Automotive Grade Hot Rolled Aluminum Coil 5005H14 - Aluminum Coil Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Hot Rolled Aluminium Coil 5005H14 for Automotive

Name | Aluminum Coil |

Brand | CNBM |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

2. Application of Hot Rolled Aluminium Coil 5005H14 for Automotive

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Hot Rolled Aluminium Coil 5005H14 for Automotive

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

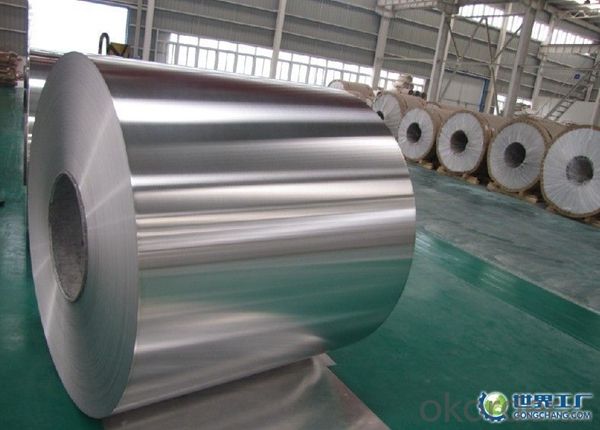

5. Image of Hot Rolled Aluminium Coil 5005H14 for Automotive

6. Package and shipping of Hot Rolled Aluminium Coil 5005H14 for Automotive

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to use a soldering iron to join aluminum coil with solder?

- <p>Traditional soldering irons are not suitable for soldering aluminum coils because aluminum does not readily bond with common solders used for irons. Aluminum has a high oxide layer that forms quickly, which prevents the solder from adhering. Specialized aluminum solder or fluxes are required for this task, and even then, the process might not be as effective as with other metals. For aluminum, brazing or welding techniques are often more appropriate.</p>

- Q: How are aluminum coils cleaned and maintained?

- Aluminum coils are typically cleaned and maintained by following a few key steps. Firstly, any loose debris or dirt should be removed using a soft brush or vacuum cleaner. Then, a mild detergent solution or a specialized coil cleaner can be applied to the coils, followed by gentle scrubbing with a soft brush to remove any stubborn dirt or grime. It is important to rinse off the cleaning solution thoroughly using a hose or pressure washer, ensuring no residue is left behind. Regular maintenance includes checking for any signs of damage or corrosion, and if required, applying a protective coating or lubricant to prevent future issues.

- Q: What are the proper storage methods to maintain the quality of aluminum coil for future use?

- <p>To store aluminum coil for future use, ensure it is kept in a cool, dry place away from direct sunlight and moisture. Stack the coils on flat, level surfaces with appropriate padding to prevent damage. Avoid stacking with other metals to prevent galvanic corrosion. Use clean, dry hands or gloves when handling to prevent oil and dirt from contaminating the surface. Store in a controlled environment with a relative humidity below 65% and a temperature between 32掳F to 90掳F (0掳C to 32掳C). Regularly inspect the coils for any signs of corrosion or damage.</p>

- Q: Can aluminum coils be used in the production of automotive body panels?

- Yes, aluminum coils can be used in the production of automotive body panels. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for automotive applications. The use of aluminum coils helps to reduce the weight of the vehicle, resulting in improved fuel efficiency and overall performance.

- Q: This question asks for a comparison of various types of equipment used for welding aluminum coils, highlighting their distinct features and applications.

- <p>Aluminum coil welding equipment varies based on technology, power source, and application. TIG (Tungsten Inert Gas) welders are known for high-quality welds and are ideal for thin aluminum coils. MIG (Metal Inert Gas) welders are versatile and suitable for thicker coils, offering faster welding speeds. Stick welders are more portable and cost-effective but produce lower quality welds. Laser welders provide precise, deep penetration welds suitable for high-precision applications. Friction stir welding is a solid-state process that offers excellent joint properties without melting the metal. Each type has its advantages and is chosen based on the specific requirements of the welding task, such as material thickness, weld quality, and production rate.</p>

- Q: How long do aluminum coils last?

- The lifespan of aluminum coils can vary depending on various factors such as maintenance, usage, and environmental conditions. On average, well-maintained aluminum coils can last between 15 to 20 years. However, with proper care and regular cleaning, some aluminum coils have been known to last even longer, up to 30 years or more. It is important to note that regular maintenance, such as cleaning the coils, checking for any damage or corrosion, and ensuring proper airflow, can significantly extend the lifespan of aluminum coils. Additionally, factors like exposure to harsh weather conditions, humidity levels, and the quality of installation can also impact the longevity of aluminum coils.

- Q: What are the different coil edge profiles available for aluminum coils?

- There are several different coil edge profiles available for aluminum coils. Some of the most common ones include: 1. Slit edge: This is the most basic type of edge profile, where the coil is simply slit to the desired width. The edges of the coil are typically sharp and can be prone to burrs or roughness. 2. Deburred edge: In this profile, the edges of the coil are deburred to remove any sharp or rough edges. Deburring helps to improve safety and prevents damage to downstream equipment during processing. 3. Rounded edge: This profile features rounded edges, which are achieved by rolling or machining the edges of the coil. Rounded edges are often preferred in applications where safety is paramount or where the coil will be subjected to frequent handling. 4. Beveled edge: Beveled edge profiles are created by cutting or grinding the edges of the coil at an angle. This profile is commonly used in applications where two coils need to be joined together, as the beveled edges allow for a smoother and more secure connection. 5. Custom edge profiles: Depending on the specific requirements of the application, custom edge profiles can be developed. These profiles are tailored to meet the unique needs of the customer and may involve a combination of different edge treatments. It is important to note that the choice of coil edge profile depends on the intended application, processing requirements, and desired aesthetic appearance. Manufacturers and suppliers of aluminum coils often offer a range of edge profiles to meet various customer needs.

- Q: Are aluminum coils suitable for electrical conductors?

- Aluminum coils, indeed, prove to be suitable for electrical conductors. Due to its remarkable electrical conductivity, aluminum has become a widely utilized material in the electrical industry. It possesses approximately 61% conductivity in comparison to copper, the utmost commonly employed metal for electrical conductors. Lightweight, cost-effective, and possessing good thermal conductivity, aluminum coils have become a favored selection for a range of electrical applications. Nonetheless, it is noteworthy that aluminum has a lower tensile strength than copper, thus potentially demanding a larger cross-sectional area to attain an equivalent level of current carrying capacity. Furthermore, to prevent oxidation and guarantee efficient electrical conductivity in aluminum coils, it is imperative to employ proper insulation and connectors.

- Q: What specific conditions or considerations need to be taken into account when utilizing aluminum coils in high-temperature settings?

- <p>When using aluminum coils in high-temperature environments, it's crucial to consider the material's melting point, which is around 660掳C (1220掳F). Ensure that the operating temperature does not exceed this threshold to avoid deformation or failure. Additionally, aluminum's strength and conductivity can be affected by high temperatures, so it's important to account for potential changes in performance. Protective coatings or treatments may be necessary to prevent oxidation and maintain the coil's integrity. Always consult material specifications and consult with material science experts to determine the suitability of aluminum coils for specific high-temperature applications.</p>

- Q: What is the maximum operating temperature for aluminum coils?

- The specific grade of aluminum used typically determines the maximum operating temperature for aluminum coils. Generally, aluminum has a high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), allowing it to endure high temperatures without melting or distorting. For common grades of aluminum, the maximum operating temperature usually ranges from 200 to 300 degrees Celsius (392 to 572 degrees Fahrenheit). However, it is important to consider factors like coil thickness and the intended application, as these can affect the temperature range. In instances where higher temperatures are anticipated, it is advisable to employ aluminum alloys specifically engineered to withstand such conditions. Aluminum alloy 6061, for example, can tolerate maximum operating temperatures of up to 400 degrees Celsius (752 degrees Fahrenheit) or even higher. To guarantee safe operation within temperature limits, it is always recommended to consult the manufacturer's specifications and guidelines for the specific aluminum coils being utilized.

Send your message to us

Automotive Grade Hot Rolled Aluminum Coil 5005H14 - Aluminum Coil Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords