Aluminum Composite Panel Sheets - High Quality Aluminum Coil 1050 1060 1070 1100 3003 3105 5052 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

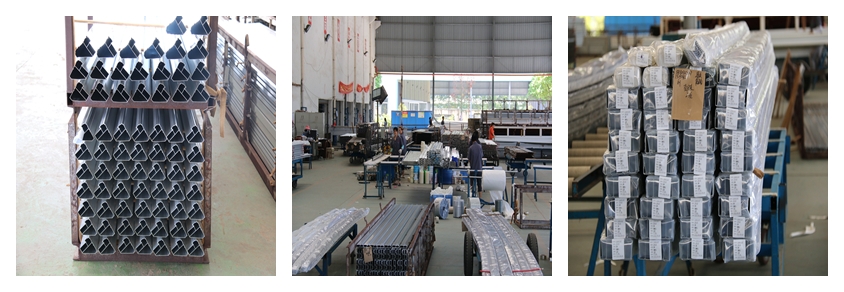

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Are aluminum sheets suitable for outdoor use?

- Indeed, aluminum sheets are well-suited for utilization outdoors. With its exceptional durability and resistance to corrosion, aluminum emerges as an optimal material for outdoor purposes. Despite its lightweight nature, aluminum exhibits remarkable strength, enabling it to endure severe weather conditions including rainfall, snowfall, and the harmful effects of UV radiation. Furthermore, aluminum sheets can be coated or painted, amplifying their resistance to corrosion and furnishing supplementary safeguarding against environmental elements. Consequently, aluminum sheets have garnered significant popularity in the domain of outdoor construction, signage, roofing, and various other exterior applications where endurance and longevity are paramount.

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q: It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- Even though it's a keepsake, you might think of switching to stainless steel. It's questionable whether the aluminum is healthy since elements of the metal may taint your food and get into your body.

- Q: What specific considerations or precautions need to be taken into account when working with thin aluminum sheets?

- <p>When working with thin aluminum sheets, it's important to handle them carefully to prevent denting or bending. Use gloves to avoid oils and moisture from hands that can cause corrosion. Ensure proper ventilation when cutting or shaping to avoid inhaling aluminum dust. Use sharp tools to minimize the risk of tearing or marring the surface. Also, consider the specific alloy's properties, as different aluminum alloys have varying strengths and malleabilities. Always follow safety guidelines and use appropriate protective equipment.</p>

- Q: Is it possible to utilize aluminum sheets in the construction of furniture?

- <p>Yes, aluminum sheets can be used for furniture. They are lightweight, durable, and resistant to corrosion, making them suitable for various types of furniture such as outdoor furniture, tables, chairs, and shelving. Aluminum's strength and flexibility allow for creative designs and easy maintenance. Additionally, it is a sustainable material that can be recycled, contributing to environmental sustainability.</p>

- Q: What is the thermal conductivity of aluminum sheets?

- The thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin.

- Q: Can the aluminum sheets be used for manufacturing aircraft engine components?

- Yes, aluminum sheets can be used for manufacturing aircraft engine components. Aluminum is a commonly used material in the aerospace industry due to its excellent strength-to-weight ratio and corrosion resistance. It is lightweight, yet strong enough to withstand the stresses and high temperatures associated with aircraft engines. Additionally, aluminum sheets can be easily fabricated, making them suitable for producing intricate engine components. Overall, aluminum sheets are a preferred choice for manufacturing aircraft engine components due to their favorable mechanical properties and suitability for aerospace applications.

- Q: What is the weight of an aluminum sheet?

- Depending on its dimensions and thickness, an aluminum sheet may have varying weights. Due to its lightweight nature, aluminum sheets generally possess lower weights in comparison to other metals. In order to determine the weight of an aluminum sheet, it is necessary to possess knowledge regarding its length, width, and thickness. By multiplying the dimensions with the density of aluminum (2.7 g/cm³ or 0.0975 lb/in³), one can ascertain the estimated weight of the sheet.

- Q: How to polish aluminum sheet to be bright?

- as for polishing, fine grit sandpaper can't polish it into a mirror,but laser cutting can do it.

- Q: Are aluminum sheets suitable for lighting fixtures?

- Yes, aluminum sheets are suitable for lighting fixtures. Aluminum is a versatile and durable material that is commonly used in the manufacturing of lighting fixtures. It offers several advantages that make it a popular choice for this purpose. Firstly, aluminum is lightweight, which makes it easier to handle and install lighting fixtures. It is also highly corrosion-resistant, ensuring that the fixtures can withstand various environmental conditions without deteriorating or rusting over time. Additionally, aluminum has excellent thermal conductivity, allowing it to efficiently dissipate heat generated by the lighting fixtures, which helps in preventing overheating and prolonging their lifespan. Moreover, aluminum can be easily shaped and formed into various designs, making it ideal for creating aesthetically pleasing lighting fixtures. It can be extruded, rolled, or stamped to achieve different shapes and sizes, allowing for a wide range of creative possibilities. Furthermore, aluminum is a cost-effective material compared to other metals commonly used in lighting fixtures, such as brass or copper. It is readily available and has a lower price point, making it a more affordable option for both manufacturers and consumers. In summary, aluminum sheets are indeed suitable for lighting fixtures due to their lightweight nature, corrosion resistance, excellent thermal conductivity, versatility in design, and cost-effectiveness.

Send your message to us

Aluminum Composite Panel Sheets - High Quality Aluminum Coil 1050 1060 1070 1100 3003 3105 5052 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords