Mild Steel Chequered Plate MS checker Plate Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,JIS

Technique:

Hot Rolled

Shape:

Round

Surface Treatment:

Coated,Oiled,Dry

Steel Grade:

Q195,Q215,Q235,SS400-SS490

Certification:

ISO,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

requirement

Net Weight:

23mt

Packaging:

Standard Export Packing

1.General Introduction

| Production Name | Hot Rolled Steel Chequered Sheet |

| Loading Port | Any Port in China |

| Thickness | 1.8mm-16mm |

| Width | 1000mm-1600mm |

| Coil Weight | 28 mt max |

| Material Grade | SS400\Q235\SAE1006\SAE1008 |

| Technique | Hot Rolled |

| Standard | GB \JIS\ASTM |

| Test | With Hydraulic Testing, Eddy Current , Infrared Test |

| Surface | 1) Bared |

| 2) Oiled | |

| Package | Standard Export Packing,Or at Customer’s Requirement |

| Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

| Payment | 100% L/C at sight, 30% T/T in advance |

| Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

| Certificate | ISO |

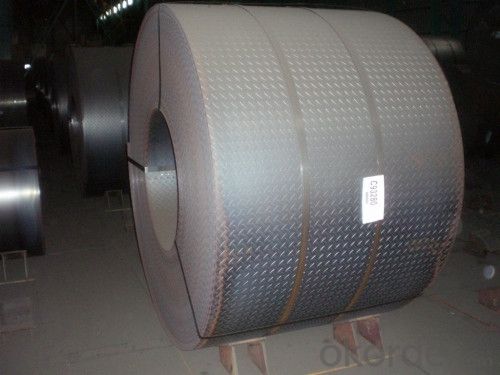

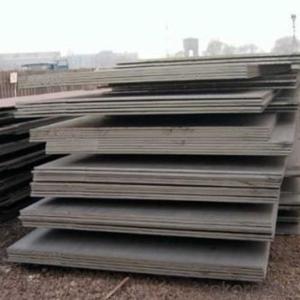

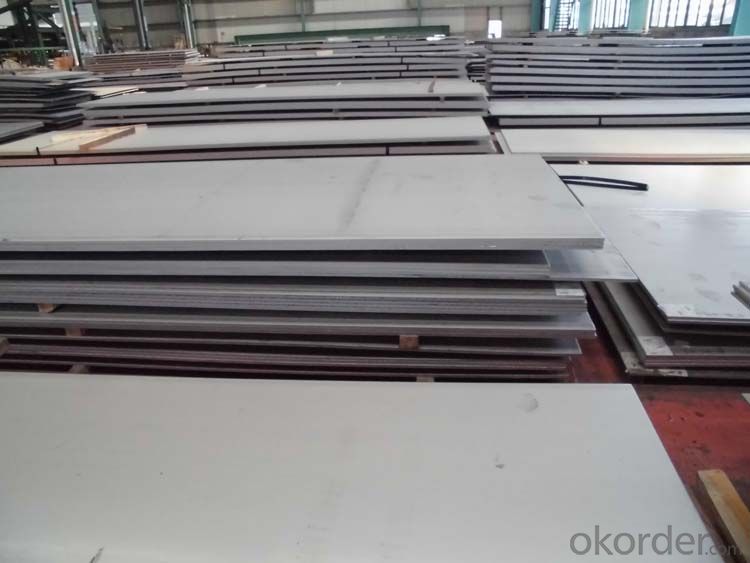

2.Product Photo

3.Our Service

- Q: My company want to welding stainless steel, do not know to use what welding machine?

- Stainless steel is a fascinating metal to weld. Welding stainless can be difficult if you don't know what you are doing. It reacts to excessive heat by warping and distorting once it cools. Everything shows up in stainless. If you weld with too much heat you can see it by the heat marks left in the metal along with any distortion. It also scratches very easily so you must take care when welding on a metal table. Stainless steels can be welded using several different procedures such as shielded metal arc welding, gas tungsten arc welding, and gas metal arc welding but stainless steel welding wires have been developed for welding stainless steels.

- Q: What are the different methods of oiling steel coils?

- There are several different methods of oiling steel coils, each with its own unique advantages and applications. Some of the common methods include: 1. Immersion or bath oiling: This method involves submerging the steel coils into a bath of oil. The coils are typically passed through a series of rollers to ensure even coating and complete coverage. Bath oiling is a cost-effective and efficient method for large-scale production, as it can oil multiple coils simultaneously. This method is commonly used for hot-rolled coils. 2. Roll-on oiling: As the name suggests, roll-on oiling involves applying oil to the surface of steel coils using a set of rotating rollers. This method ensures uniform oil distribution and is suitable for both cold-rolled and hot-rolled coils. Roll-on oiling is often preferred when precise control over the amount of oil applied is required. 3. Spray oiling: In spray oiling, a fine mist or spray of oil is applied to the coils using specialized nozzles or sprayers. This method allows for targeted application, making it suitable for specific areas or sections of the steel coils. Spray oiling is commonly used for precision or specialty coils where controlling the amount of oil is critical. 4. Electrostatic oiling: Electrostatic oiling involves applying a charged mist of oil particles to the steel coils. The coils are given an opposite charge, causing the oil particles to be attracted and adhere to the surface. This method ensures an even and controlled distribution of oil, minimizing waste and reducing environmental impact. Electrostatic oiling is often used for high-quality or high-precision applications. 5. Brush or roller oiling: This method involves manually applying oil to the coils using brushes or rollers. It is typically used for smaller-scale operations or when precision is required in specific areas. Brush or roller oiling allows for close control over the amount of oil applied. The choice of oiling method depends on various factors such as the type of steel, desired level of oil coverage, production volume, and cost considerations. Each method has its own advantages and limitations, and manufacturers often select the most suitable method based on their specific requirements and objectives.

- Q: How are steel coils used in the production of electrical relays?

- Steel coils are used in the production of electrical relays as they provide the necessary magnetic field required for the relay to function. When an electric current passes through the coil, it generates a magnetic field, which then attracts or repels the relay's switch mechanism. This coil-based mechanism allows relays to control the flow of electricity in various electrical circuits.

- Q: What are the common applications of steel coils in construction?

- Steel coils are commonly used in construction for a variety of applications such as roofing, wall cladding, structural beams, and framing components. They provide strength, durability, and versatility, making them ideal for supporting and reinforcing various structures and ensuring their stability and longevity.

- Q: Can steel coils be coated with copper?

- Yes, steel coils can be coated with copper. This process, known as copper coating or copper plating, involves applying a thin layer of copper onto the surface of the steel coils to enhance their corrosion resistance, conductivity, and aesthetics.

- Q: Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- Steel-type Pokemon are strong against Ice and Rock-type Pokemon, weak against Fire, Fighting, and Ground-type moves, resistant to Dark, Dragon, Ghost, Grass, Ice, Normal, Psychic, Rock, and Steel-type moves, and are immune to Poison-type moves. Notable Steel-type Pokemon include Skarmory, Scizor, and Metagross. Dark-type Pokemon are strong against Ghost and Psychic-type Pokemon, weak against Bug and Fighting-type moves, resistant to Ghost-type moves, and immune to Psychic-type moves. Notable Dark-type Pokemon include Houndoom, Murkrow, and Sneasel. Steel-type Pokemon have more resistances than Dark-types, but more weaknesses as well. In truth, no one type is better than any other, and making a team composed entirely of a single type may make some battles difficult. It's best to keep your options open, and go with a wide variety of types.

- Q: Can steel coils be bent or formed into different shapes?

- Steel coils have the capability to be bent or molded into diverse forms. Typically, steel coils are produced from flexible flat rolled steel, allowing for easy manipulation. The process of bending entails exerting force upon the steel coil, resulting in a transformation of shape and the adoption of different configurations. This can be accomplished through a variety of techniques, including cold or hot bending, as well as the utilization of specialized machinery such as a press brake. By skillfully applying the appropriate amount of force and heat, steel coils can be bent or molded into an extensive array of shapes, encompassing curves, angles, and intricate geometries. This adaptability in shaping steel coils renders them exceptionally versatile for an array of applications, spanning construction, manufacturing, automotive, and numerous other industries.

- Q: How are steel coils used in the manufacturing of automotive accessories?

- Steel coils are commonly used in the manufacturing of automotive accessories due to their strength, durability, and versatility. These coils serve as the primary raw material for various components and parts used in the automotive industry. One of the most common uses of steel coils in automotive accessory manufacturing is for the production of body panels and frames. These coils are formed and shaped into the desired size and design, and then undergo various processes such as cutting, stamping, and welding to create the body panels and frames of vehicles. The high strength of steel coils ensures that the body panels and frames are sturdy enough to withstand the rigors of daily use and provide the necessary structural integrity to the vehicle. Additionally, steel coils are also used in the production of automotive suspension systems. Coil springs, which are integral components of the suspension system, are typically made from steel coils due to their ability to absorb and distribute the weight and impact of the vehicle. These coil springs contribute to a smooth and comfortable ride by providing the necessary support and shock absorption. Furthermore, steel coils are used in the manufacturing of automotive accessories such as exhaust systems, brackets, and brackets for various components. The coils are formed and shaped into the required design and then undergo processes like cutting, bending, and welding to create these accessories. The strength and durability of steel make these accessories capable of withstanding high temperatures, vibrations, and other harsh operating conditions. In summary, steel coils play a crucial role in the manufacturing of automotive accessories by providing the necessary strength, durability, and versatility required for various components and parts. From body panels to suspension systems and accessories, steel coils contribute to the overall quality, performance, and safety of automotive accessories.

- Q: What is the process for uncoiling and recoiling steel coils?

- The process for uncoiling and recoiling steel coils involves various steps. Firstly, the steel coil is securely placed on a mandrel or a coil car. Next, the coil is unfastened or cut to release the bands holding it together. Then, a suitable uncoiling machine is used to gradually unwind the coil, ensuring it is done in a controlled manner to prevent damage or accidents. Once the desired length of steel is unwound, it can be cut or sheared to the required size. To recoil the steel, it is fed through a recoiling machine that winds it back onto a new core or mandrel. Proper tension is applied during this process to ensure a tightly wound coil. Finally, the recoiled steel coil is secured with bands or straps for transportation or storage purposes.

- Q: What are the safety considerations when handling steel coils?

- There are several safety considerations that should be taken into account when dealing with steel coils. Firstly, it is crucial to wear the correct personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots. This protective gear helps minimize the risk of injuries from sharp edges, flying debris, or accidental contact with the coils. Secondly, it is important to have a clear understanding of the weight and dimensions of the steel coils being handled. Steel coils can be extremely heavy, and improper lifting techniques can lead to back strains, muscle pulls, or even more severe injuries. Therefore, it is crucial to employ proper lifting techniques, such as bending the knees and maintaining a straight back, or using lifting equipment like cranes or forklifts when necessary. Moreover, steel coils can be unstable and susceptible to rolling or shifting during handling. To avoid accidents, it is vital to secure the coils adequately before moving or stacking them. This can be achieved by using appropriate lifting attachments, binding the coils together, or utilizing racks or other storage systems specifically designed for steel coils. Additionally, it is important to be aware of the potential hazards associated with the steel coils, such as sharp edges, oil or grease coatings, or even damage to the coils themselves. It is essential to inspect the coils for any irregularities or defects before handling them, as well as ensuring that they are stored safely and securely to prevent accidents. Lastly, proper communication and training are crucial when dealing with steel coils. Establishing clear channels of communication between workers is essential to ensure that everyone is aware of their roles and responsibilities. Furthermore, providing training on safe handling techniques, potential hazards, and emergency procedures can significantly reduce the risk of accidents and injuries. In conclusion, when handling steel coils, it is important to wear the appropriate PPE, employ proper lifting techniques, secure the coils adequately, be mindful of potential hazards, and ensure effective communication and training. By adhering to these safety considerations, the risk of accidents and injuries can be greatly diminished.

Send your message to us

Mild Steel Chequered Plate MS checker Plate Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords