel surface and then heat-cured to form a hard, protective layer. Powder coatings come in a variety of colors and offer excellent resistance to chipping, scratching, and fading. They are often used for aesthetic purposes or when a decorative finish is desired. 5. Zinc-rich Coating: Similar to galvanized coatings, zinc-rich coatings have a higher concentration of zinc particles. These coatings provide enhanced corrosion protection and are commonly used in highly corrosive environments such as marine or coastal areas. They can be applied through spraying or brushing. 6. Fire-resistant Coating: Specifically designed to prevent the spread of fire, fire-resistant coatings create a barrier that delays the heating of steel during a fire, reducing the risk of structural collapse. They are commonly used in commercial and industrial buildings, as well as in infrastructure projects. To ensure the best coating for steel formwork panels, it is important to consider the project's requirements and consult with experts. Factors such as the environment, expected durability, and budget should be taken into account to ensure optimal performance and longevity.

- Q:How does steel formwork handle different concrete curing time requirements?

- Steel formwork is highly versatile and can easily accommodate different concrete curing time requirements. It offers excellent strength and durability, allowing for extended curing periods without compromising the structural integrity. Additionally, steel formwork provides a smooth and rigid surface that aids in achieving a consistent curing process. It can be easily assembled and disassembled, allowing for efficient adjustments to accommodate specific curing time requirements. Overall, steel formwork is a reliable choice that effectively handles different concrete curing time requirements.

- Q:Can steel formwork be used for different types of concrete finishes?

- Indeed, various concrete finishes can be achieved through the utilization of steel formwork. With its remarkable versatility, steel formwork has the capability to be tailored in order to produce an array of concrete finishes such as sleek, textured, or patterned surfaces. By employing steel formwork, one can achieve precision in shaping and molding the concrete, thereby facilitating the creation of diverse finishes in accordance with the desired design and aesthetic specifications. Moreover, steel formwork can be effortlessly adapted and employed for different undertakings, rendering it a cost-efficient selection for attaining a wide range of concrete finishes.

- Q:Can steel formwork be used for foundation construction?

- Indeed, foundation construction can make use of steel formwork. Steel formwork proves to be a flexible and long-lasting alternative for the creation of foundations. It affords a solid and steady support system for the pouring of concrete and the achievement of the desired shape and structure of the foundation. Steel formwork presents various advantages, such as its easy assembly and disassembly, reusability, and capacity to withstand substantial loads and pressure. Moreover, steel formwork exhibits high resistance to moisture and can be effortlessly cleaned, rendering it suitable for application in foundation construction projects. All in all, steel formwork stands as a dependable and effective choice for the construction of foundations.

- Q:Can steel formwork be customized to specific project requirements?

- Yes, steel formwork can be customized to specific project requirements. Steel is a versatile material that can be easily molded and fabricated to meet the specific shape, size, and design requirements of a project. This allows for the creation of complex and unique formwork structures that can be used to cast concrete in various shapes and sizes. Additionally, steel formwork can be adjusted and modified during the construction process to accommodate any changes or alterations that may be required. This flexibility and adaptability make steel formwork an ideal choice for projects with specific and customized requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-frame Formwork and Scaffolding System SF-140

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords