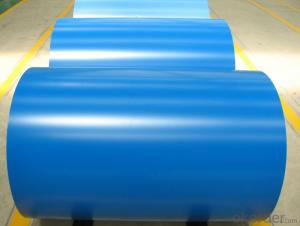

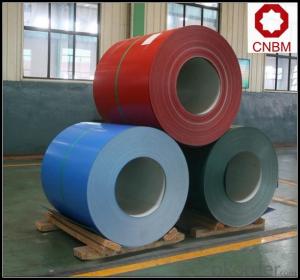

Prefinished Aluminum Coil

Prefinished Aluminum Coil Related Searches

Hot Searches

Oak Veneer Plywood Price Veneer Plywood Suppliers Used Marine Plywood For Sale Marine Plywood For Sale Plywood Prices In Pune Wholesale Plywood Prices Plywood Sheets Prices Oak Faced Plywood Prices 6Mm Marine Plywood Prices Cheapest Plywood Prices Mivan Shuttering Cost AnalysisPrefinished Aluminum Coil Supplier & Manufacturer from China

Okorder.com is a professional Prefinished Aluminum Coil supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Prefinished Aluminum Coil firm in China.Hot Products

FAQ

- Yes, aluminum coils are prone to corrosion. Aluminum is a reactive metal that easily forms a protective oxide layer when exposed to oxygen. However, this oxide layer can be compromised by certain environmental factors, such as exposure to moisture, salt, or other corrosive substances. Over time, this can lead to the formation of corrosion on the surface of aluminum coils. Regular maintenance and proper care, such as cleaning and applying protective coatings, can help mitigate the risk of corrosion.

- Yes, aluminum coils are generally resistant to fire due to their high melting point and low flammability.

- An aluminum coil is a long, flat, and thin sheet of aluminum that is rolled up into a coil shape. It is typically made from high-quality aluminum alloys that are durable, lightweight, and corrosion-resistant. Aluminum coils have a wide range of applications across various industries. One of the most common uses is in the manufacturing of aluminum products, such as cans, containers, and packaging materials. The flexibility and malleability of aluminum coils make them ideal for shaping into different forms and sizes. Additionally, aluminum coils are extensively used in the construction industry for various purposes. They are commonly used for roofing, siding, gutters, and other exterior applications due to their ability to withstand harsh weather conditions and resist corrosion. The lightweight nature of aluminum coils makes them easier to handle and install, reducing labor and transportation costs. Moreover, aluminum coils are also used in heating, ventilation, and air conditioning (HVAC) systems. They are utilized in the production of condenser and evaporator coils, which are crucial components for controlling temperature and humidity in residential, commercial, and industrial buildings. In summary, an aluminum coil is a versatile and valuable material that finds widespread use in numerous industries. Its lightweight, corrosion-resistant, and malleable properties make it an excellent choice for manufacturing aluminum products, as well as for construction and HVAC applications.

- To clean and maintain aluminum coils, you can follow a few simple steps. First, gather the necessary materials, including a soft brush or vacuum cleaner, a mild detergent or coil cleaner, a water hose, and a spray bottle. Start by turning off the power supply to the unit and ensuring that it is safe to proceed. Next, remove any debris or loose dirt from the coils using a soft brush or a vacuum cleaner with a brush attachment. Be gentle to avoid damaging the fragile fins of the coils. Once the loose dirt is removed, mix a solution of mild detergent or coil cleaner with water in a spray bottle. Spray the solution onto the coils, ensuring that it covers the entire surface. Let it sit for a few minutes to allow the solution to penetrate the dirt and grime. After the solution has had time to work, use a soft brush or a soft cloth to gently scrub the coils. Be careful not to apply excessive pressure or use abrasive materials, as this could cause damage. Pay extra attention to any areas with stubborn dirt or buildup. Once you have thoroughly cleaned the coils, rinse them off with a water hose. Ensure that all the detergent or coil cleaner is completely washed away. Make sure to direct the water flow in the opposite direction of the air flow to avoid pushing debris further into the coils. After rinsing, allow the coils to dry completely before turning the power supply back on. This will prevent any potential electrical hazards. You can use a fan or leave the coils to air dry naturally. To maintain the cleanliness of the coils, it is recommended to clean them at least once a year or more frequently if the unit is exposed to heavy dirt or debris. Regularly inspecting the coils for dirt buildup and promptly cleaning them will help maintain the efficiency and extend the lifespan of the aluminum coils.

- Some safety precautions required when handling aluminum coils include wearing protective gloves and safety glasses to prevent cuts and eye injuries, ensuring proper lifting techniques to avoid strain or back injuries, storing coils in a secure manner to prevent them from falling or rolling, and keeping the work area clean and free from any potential trip hazards. Additionally, it is important to be aware of the sharp edges of the coils and handle them with care to avoid any injuries.

- Aluminum coils contribute to sustainability efforts by being highly recyclable, energy-efficient, and durable. They can be recycled repeatedly without losing their properties, reducing the need for virgin aluminum production and minimizing waste. Additionally, aluminum coils have a low weight-to-strength ratio, resulting in energy savings during transportation. Their durability ensures a longer lifespan, reducing the frequency of replacements and the associated environmental impact. Overall, aluminum coils play a crucial role in promoting a more sustainable and circular economy.

- Which is better composite or aluminum, and what are some main differences between the two?

- I believe that composite is a lot better, I bought the orange easton stealth bat and I love it. Once they are broken in, composite is deadly. But Its really bad to use a composite bat in the cold because they dent easier. I recommend one piece aluminum for cold weather like the easton v12 or the tpx omaha. Easton sv12's are good too, but its not one piece aluminum. You just have to remember that a metal bat is a metal bat and its if you are a good hitter, it wont really matter what you use.

- How can aluminium ingots be processed into aluminium coils (aluminium sheets)?

- This depends on what kind of ingot, and if it is small, it needs to be melted into a furnace, cast into a large plate, and then rolled on a mill