Mill Finished Aluminum Coil Plate for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

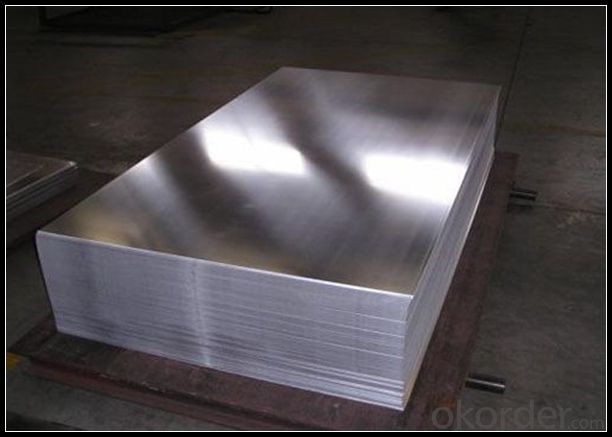

1. Structure of Mill Finished Aluminium Sheet for Punching Description

Mill Finished Aluminium Sheet for Punching is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet for Punching

Mill Finished Aluminium Sheet for Punching | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

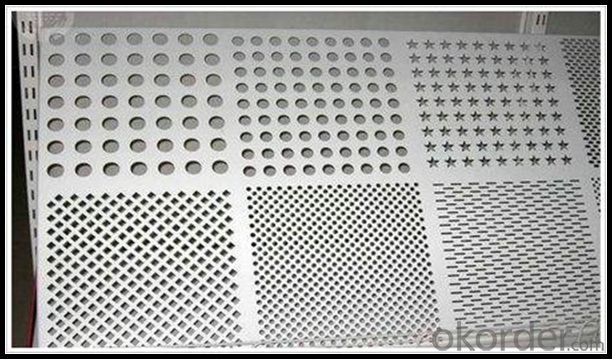

3. Application of Mill Finished Aluminium Sheet for Punching

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet for Punching

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet for Punching

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

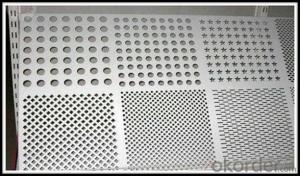

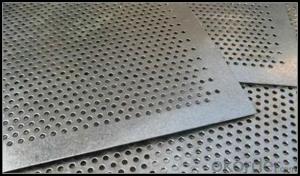

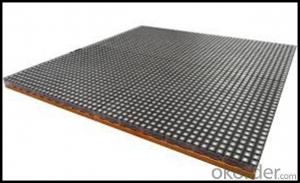

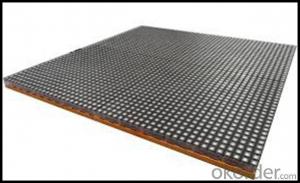

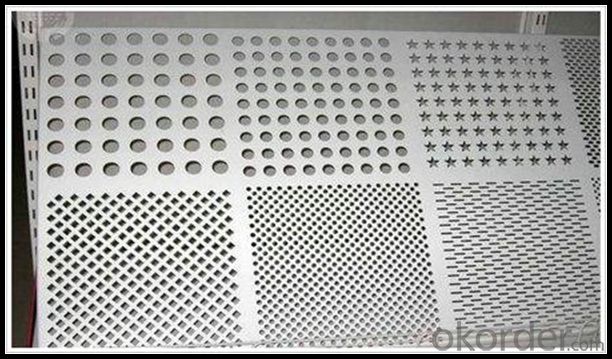

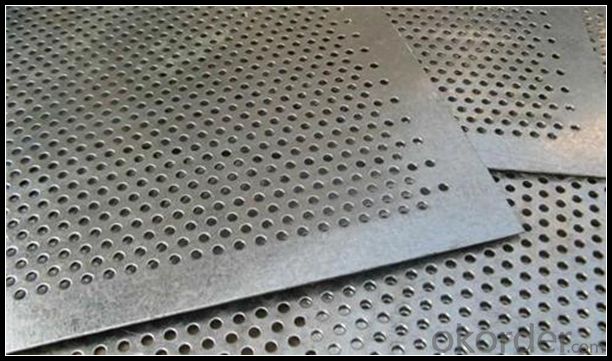

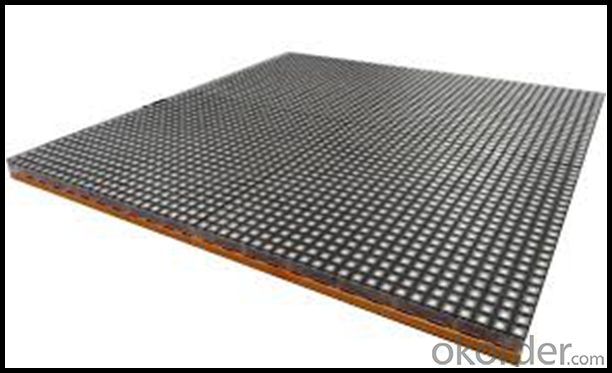

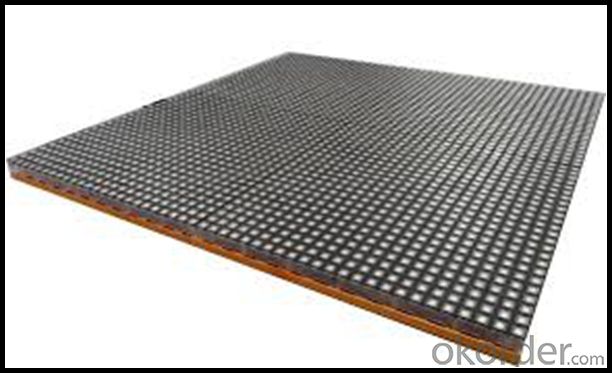

6. Image of Mill Finished Aluminium Sheet for Punching

7. Package and shipping of Mill Finished Aluminium Sheet for Punching

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to energy-efficient appliances?

- Aluminum coils contribute to energy-efficient appliances by enhancing the heat transfer process. Due to their high thermal conductivity, aluminum coils facilitate the rapid transfer of heat, allowing appliances such as air conditioners, refrigerators, and heat pumps to operate more efficiently. This improved heat transfer ensures that the appliances require less energy to achieve the desired cooling or heating effect, ultimately reducing overall energy consumption and promoting energy efficiency.

- Q: Are aluminum coils suitable for lightweight panel applications?

- Yes, aluminum coils are suitable for lightweight panel applications due to their inherent lightweight nature and high strength-to-weight ratio. Additionally, aluminum coils offer excellent corrosion resistance, making them a reliable choice for various lightweight panel applications.

- Q: What are the common surface treatments for aluminum coils in the automotive industry?

- Aluminum coils in the automotive industry undergo various surface treatments to improve their performance and appearance. Some popular treatments include anodizing, painting, cladding, clear coating, and polishing/buffing. Anodizing is a widely used treatment that forms a protective oxide layer on the surface of the coils. This is achieved by immersing the coils in an electrolytic solution and applying an electric current. Anodizing enhances corrosion resistance, durability, and allows for dye or paint application. Painting is another option for aluminum coil treatment, providing both aesthetics and protection against environmental factors. Coils are coated with either solvent-based or powder paint, offering an appealing appearance and safeguarding against scratches and UV radiation. Cladding involves bonding a layer of aluminum alloy with different properties onto the coil's surface. This treatment is commonly employed to enhance strength, thermal conductivity, or corrosion resistance. Cladding methods can include hot rolling, cold rolling, or explosive bonding. Clear coating is often applied to aluminum coils to create a transparent protective layer. This coating prevents corrosion, oxidation, and discoloration, while preserving the natural metallic appearance. Polishing and buffing are surface treatments that aim to improve the smoothness and shine of aluminum coils. Imperfections, scratches, and oxidation are mechanically removed through grinding or polishing. These methods are often used for decorative purposes in high-end automotive applications. These are merely a few examples of the surface treatments available for aluminum coils in the automotive industry. The choice of treatment depends on factors such as desired appearance, performance requirements, and environmental conditions the coils will face.

- Q: im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- Aluminum. When you hit the ball, it goes farther then a wooden bat. That is why MLB players can't use them, just in case of a line drive to the pitcher. They have enough problems dodging it, and this would get a lot more of them hit.

- Q: When you are cooking fish? I ran out of aluminum foil, all I have is parchment paper on hand. Does it matter or affect the way the fish gets cooked? Just wondering what the difference is, if any.

- Just wrap the fish in the parchment and you will be fine. It won't be as air-tight as the aluminum, and it is a lot more flimsey, so the fish may not steam as well, but it will be fine.

- Q: I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- No way!! because of the fact inspite of the bat, the helmet and the shin guards the undergo is plenty larger than a human and is going to basically get mad from the bat and kill you. Nope $800,000 isn't something for that!

- Q: Is it advisable to purchase and utilize recycled aluminum coils without initial quality assessment?

- <p>No, it is not safe to buy and use recycled aluminum coils without first checking their quality. Recycled aluminum coils may have inconsistencies in thickness, strength, and purity, which can affect the performance and safety of the final product. It's crucial to inspect the coils for any defects, impurities, or deviations from the required specifications to ensure they meet the standards necessary for your application. Quality control is essential to prevent failures, maintain safety, and uphold the integrity of your manufacturing process.</p>

- Q: What types of aluminum coil are best suited for specific applications?

- <p>Yes, different types of aluminum coil are better suited for specific applications. For instance, 1100 series aluminum coil, known for its high purity and excellent formability, is ideal for applications requiring deep drawing or bending. The 3003 series is often used for applications needing good corrosion resistance and formability, such as automotive parts and chemical equipment. The 5052 series offers a balance of strength and corrosion resistance, making it suitable for marine applications and aircraft structures. The 6061 series is known for its strength and is often used in construction and transportation industries. Each series has unique properties that make it more suitable for certain applications, so selection should be based on the specific requirements of the project.</p>

- Q: i dont want aluminum cookware, but how about a stainless steel set with an aluminum core. Is this the same as aluminum pots and pans? Thanks.

- The aluminum is encased in the stainless steel, usually as a thick disk in the bottom. It is an excellent conductor of heat and holds the heat well once it gets hot. All you see is the stainless, none of the aluminum because it's between two layers of stainless in the bottom of the pots. You are right, you don't want food cooked in straight aluminum, some metal taste can transfer to certain foods. That won't happen with stainless.

- Q: What are the different types of aluminum coils available in the market?

- There are several different types of aluminum coils available in the market, each with its own unique characteristics and applications. 1. Plain Aluminum Coils: These are basic aluminum coils that are typically used for general applications. They have a smooth surface and are often used in construction, automotive, and packaging industries. 2. Color Coated Aluminum Coils: These coils are coated with a layer of paint or other finishes to enhance their aesthetic appeal and provide additional protection against corrosion. They are commonly used in the manufacturing of building facades, signage, and decorative applications. 3. Embossed Aluminum Coils: These coils have a textured or patterned surface, which gives them a decorative and non-slip finish. They are often used in applications where aesthetics and functionality are important, such as flooring, staircases, and decorative panels. 4. Anodized Aluminum Coils: These coils undergo an anodizing process, where a protective oxide layer is formed on the surface of the aluminum. This enhances their corrosion resistance and makes them suitable for outdoor applications, such as architectural elements, electronic components, and aerospace industry. 5. Pre-painted Aluminum Coils: These coils come with a pre-applied paint coating, which eliminates the need for additional painting or finishing. They are commonly used in industries that require high-quality, durable, and color-consistent products, such as automotive, appliances, and electronics. 6. Heat Exchanger Aluminum Coils: These coils are specifically designed for heat transfer applications, such as air conditioning and refrigeration systems. They have a high thermal conductivity and are often made from alloy grades that offer excellent corrosion resistance in harsh environments. It is important to consider the specific requirements and intended use of the aluminum coil before making a purchase. This will help ensure that the appropriate type of coil is selected for the desired application, thereby optimizing performance and longevity.

Send your message to us

Mill Finished Aluminum Coil Plate for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords