Hot Rolled Carbon Steel Checker Plate/Sheet Mild Steel Chequer Plate/Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Commodity Name | GRADES |

Boiler and Pressure Vessel Steel Plates | Q245R,Q345R,Q370R,15CrMoR,18MnMoNbR,13MnNiMoR, 12Cr1MoVR,12Cr2Mo1R,14CrMoR, |

16MnDR,09MnNiDR,15MnNiDR | |

07MnCrMoVR,07MnNiCrMoVDR/12MnNiVR | |

SB410,SB450,SB480 | |

SPV235,SPV315,SPV355,SPV410,SPV490 | |

SGV41O,SGV450,SGV480 | |

SBV1A,SBV1B,SBV2,SBV3 | |

SEV245,SEV295,SEV345 | |

HI,HII,10CrMo910,15Mo3,13CrMo44,19Mn6 | |

BHW35/13MnNiMo54 | |

1Cr0.5Mo,2.25Cr1Mo,1.25Cr0.5Mo,Q245R|Q345R(HIC)/(R-HIC) | |

(s)A229M, (s)A515M(Gr.A,B,C), (s)A387M(GR11,12,22), (s)A537M(GL1,GL2), (s)A662M(GrA,B,C), (s)A302M(GraA,B,C,D), (s)A737M(Gr.B,C), (s)A738M(Gr.A,B,C), (s)A533M(Ⅰ,Ⅱ), (s)A285Gr:A,B,C,D | |

P235GH,P265GH,P395GH,P355GH,16Mo3 | |

A42,A52,A48 | |

20MnHR,Q245HR,Q345HR,KP42,AISI4140,A48CPR,SA612M | |

161G430 | |

WDB620/Q500FC | |

Low Alloy High Strength Steel Plate | 12Mn,15MnVN,16Mn,15MnV,14MnNb |

Q295(A,B),Q345(A,B,C,D,E)Q390(A,B,C,D,E), Q420(A,B,C,D,E),Q460(C,D,E) | |

Q500(D,E),Q550(D,E),Q620(D,E),Q690(D,E) | |

SM490(A,B,C),SM490Y(A,B),SM520(B,C),SM570 | |

St44-3,St52-3,St50-2, St60-2,St70-2 | |

StE315,StE355,StE380,STe420,StE460,StE500 | |

A572M(Gr42.50,60,65),A633M9(A,B,C,D,E) | |

S275(JR,JO,J2G3,J2G4),S355(JR,JO,J2G3,J2G4,E395,E355,E360) | |

S275N,S275NL,S355N,S355NL,S420N,S420NL,S460N,S460NL | |

50(A,B,C,D,DD,EE,F),43(A,B,C,D,EE),55(C,EE,F) | |

Fe430(A,B,C,D),Fe510(B,C,D) | |

WH60,WH410LK(BB41BF),WH490LK(BB503),Q550CFC | |

WDB690,WDB780,WH70,WH80 IE0650,IE1006,SHT60 | |

Corrision Resistance Steel Plate | 08Cu,16MnCu,Q245R|Q345R(HIC)\(R-HIC) |

St37-3Cu3 | |

A588M(A,B,C,K),A242MCL.2 | |

Cor-TenB,10CrMoAL | |

16CuCr,12MnCuCr,15MnCuCr-QT,09CuPCrNi | |

SMA400(AW,BW,CW),SMA400(AP,BP,CP),SMA490(AW,BW,CW) SMA490(AP,BP,CP),SMA570W,SMA570P | |

Fe235W,Fe355W,WR50B,WR50C | |

Bridge Steel Plate | 16q,16Mnq,16MnCuq/15MnVq,15MnVNq 14MnNbp/Q345q,Q370q,Q420q |

A709M(Gr36,50,50W,70W) | |

Construction, Structural Steel Plate | Q235GJ,Q345GJC.D-Z35,Q390GJ,Q460GJC |

SN400(A,B,C),SN490(B,C) | |

275(D,E,EZ),355(D,E,EM),450(EM,EMZ) | |

Alloy Structure Steel Plate | 15CrMo,20CrMo,30CrMo,35CrMo,20Cr, 40Cr,20Mn2,40Mn2,20CrMnMo,12Cr1MoV,20MnSi 30CrMnSiA,12CrMoVNi(RQ65),50Mn2V,42CrMo |

25CrMo4,34CrMo4,42CrMo4 | |

Mold Wear Steel Plate | P20,718,P80,WSM30A |

S45C-S55C | |

45-55,50Mn,SM45-SM55,SM3Cr2Mo,SM3Cr2Mo,SM3Cr2Ni1Mo | |

NM360,NM400 | |

Carbon Structure Steel Plate | Q235-Q275 |

10-55,20Mn-50Mn | |

SS400/SM400(A,B) | |

S10C-S55C | |

St37-2,St37-3 | |

A36,A283(A,B,C,D),1010-1050 | |

40(A,B,C,D,E) | |

S235(JR ,JO ,J2G3,J2G4) | |

1C22,1C25,1C30,1C35,1C40,1C45,1C50,1C55 | |

Fe360(A,B,C,D) | |

Bridge Oil Flatform Steel Plate | A,B,D,E(Z15,Z25,Z35) AH32-FH32(Z15,Z25,Z35) AH36-FH36(Z15,Z25,Z35) |

D40,E40 | |

AP1 SPEC 2H Gr42,Gr50 | |

Complex Steel Plate | TU1/20g 0Cr13Ni5Mo/Q235A 0Cr13Ni5Mo/16Mn |

High Strength Yield Steel Plate | GS80 28Cr2Mo(GY4) 26SiMnMo(GYS) 30CrMnMoRE(603) 30CrNi3MoV(675) |

Oil, Gas Line Steel Plate | X42,X46,X52,X56 X60,X65,X70,X80 |

| Commodity | Cheap Price tear drop checker steel plate Q235B 5.75*1250 steel plate for road Tianjin | ||||||||

| Width | 1250mm or cut to size | ||||||||

| Thickness |

5.75mm | ||||||||

| Surface | coated | ||||||||

| Material | Cheap Price tear drop checker steel plate Q235B 5.75*1250 steel plate for road Tianjin | ||||||||

| Standards | AISI ASTM JIS DIN EN and GB | ||||||||

| Certifications | ISO 9001and SGS | ||||||||

| Applications | All can be used as steel plate | ||||||||

| Packing | Seaworthy wooden pallet or according to client's requirement | ||||||||

| Place of origin | Tianjin, China | ||||||||

| Paymentterms | L/C or T/T | ||||||||

| Delivery time | Up to order quantity | ||||||||

Detailed Images

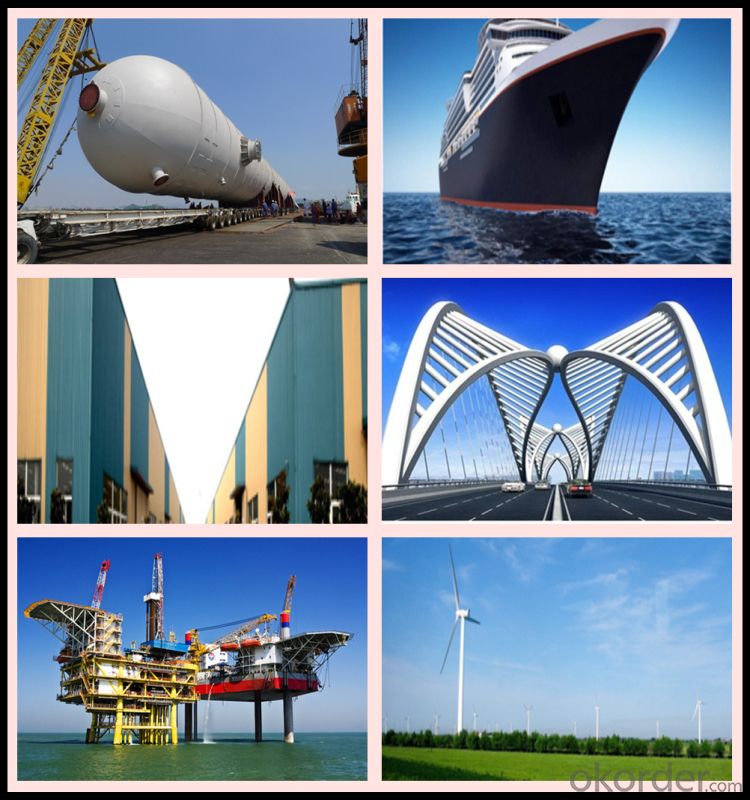

Product Uses

- Q: What are the different coil cutting methods used for steel coils?

- There are several coil cutting methods commonly used for steel coils, each with its own advantages and applications. These methods include shearing, slitting, and laser cutting. 1. Shearing: Shearing is a widely used method for cutting steel coils. It involves applying a high force to a set of blades, which cuts through the coil in a straight line. Shearing is ideal for cutting thick steel coils into smaller, more manageable sizes. It is a cost-effective method that can be used for high-volume production. 2. Slitting: Slitting is a process that involves cutting a wide coil into several narrower strips. This method is commonly used for steel coils that need to be transformed into various widths, such as those used in the manufacturing of automotive components, construction materials, and electrical appliances. Slitting machines use a set of circular knives to make precise cuts, ensuring minimal material loss and high accuracy. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser beam to cut through steel coils. This process offers exceptional precision, allowing for intricate designs and complex shapes to be cut with ease. Laser cutting is suitable for thin to medium thickness steel coils and is often used in industries that require high-quality cuts, such as automotive, aerospace, and electronics. Each of these coil cutting methods has its own advantages and is chosen based on the specific requirements of the steel coils being processed. Factors such as coil thickness, desired accuracy, production volume, and the complexity of the cuts needed are all taken into account when determining the most appropriate cutting method.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: How are steel coils different from steel sheets?

- Steel coils and steel sheets are both made from the same material, which is steel. However, they differ in terms of their shape and size. Steel coils are long, continuous rolls of steel, usually wound up in a coil form, while steel sheets are flat, rectangular pieces of steel. The main difference lies in their applications - steel coils are commonly used in industries where large quantities of steel are required for manufacturing processes, such as automotive or construction, whereas steel sheets are often used for smaller-scale projects or as a raw material for further processing.

- Q: What are the different methods of embossing steel coils?

- There are numerous techniques for embossing steel coils, each possessing unique characteristics and applications. Some of the most prevalent techniques include: 1. Hot embossing: By heating the steel coil to a high temperature and pressing it between two engraved rollers, this method allows for intricate designs or textures to be imprinted onto the surface. The heat softens the steel, facilitating the desired pattern transfer. 2. Cold embossing: In contrast to hot embossing, cold embossing does not require heating the steel coil. Instead, it employs pressure and specifically designed dies or stamps to produce the desired pattern. Cold embossing is commonly used for simpler designs or when working with heat-sensitive materials. 3. Roller embossing: This technique involves using a series of rollers with engraved patterns to imprint the design onto the steel coil. The coil is passed through the rollers, and the applied pressure transfers the pattern onto the surface. Roller embossing is often utilized for larger-scale production, delivering consistent and uniform results. 4. Laser embossing: A modern method that employs laser technology to create patterns on steel coils. The laser beam selectively melts or vaporizes the metal, generating the desired design. Laser embossing offers high precision and flexibility, making it suitable for intricate and detailed patterns. 5. Press embossing: This technique utilizes a press machine equipped with custom-made dies to imprint the desired pattern onto the steel coil. The coil is positioned between the dies, and the press machine applies pressure, transferring the pattern onto the surface. Press embossing is commonly used for large-scale production, achieving high-speed and high-volume embossing. Ultimately, the choice of embossing method depends on various factors, including design complexity, production volume, material properties, and cost considerations. Each technique possesses advantages and limitations, necessitating careful selection by manufacturers based on their specific requirements.

- Q: What are the different types of steel coil recoiling methods?

- There are several different types of steel coil recoiling methods, including oscillating recoiling, flying shear recoiling, and rotary recoiling.

- Q: I am a complete idiot when it comes to anything musical, so please forgive me if this is a stupid question. I bought my son his first guitar, acoustic and didnt realize until after I purchased it that it has steel strings. Can I have the strings changed from steel to nylon???

- Haha, You're too cute for me. Did you buy Alex the guitar? Just wait until your boys become the next Jonas Brothers :)

- Q: this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- it sometimes rusts

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- 154cm is a very good knife steel, the problem is in the heat treating. Stainless should be cryo treated to get all it can offer. That being said, if you really want to drop some coin, look at getting one made from CPM 440V. Stainless isn't as strong as carbon but on a smaller knife works well. You might also look for D-2 Tool steel. There are factory knives that are made of that.

- Q: I beat fallout 3 and i downloaded broken steel expansion. I have no idea how to get to broken steel in other words i do not know how to start playing it.

- after-wards you will have to sit through the end movie, which I felt was longer than the original, then the broken steel part will start, which I wont ruin. If your still having problems, go into your DLC and delete broken steel, and re-install it.

- Q: How are steel coils used in the manufacturing of pressure vessels?

- Steel coils are used in the manufacturing of pressure vessels as they are processed into flat sheets and then formed into the desired shape. These coils provide strength and durability to the pressure vessel, ensuring it can withstand high pressures and temperatures.

Send your message to us

Hot Rolled Carbon Steel Checker Plate/Sheet Mild Steel Chequer Plate/Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords