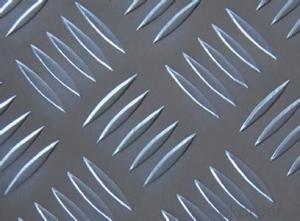

Polishing Aluminum Checker Plate

Polishing Aluminum Checker Plate Related Searches

Polishing Checker Plate Aluminum Polished Aluminum Checker Plate Polishing Aluminum Diamond Plate Polishing Diamond Plate Aluminum Checker Plate Aluminum Aluminum Checkered Plate Diamond Checker Plate Aluminum Black Aluminum Checker Plate Polishing Aluminum Foil Polished Aluminum Plate Aluminium Checkered Plate Aluminum Checker Plate For Sale Aluminum Diamond Plate Polish Aluminum Checker Plate Sheet 1 4 Aluminum Checker Plate Painting Aluminum Plate Aluminum Checker Plate Price Checker Plate Aluminum Price Diamond Plate Aluminum Polish Polished Aluminum Diamond Plate Checker Plate Aluminum Sheets 1 8 Aluminum Checker Plate Aluminum Checker Plate Near Me Painting Aluminum Diamond Plate 1/8 Aluminum Checker Plate 4x8 Aluminum Checker Plate Welding Aluminum Plate Aluminum Checker Plate Suppliers Polished Aluminum Tread Plate Polishing Aluminum Foil BallPolishing Aluminum Checker Plate Supplier & Manufacturer from China

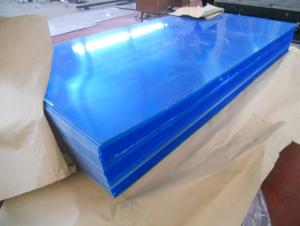

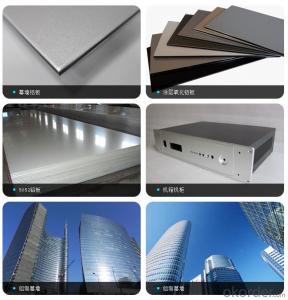

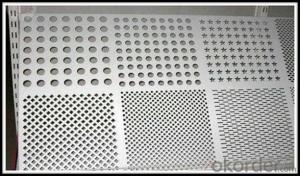

Polishing Aluminum Checker Plate is a type of aluminum sheet material that has undergone a special finishing process to achieve a smooth, polished surface. This product is known for its durability, corrosion resistance, and aesthetic appeal, making it a popular choice for various applications.The Polishing Aluminum Checker Plate is widely used in a range of industries and applications, including construction, automotive, aerospace, and interior design. Its slip-resistant surface and modern appearance make it ideal for use in flooring, stair treads, and wall cladding, as well as for decorative purposes in both commercial and residential settings. Additionally, its lightweight nature and strength make it a preferred choice for manufacturing components in the automotive and aerospace sectors.

Okorder.com is a reputable wholesale supplier of Polishing Aluminum Checker Plate, offering a vast inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Polishing Aluminum Checker Plate they provide meets the highest industry standards.

Hot Products