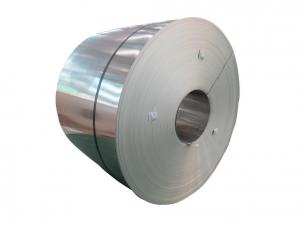

Aluminum Cast Coil 1050,1100,3003,5753,5083,6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

aluminum coil specifications:

1) Alloy :1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 6mm

4) Width:20mm to 3300mm

5)Coil weight: 100kgs to 6 tons depends on actual requirement

6)Core material: Aluminum or paper

7)Coil Inner diameter: 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required

8) Protective film can be added

Application

Appplication:construction, roofing, decoration, lamping etc

Packaging & Shipping

Package: eye to wall or eye to the wall for aluminum coil with wood pallet (wooded case also available)

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Aluminum sheets are indeed appropriate for utilization in the food processing and packaging sectors. The food industry extensively employs aluminum due to its exceptional properties and advantages. To begin with, aluminum is a safe material for direct contact with food as it is non-toxic. It does not react with food or affect its taste, guaranteeing the preservation of the original flavor and quality. This is particularly crucial in packaging, as it aids in maintaining the freshness and integrity of the food product. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient and uniform heat distribution during food processing. This attribute is advantageous in cooking, baking, and other thermal procedures, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets exhibit outstanding barrier properties, including resistance to moisture, light, and gases. This shields food from external factors that could potentially degrade its quality, such as moisture or oxygen. It also extends the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet sturdy and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and safeguards the food during transportation and storage. Lastly, aluminum is an environmentally sustainable material. It is fully recyclable, meaning it can be reused without losing its properties. This aids in reducing the environmental impact and supports the concept of a circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available, including plain, embossed, perforated, and painted aluminum sheets.

- Q: Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination is a process of bonding multiple layers together to create a composite material with enhanced properties. In the case of aluminum sheets, they can be laminated with other materials such as plastics, adhesives, or even other metals. This process can improve the strength, durability, and thermal or electrical conductivity of the aluminum sheets. Laminated aluminum sheets are commonly used in various industries, including construction, automotive, aerospace, and packaging, where the combination of different materials provides the desired characteristics for specific applications.

- Q: Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting. Aluminum is a commonly used material in laser cutting due to its excellent reflective properties, high thermal conductivity, and low melting point. These characteristics make it an ideal material to be cut by a laser beam. Laser cutting provides precise and clean cuts on aluminum sheets, allowing for intricate designs and complex shapes to be easily achieved. Additionally, laser cutting of aluminum sheets is a fast and efficient process, offering high productivity and cost-effectiveness.

- Q: Explain the similarities and differences in the properties of aluminum metal, Al(s) and aluminum oxide (a salt) Al203(s) in terms of the particles and forces present.. thanks doods!

- Aluminum metal is not found in nature, only aluminum oxide is in the mine or ground and they have to separate it from the oxidation to make a useful metal.

- Q: Are the aluminum sheets suitable for automotive applications?

- Yes, aluminum sheets are suitable for automotive applications. Aluminum is a lightweight material with high strength-to-weight ratio, making it ideal for use in the automotive industry. It offers several advantages such as improved fuel efficiency, better handling, and increased performance. Additionally, aluminum is resistant to corrosion, which is beneficial for automotive applications as it helps increase the lifespan of vehicles. Moreover, aluminum sheets can be easily formed and molded into various shapes, allowing for greater design flexibility in automotive manufacturing. Overall, the use of aluminum sheets in automotive applications has become increasingly popular due to their numerous advantages and positive impact on vehicle performance and sustainability.

- Q: Is it possible to use aluminum sheets as an insulating material for walls in new construction projects?

- <p>Aluminum sheets themselves are not typically used for wall insulation due to their poor insulating properties. Aluminum is a good conductor of heat, which makes it unsuitable for insulation as it can transfer heat easily, leading to energy loss. However, aluminum can be used as a vapor barrier or as part of a composite material in combination with proper insulation. For effective insulation, materials with low thermal conductivity like fiberglass, cellulose, or foam are commonly used.</p>

- Q: Are aluminum sheets suitable for packaging applications?

- Yes, aluminum sheets are highly suitable for packaging applications due to their lightweight, corrosion-resistant, and excellent barrier properties. They can effectively protect products from moisture, light, and oxygen, ensuring longer shelf life and freshness. Additionally, aluminum sheets are easily formable, making them suitable for various packaging formats like cans, foils, and pouches.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

- Q: Aluminum plate belongs to steel or non ferrous metal?

- Metal materials fall into two broad categories: ferrous and non-ferrous metals. What we usually call "iron and steel" is ferrous metal; copper and aluminum are nonferrous metals.

Send your message to us

Aluminum Cast Coil 1050,1100,3003,5753,5083,6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords