HR sheet ! hot sales hot rolled carbons steel checker plate/sheet mild steel chequer plate/sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.General Introduction

Item name | Chequered steel plate | |

Standard | ASTM, JIS, GB | |

Grade | Gr1, Gr2, Gr3, Gr5, Gr7, Gr12 | |

Dimension | Hot rolled | Thk*W*L (4.1-60.0)*(400-3000)*(1000-7000)mm |

Cold rolled | Thk*W*L (0.3-4.0)*(400-1400)*(1000-4000)mm | |

Surface | Acid pickling | |

Application | Heat exchanger, chemical or medical industry | |

Advantages | High qualities, competitive price, strict inspection, prompt delivery. | |

2.Chemical Requirements

| N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti | |

Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | / | / | / | / | / | bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5-6.75 | 3.5-4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12-0.25 | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2-4.0 | 0.6-0.9 | bal |

3.Tensile Properties

| Grade | Tensile Strength(min) | Tensile Strength(min) | Yield Strength(min) | Yield Strength(min) | Elongation(%) |

| Ksi | Mpa | Ksi | Mpa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr3 | 65 | 450 | 55 | 380 | 18 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 20 |

| Gr9 | 90 | 620 | 70 | 438 | 15 |

| Gr12 | 70 | 438 | 50 | 345 | 18 |

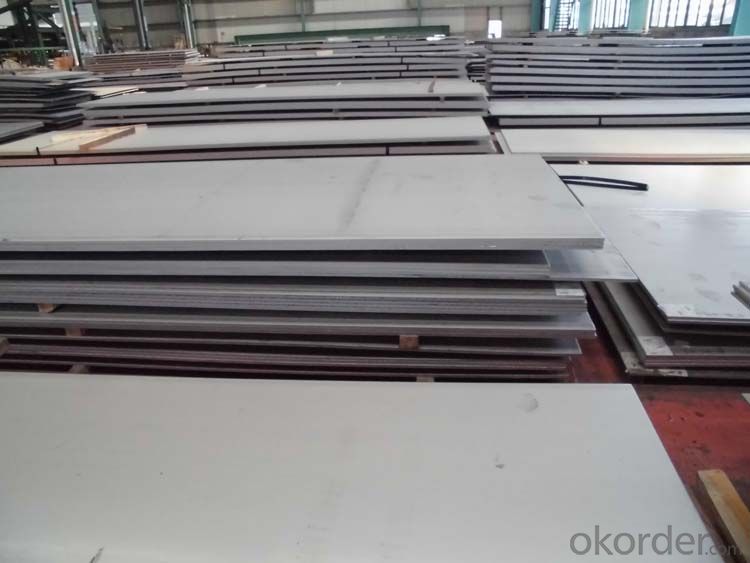

4.Production

5.Product

Packaging & Shipping

- Q: How do steel sheets perform in cryogenic environments?

- Steel sheets perform well in cryogenic environments. Cryogenic temperatures, typically below -150°C (-238°F), can cause materials to become brittle and lose their strength. However, steel is known for its excellent toughness and can withstand low temperatures without significant degradation. Steel sheets are commonly used in cryogenic applications due to their ability to maintain structural integrity and resist fracture. They exhibit good thermal conductivity, which allows them to effectively transfer heat from the environment and prevent cold spots that could compromise the material's strength. Furthermore, steel's low coefficient of thermal expansion minimizes the risk of dimensional changes caused by extreme temperature variations. This property is crucial in cryogenic environments where precision and stability are required. Additionally, steel resists embrittlement, a phenomenon that affects certain materials when exposed to cryogenic temperatures for extended periods. Some materials become more susceptible to fracture due to the diffusion of hydrogen or other gases into their lattice structure. Steel, however, has a high resistance to embrittlement, making it a reliable choice for cryogenic applications. In summary, steel sheets perform admirably in cryogenic environments. They maintain their structural integrity, resist embrittlement, and minimize dimensional changes, making them a suitable material for various applications in industries such as aerospace, energy, and research.

- Q: What is the composition of steel sheets?

- Steel sheets are primarily composed of iron and carbon, with small amounts of other elements such as manganese, phosphorus, sulfur, and silicon. The exact composition may vary depending on the specific grade and intended use of the steel sheet.

- Q: What are the different alloying elements used in steel sheets?

- To enhance the properties and performance of steel sheets, various alloying elements are utilized. Some commonly employed alloying elements are as follows: 1. Carbon: Being the most crucial alloying element, carbon imparts strength and hardness to the steel. It also enhances its heat-treatability, making it suitable for diverse applications. 2. Manganese: For improved mechanical properties like strength and toughness, manganese is frequently added to steel sheets. It also aids in reducing brittleness. 3. Chromium: Steel sheets are enriched with chromium to augment their corrosion resistance. By forming a thin protective layer on the steel's surface, it prevents rusting and corrosion. 4. Nickel: Nickel is commonly incorporated into steel sheets to enhance their toughness and impact resistance. It also improves their ability to withstand extreme temperatures, rendering them suitable for high-temperature applications. 5. Silicon: The addition of silicon to steel sheets improves their strength and hardness. It also aids in deoxidizing the steel during the manufacturing process. 6. Vanadium: Vanadium serves as an alloying element in steel sheets to enhance strength, toughness, and heat resistance. It also refines the grain structure of the steel, making it more uniform and fine. 7. Copper: Copper is included in steel sheets to enhance corrosion resistance and thermal conductivity. It also improves the weldability and brazability of the steel. 8. Tungsten: Tungsten is utilized as an alloying element in steel sheets to enhance hardness, strength, and wear resistance. In small quantities, it is often added to improve cutting and drilling capabilities. These examples highlight just a few of the alloying elements commonly employed in steel sheets. The selection of alloying elements depends on the specific requirements of the application and the desired properties of the steel. Different combinations and concentrations of these elements can be employed to achieve a wide range of characteristics in steel sheets.

- Q: Can steel sheets be used for noise barriers?

- Indeed, noise barriers can indeed utilize steel sheets. Steel, being a resilient and sturdy substance, can effectively hinder or diminish the propagation of sound waves. Its substantial density and mass aid in the absorption and reflection of sound, thereby impeding its passage through the barrier. It is possible to tailor and produce steel sheets specifically for the purpose of noise reduction, incorporating attributes like perforations or acoustic insulation materials to enhance their efficacy. Moreover, steel sheets can be treated with coatings or paint to bolster their resistance against adverse weather conditions and corrosion. In general, steel sheets present a feasible choice for the construction of noise barriers, particularly in locales with elevated levels of noise pollution.

- Q: How are steel sheets protected during transportation by sea?

- To ensure the safety and prevent damage of steel sheets during transportation by sea, various measures are taken. One commonly used method involves applying a protective coating to the sheets. This coating acts as a barrier against moisture and saltwater, which are the main culprits behind corrosion during sea transportation. The coating can be a temporary solution, such as a layer of oil or wax, or a more permanent option, such as a layer of paint or zinc. Moreover, steel sheets are often bundled or placed in shipping containers for added protection. These bundles are secured with straps or wires to prevent movement and potential damage in rough sea conditions. The shipping containers themselves are designed to withstand the challenges of sea transportation and shield the steel sheets from exposure to the elements. Additionally, the sheets may be wrapped in plastic or other waterproof materials to provide an extra layer of defense against moisture. This helps prevent direct contact with seawater or rain, thus reducing the risk of corrosion. During the loading and unloading processes, proper handling techniques are employed to minimize the risk of damage. Cranes or forklifts are carefully used to lift and move the steel sheets, ensuring that they are not dropped or subjected to excessive force that could cause dents or bends. Overall, a combination of protective coatings, secure packaging, and proper handling techniques is utilized to safeguard steel sheets during sea transportation. This reduces the likelihood of damage and ensures that they reach their destination in optimal condition.

- Q: What is the typical cost of steel sheets compared to aluminum?

- Compared to aluminum, steel sheets generally have a lower typical cost. Steel, known for its strength, durability, and affordability, is widely used in construction and manufacturing. Steel sheets are easily obtained in various grades and thicknesses, making them more economically advantageous. Conversely, aluminum, a lightweight and corrosion-resistant metal, is highly sought after in industries like aerospace and automotive. However, the production and processing of aluminum are more expensive than steel, resulting in higher costs for aluminum sheets. Ultimately, the price disparity between steel and aluminum sheets hinges on factors such as market demand, current metal prices, and specific project or application requirements.

- Q: How do steel sheets perform in terms of electrical conductivity?

- Steel sheets are not good conductors of electricity compared to materials like copper or aluminum. While steel does conduct electricity, it has a relatively high resistance, which limits its ability to efficiently transmit electrical current.

- Q: What is the cost of a standard steel sheet?

- The cost of a standard steel sheet can vary depending on factors such as size, thickness, and market conditions. It is advisable to check with suppliers or conduct market research to get accurate pricing information.

- Q: What is the thickness tolerance for steel sheets?

- The thickness tolerance for steel sheets can vary depending on the specific grade of steel and the manufacturing process. In general, the industry standard for steel sheet thickness tolerance is typically ±0.005 inches (0.13 mm). However, it is important to note that different applications and industries may have their own specific tolerance requirements. Therefore, it is essential to consult the relevant standards and specifications for the specific steel sheet being used to determine the appropriate thickness tolerance. Additionally, some manufacturers may offer tighter tolerances based on customer requirements or specialized applications.

- Q: What is the hardness of the steel sheets?

- The specific grade and treatment of steel can cause variations in the hardness of steel sheets. The Rockwell hardness scale is commonly used to measure the resistance of steel sheets to indentation. The hardness of steel sheets can vary greatly, ranging from soft to extremely hard, and is influenced by factors like carbon content, alloying elements, and heat treatment methods employed in manufacturing. When choosing steel sheets, it is crucial to consider the intended application and desired properties, as the hardness can impact wear resistance, strength, and machinability.

Send your message to us

HR sheet ! hot sales hot rolled carbons steel checker plate/sheet mild steel chequer plate/sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords